Vacuum drying method of large square lithium battery pole group

A technology for vacuum drying and lithium batteries, applied in battery electrodes, electrode manufacturing, electrode heat treatment, etc., can solve problems such as poor battery short circuit, limited baking efficiency, and unsatisfactory baking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

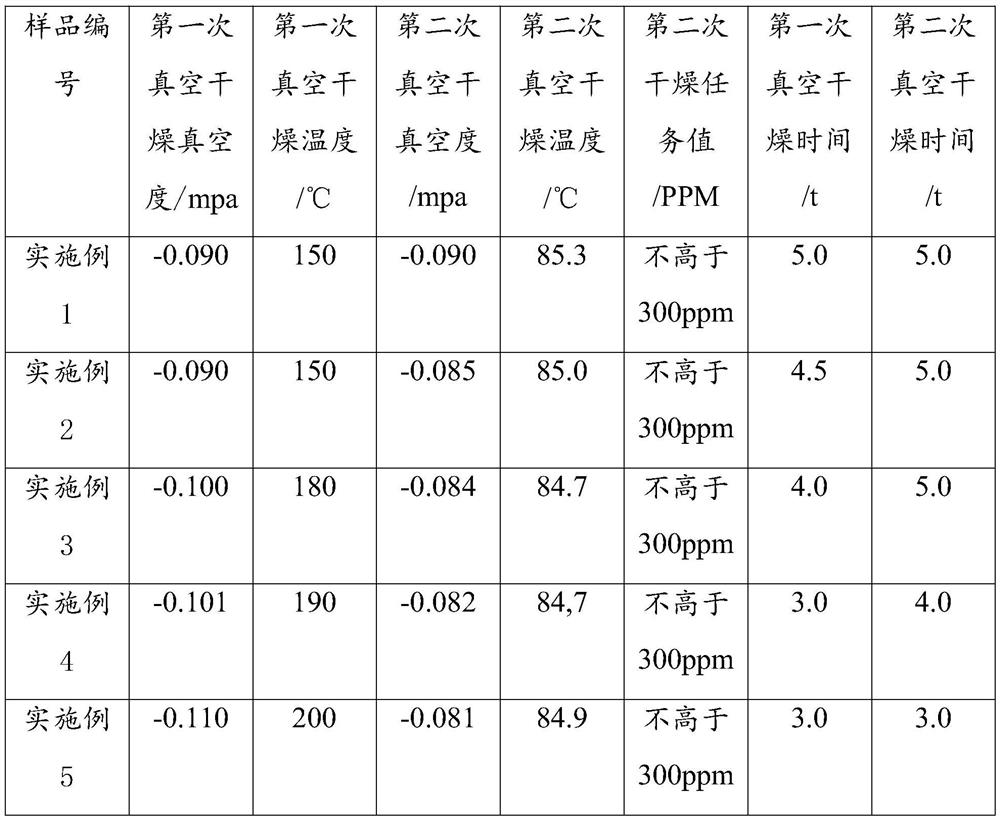

Embodiment 1

[0025] In this embodiment, a vacuum drying method for a large square lithium battery electrode assembly is provided, comprising the following steps:

[0026] The unassembled positive electrode sheet and negative electrode sheet are vacuum-dried for the first time, and the water surface content of the positive electrode sheet and negative electrode sheet is detected. The temperature of the first vacuum drying is 150 ° C, and the vacuum degree of the first vacuum drying is - 0.090mpa;

[0027] Assemble the square cell in the order of the positive electrode sheet, separator, and negative electrode sheet in sequence. After the liquid is injected, the cell is vacuum-dried for the second time. The temperature of the first vacuum drying is 85°C. Vacuum degree of vacuum drying -0.090mpa;

[0028] The second vacuum drying is divided into two stages, a stage constant vacuum drying, and a variable vacuum drying stage based on the constant vacuum drying, and the variable vacuum degree dr...

Embodiment 2

[0032] In this embodiment, a vacuum drying method for a large square lithium battery electrode assembly is provided, comprising the following steps:

[0033] Based on embodiment 1, further shorten the time of vacuum drying for the first time, concrete steps are as follows:

[0034] The unassembled positive electrode sheet and negative electrode sheet are vacuum-dried for the first time, and the water content on the surface of the positive electrode sheet and negative electrode sheet is detected. The temperature of the first vacuum drying is 150 ° C, and the vacuum degree of the first vacuum drying is - 0.090mpa;

[0035] Assemble the square cell in the order of the positive electrode sheet, separator, and negative electrode sheet in sequence. After the liquid is injected, the cell is vacuum-dried for the second time. The temperature of the first vacuum drying is 85°C. The vacuum degree of vacuum drying is not higher than -0.085mpa. ;

[0036] The second vacuum drying is div...

Embodiment 3

[0039] In this embodiment, a vacuum drying method for a large square lithium battery electrode assembly is provided, comprising the following steps:

[0040] Based on embodiment 2, further shorten the time of vacuum drying for the first time, concrete steps are as follows:

[0041] The unassembled positive and negative plates were vacuum dried for the first time, and the water surface content of the positive and negative plates was detected. The temperature of the first vacuum drying was 180°C, and the vacuum degree of the first vacuum drying was - 0.100mpa;

[0042] Assemble the square cell in the order of the positive electrode sheet, the separator, and the negative electrode sheet in sequence. After the liquid is injected, the cell is vacuum-dried for the second time. The temperature of the first vacuum drying is 84.7°C. The vacuum degree of vacuum drying is -0.084mpa.

[0043] The second vacuum drying is divided into two stages, a stage constant vacuum drying, and a vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com