Wall surface dry construction structure and construction method thereof

A dry method and wood panel technology, applied in the field of architectural decoration, can solve the problems of long cement mortar paving period, complex cement mortar process, and large pollution on the construction site, and achieve the effects of shortening the construction period, reducing processing costs, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is attached Figure 1-6 The application is described in further detail.

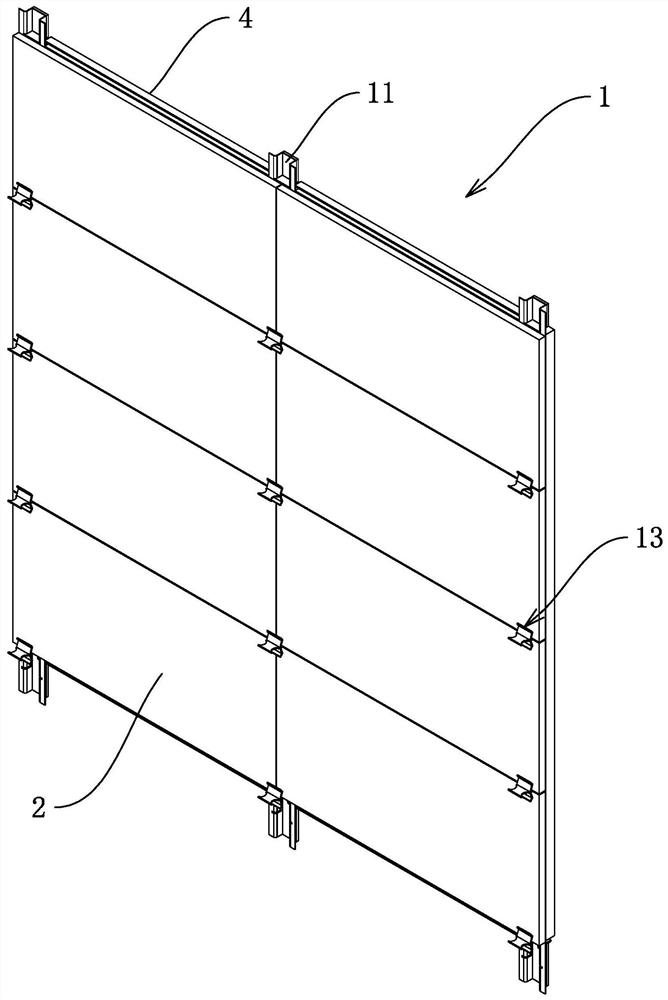

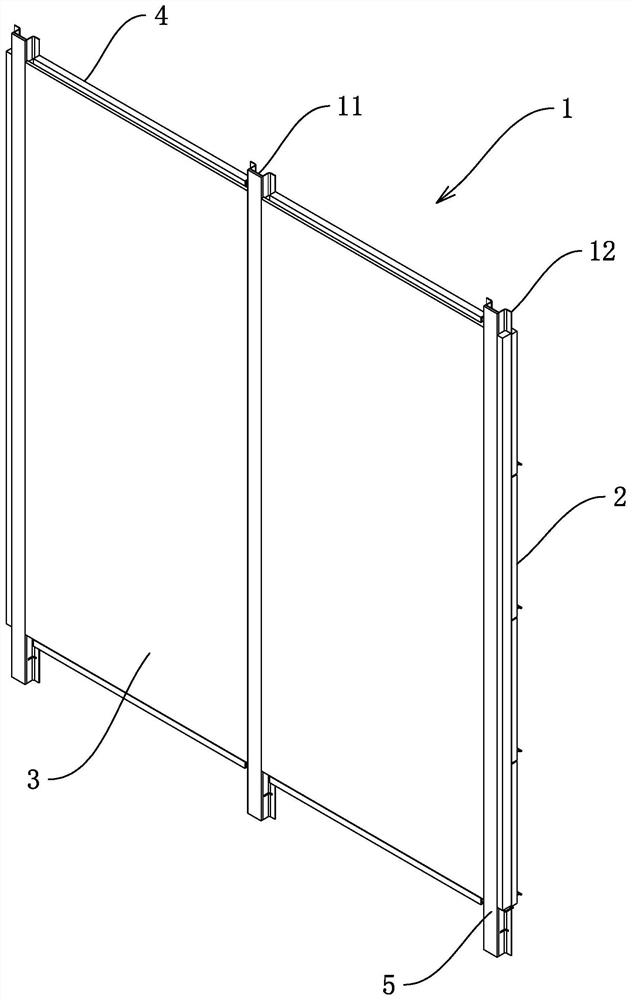

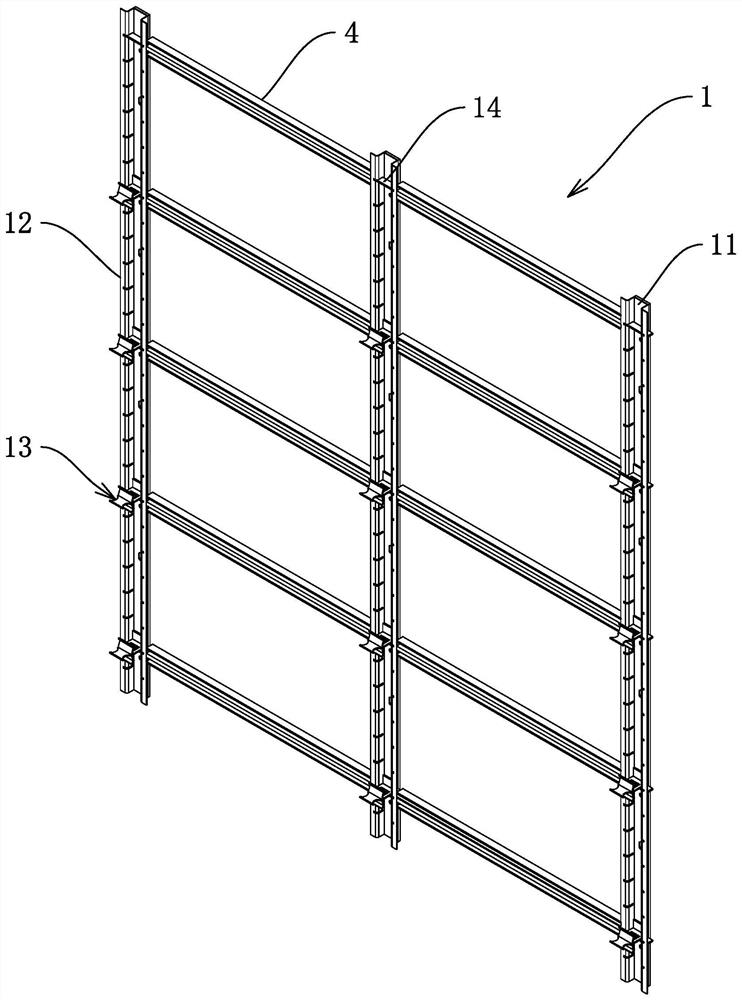

[0046] The embodiment of the application discloses a wall surface dry construction structure. Such as figure 1 with figure 2 As shown, the wall surface dry construction structure includes the base frame body 1 fixed on the wall surface and the tiles 2 installed on the base frame body 1, and the space between the tiles 2 and the wall surface is filled with foam glue, and the foam glue solidifies Finally, the foamed glue layer 3 is formed, and the foamed glue layer 3 is fixed to the wall surface, the basic frame body 1 and the ceramic tile 2. The basic frame body 1 cooperates with the foamed rubber layer 3 to stabilize and fix the tiles 2. Since the foamed rubber layer 3 has the function of thermal insulation and sound insulation, the thermal insulation and sound insulation effect of the wall can be improved. At the same time, dry construction has the characteristics of high effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com