A kind of fire-resistant environmental protection curtain wall and preparation method thereof

An environmental protection and curtain wall technology, applied in the field of building materials, can solve problems such as hindering popularization and application, poor mechanical strength and flame retardant performance of starch-based foam materials, and achieve the effects of low price, reduced heat release rate, and reduced CO generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

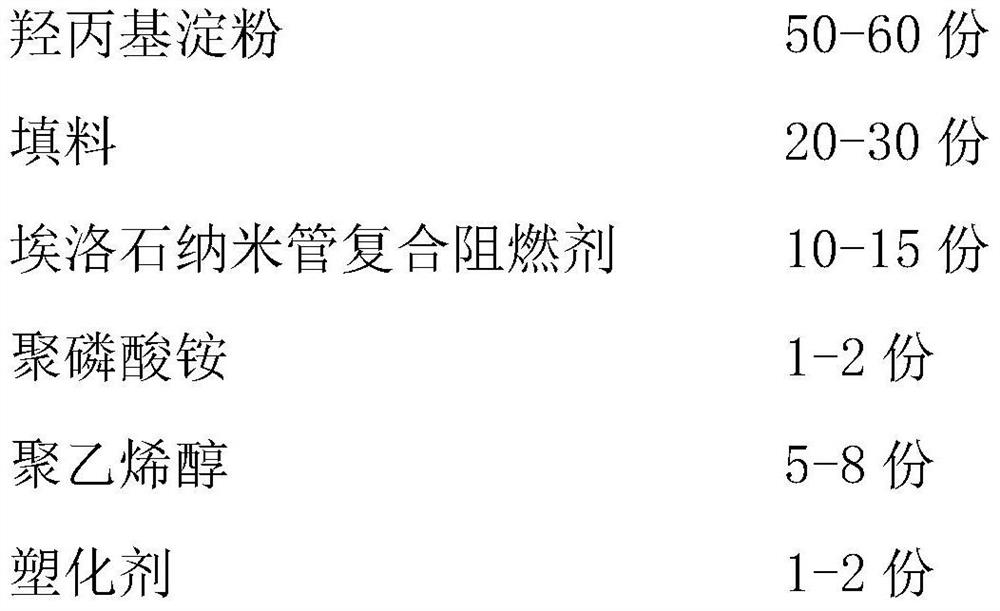

[0025] A fire-resistant and environmentally friendly curtain wall is prepared from raw materials with the following weights:

[0026] 55g of hydroxypropyl starch, 20g of expanded perlite, 10g of halloysite nanotube composite flame retardant, 1g of ammonium polyphosphate, 6g of polyvinyl alcohol, 0.75g of N,N-dihydroxyethyl formamide, 0.25g of sorbitol, Citric acid 0.25g, sodium bicarbonate 0.25g, talcum powder 0.25g, microcrystalline paraffin 0.25g, water 140g.

[0027] Wherein, the preparation method of halloysite nanotube composite flame retardant is as follows:

[0028] Mix 9mL vinyltrimethoxysilane, 200mL methanol, and 12mL hydrochloric acid evenly, seal it, stir at room temperature for 20 days, then filter, wash the solid with methanol, dissolve it in 50mL tetrahydrofuran, add 20g halloysite nanotubes, and slowly drop Methanol, make POSS grow on halloysite nanotubes, let it stand for 1h after dropping, filter and dry the solid to obtain the intermediate, take 20g of the ...

Embodiment 2

[0032] A fire-resistant and environmentally friendly curtain wall is prepared from raw materials with the following weights:

[0033] 60g of hydroxypropyl starch, 20g of expanded perlite, 12g of halloysite nanotube composite flame retardant, 1g of ammonium polyphosphate, 5g of polyvinyl alcohol, 0.75g of N,N-dihydroxyethyl formamide, 0.25g of sorbitol, Citric acid 0.25g, sodium bicarbonate 0.25g, talcum powder 0.25g, microcrystalline paraffin 0.25g, water 120g.

[0034] Wherein, the preparation method of halloysite nanotube composite flame retardant is as follows:

[0035] Mix 9mL vinyltrimethoxysilane, 200mL methanol, and 12mL hydrochloric acid evenly, seal it, stir at room temperature for 25 days, then filter, wash the solid with methanol, dissolve it in 50mL tetrahydrofuran, add 20g halloysite nanotubes, and slowly drop Methanol, make POSS grow on the halloysite nanotubes, let it stand for 1h after dropping, and obtain the intermediate, take 20g of the intermediate, 100mL ...

Embodiment 3

[0039] A fire-resistant and environmentally friendly curtain wall is prepared from raw materials with the following weights:

[0040] 50g of hydroxypropyl starch, 30g of expanded perlite, 10g of halloysite nanotube composite flame retardant, 2g of ammonium polyphosphate, 5g of polyvinyl alcohol, 0.75g of N,N-dihydroxyethyl formamide, 0.25g of sorbitol, Citric acid 0.25g, sodium bicarbonate 0.25g, talcum powder 0.25g, microcrystalline paraffin 0.25g, water 120g.

[0041] Wherein, the preparation method of halloysite nanotube composite flame retardant is as follows:

[0042]Mix 9mL vinyltrimethoxysilane, 200mL methanol, and 12mL hydrochloric acid evenly, seal it, stir at room temperature for 25 days, then filter, wash the solid with methanol, dissolve it in 50mL tetrahydrofuran, add 20g halloysite nanotubes, and slowly drop Crystallize methanol, grow POSS on halloysite nanotubes, let it stand for 1 hour after dropping to obtain the intermediate, take 20g of the intermediate, 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com