A pipe jacking machine for water conservancy engineering

A technology for water conservancy projects and pipe jacking machines, which is used in vertical shaft equipment, shaft lining, transportation and packaging, etc., can solve the problems of inability to adapt to the installation height of pipelines, manual landfilling, and time-consuming operation, and achieves stable structure and convenient pick and place. , the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

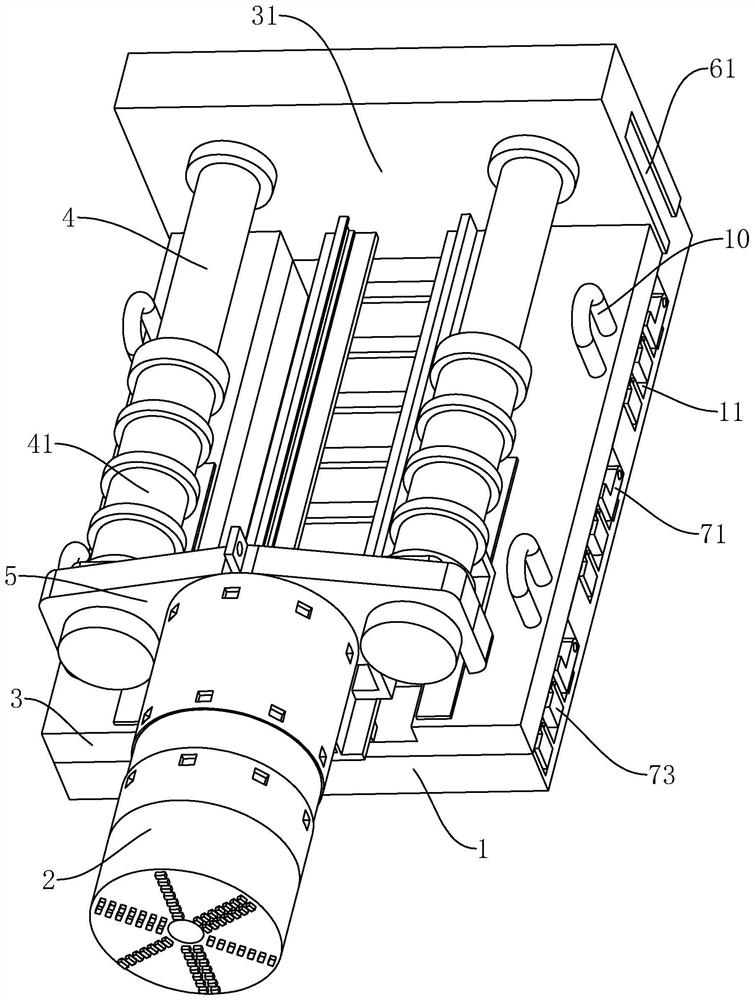

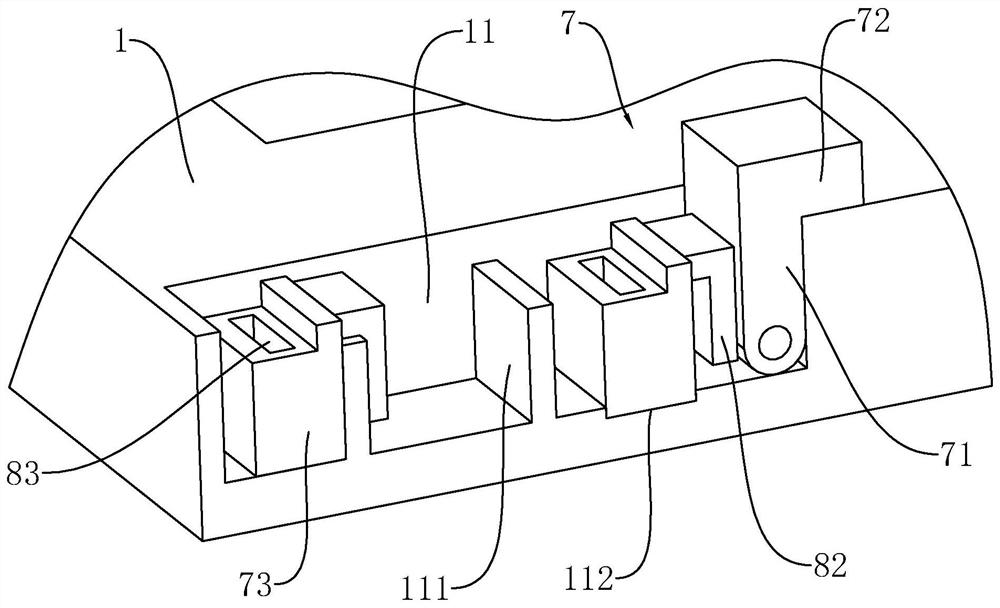

[0035] like figure 1 As shown, it is a pipe jacking machine for hydraulic engineering disclosed by the present invention, which includes a base 1 and a pipe jacking body 2, the upper part of the base 1 is connected with an adjustment seat 3, and the pipe jacking body 2 is installed on the adjustment seat 3; the adjustment seat 3 A support plate 31 is fixed on one side of the support plate 31, and two relative drive cylinders 4 are fixed on the support plate 31, and the drive cylinder 4 extends along the side away from the support plate 31. The push rod 41 inserted on the side wall of the push plate 5 is fixed on the drive cylinder 4 on the plate 5 , and the push plate 5 abuts against the pipe jacking body 2 .

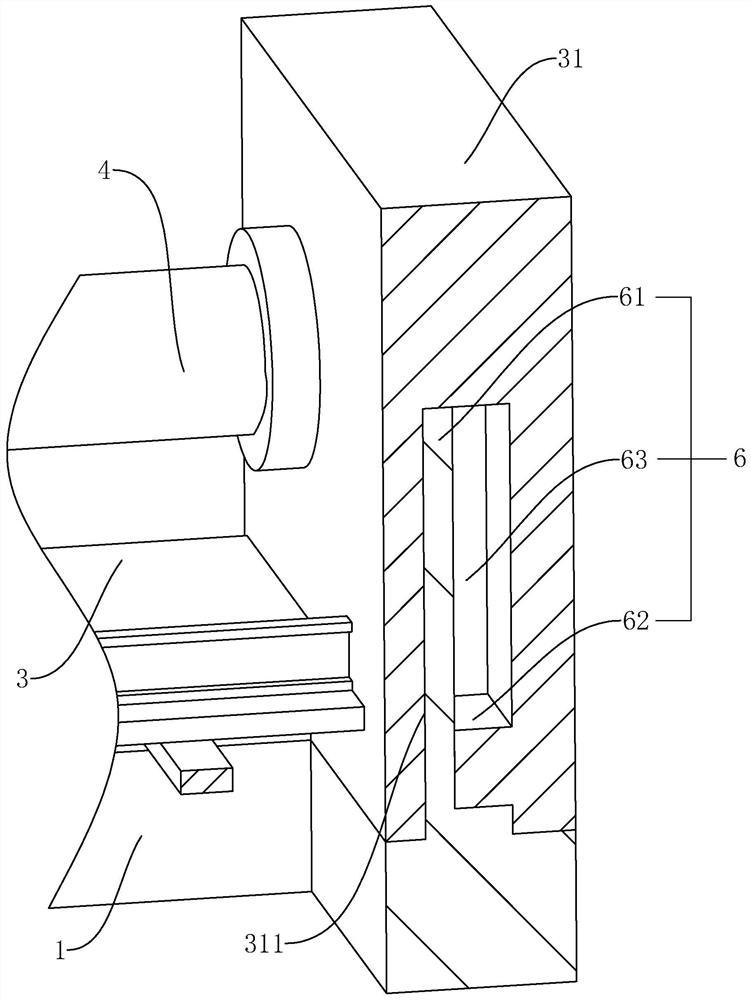

[0036] like figure 1 , 2 As shown, the support plate 31 is movably connected to the base 1 through the connection structure 6, so that the adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com