Angle-adjustable energy-saving manger board

A wave-deflector and angle-adjusting technology, which is applied to ship components, ships, transportation and packaging, etc., can solve the problems of increasing air pressure resistance and increasing navigation energy loss, etc., to reduce pressure resistance and reduce wind area, the effect of reducing the vacuum area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

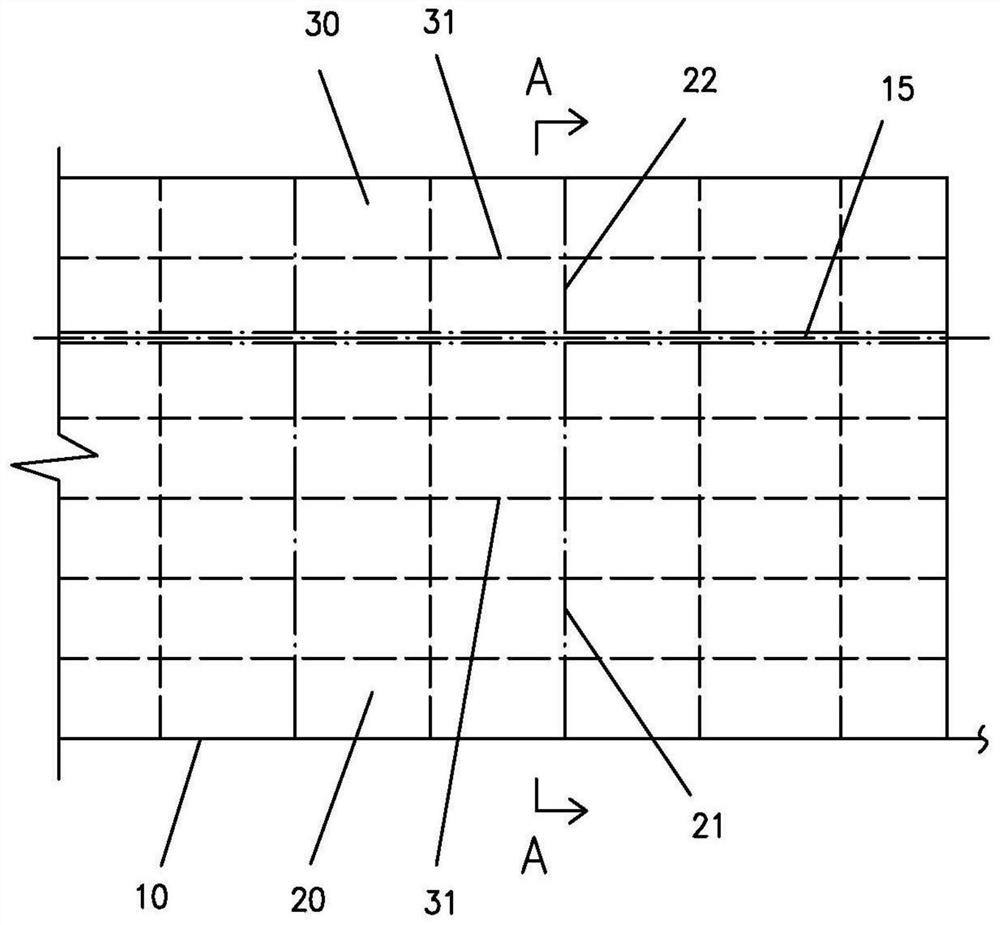

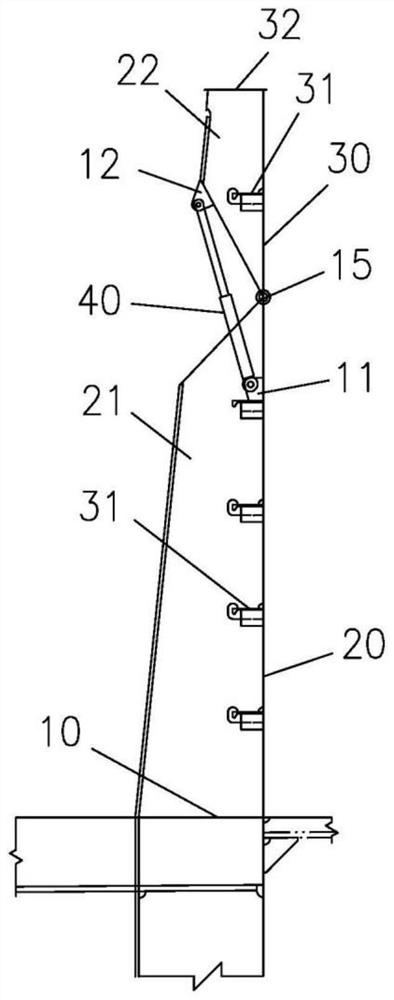

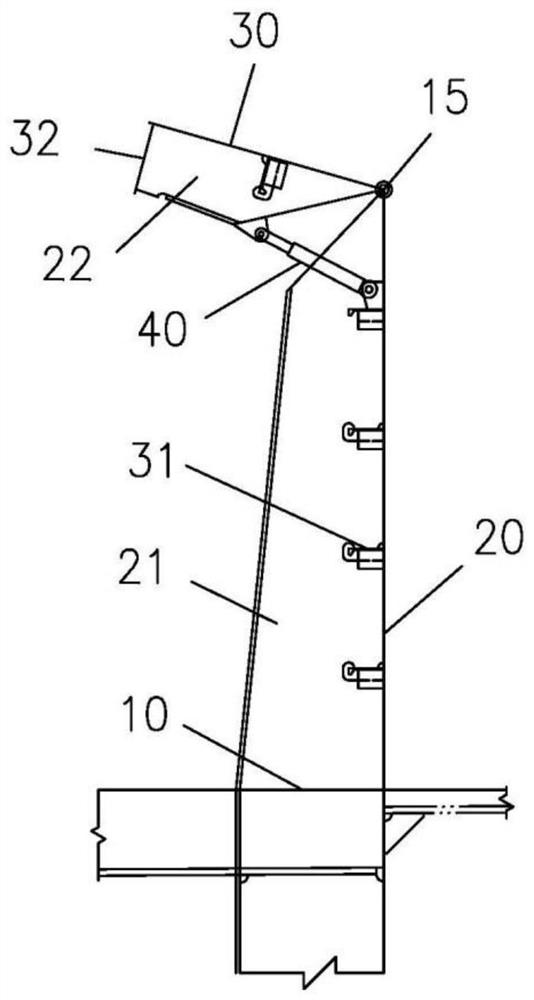

[0020] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0021] Such as figure 1 with figure 2 As shown, an angle-adjustable energy-saving wave breaker includes a lower wall plate 20 fixed on the deck 10 , and an upper wall plate 30 is hinged to the upper end of the lower wall plate 20 . Connect by hinge 15 between upper wall plate and lower wall plate.

[0022] The front end face of the lower wall plate is the end face towards the bow, and the rear end face of the lower wall plate is the end face towards the stern.

[0023] Both the front end surface of the upper wall plate 30 and the front end surface of the lower wall plate 20 are plane. The lower wall panel 20 is perpendicular to the deck 10 .

[0024] The rear end surface of the lower wall plate 20 is fixed with a first reinforcing stringer 21 , and the connection between the first reinforcing stringer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com