Multi-layer low-altitude anti-sideslip supporting cushion box and using method thereof

A technology of supporting box and cushion box, applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems affecting the prestressing and tensioning construction of the ends of continuous steel arch bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

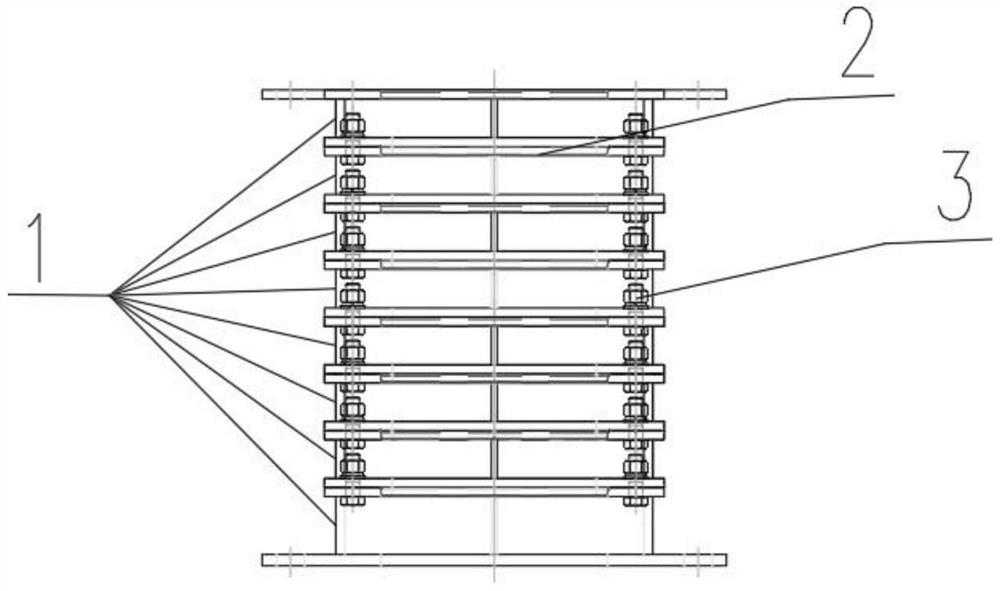

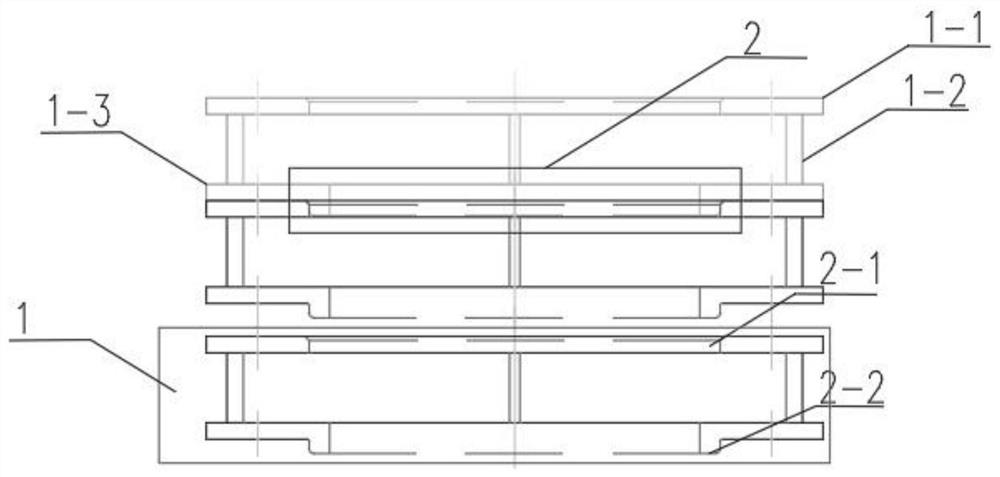

[0019] Embodiment 1: as Figure 1~Figure 2 As shown, a multi-layer low-altitude anti-skid support mat box includes a support mat box 1, a plurality of support mat boxes 1 are stacked, and two adjacent support mat boxes 1 are detachably connected.

[0020] Preferably, the above-mentioned support cushion box 1 includes a panel 1-1, a partition 1-2 and a bottom plate 1-3, and the panel 1-1 and the bottom plate 1-3 pass through a plurality of vertical (3) partitions 1- 2 Fixed connection, the structure has high rigidity and strength, good support stability, and the hollow structure is light in weight, which is more conducive to bolt connection and reduces the weight of the cushion box itself, which is convenient for construction operations in limited site space. At the same time, it needs to cooperate with the top beam oil top Quantitative jacking (lowering) cross switching operations are performed to lower the adjacent span box girder to the design elevation.

[0021] Preferably...

Embodiment 2

[0026] Embodiment 2: A method of using a multi-layer low-altitude anti-sideslip support pad box, the method is: through the precision-rolled rebar reserved in the pad stone and the reserved hole in the lower part of the support pad box 1, anchor the support pad The box is consolidated with the pier pad stone; the support pad box 1 is superimposed through the occlusal and close fit of the anti-skid structure, and at the same time, the layers of the support pad box 1 are fastened by bolts 3 to realize the addition and subtraction of the support stroke of the low-altitude anti-side slip pad box; The reserved hole in the upper part of the cushion box 1 is connected with the embedded plate of the bottom support of the supporting box girder through bolts, so as to realize the consolidation of the supporting cushion box and the storage beam body, and solve the problem that the cast-in-place steel arch structure is not completed, which affects the ballastless of simply supported box gir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com