Integral mounting structure and method for platform in tower

A technology of installation structure and inner platform, applied in the directions of installing/supporting wind turbine configuration, wind turbine, climate sustainability, etc., can solve the problems of heavy workload of on-site workers, evaluating construction cost, increasing process cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

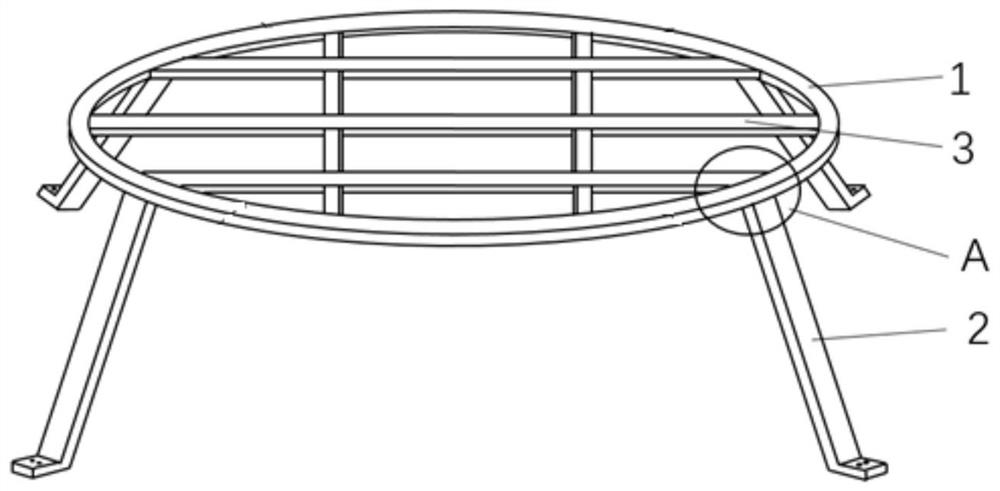

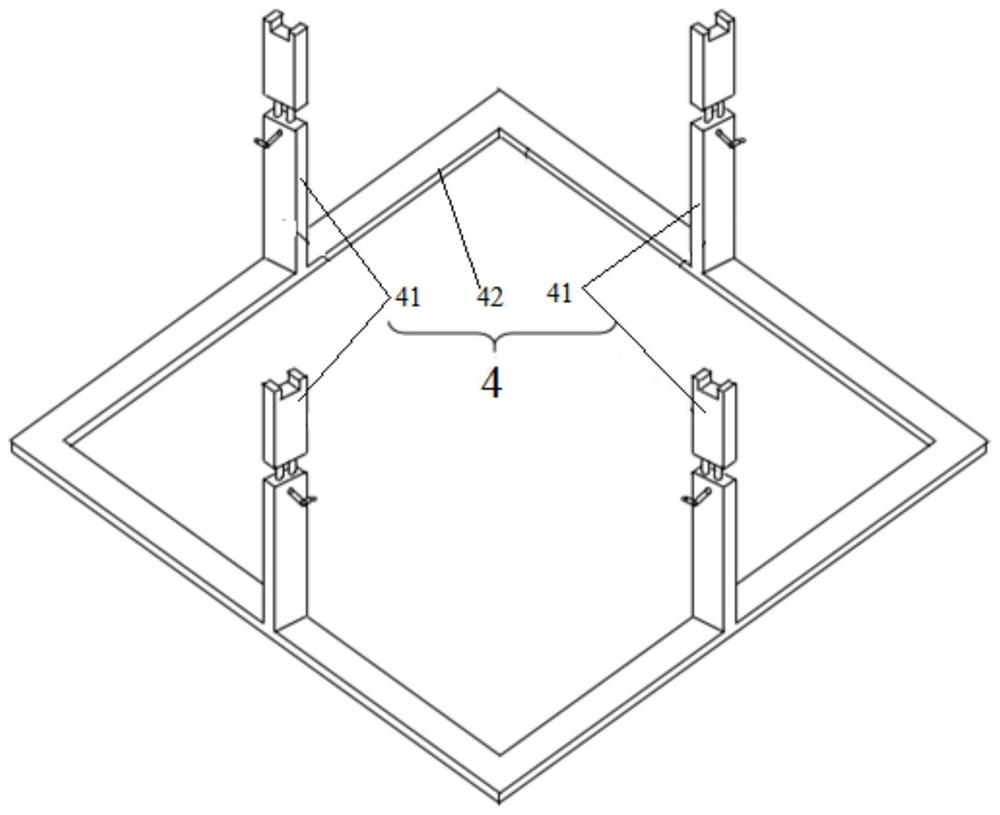

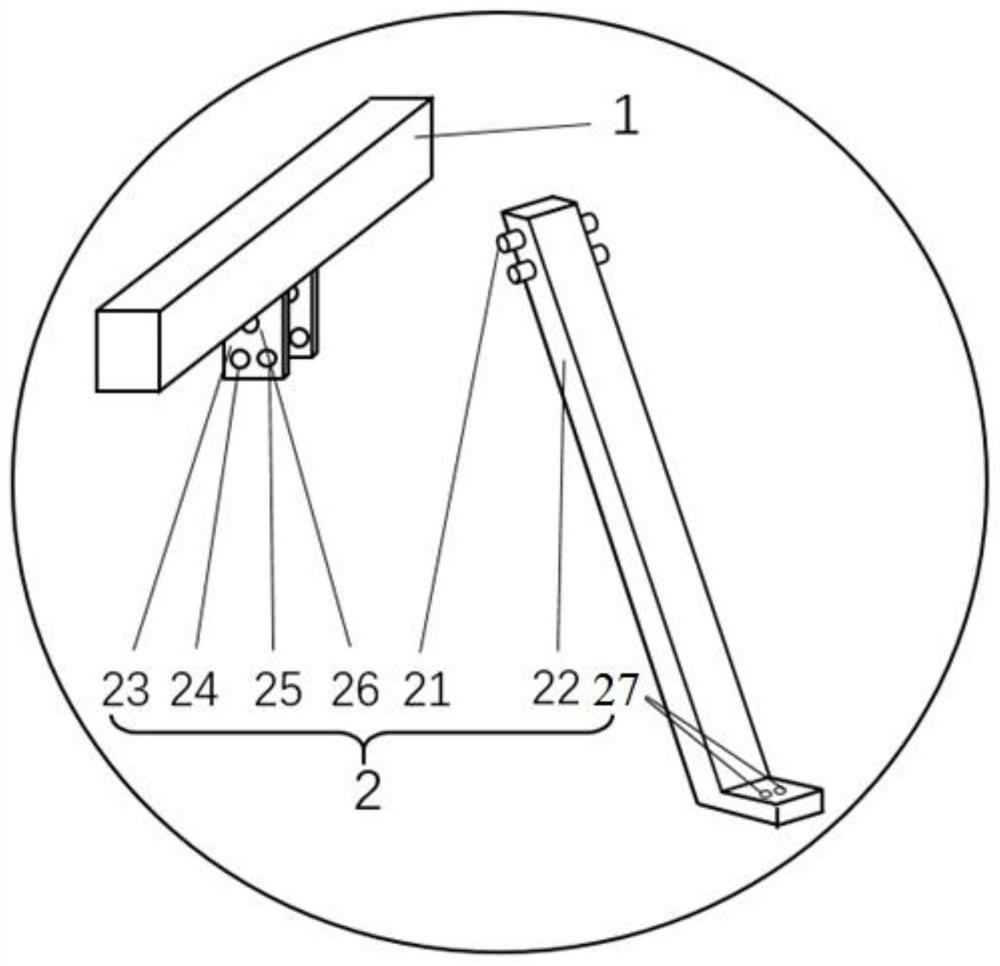

[0034] refer to figure 1 and figure 2 , an integral installation structure of the inner platform of a tower, comprising an inner platform circular frame 1, a support leg structure 2, an inner platform truss 3 and an integral installation base 4. Wherein, supporting leg structure 2 comprises supporting leg 22 and connecting plate 23, and the upper end of supporting leg 22 is provided with stud 21, and the lower end of supporting leg 22 is provided with bolt hole 27, and connecting plate 23 is arranged on the bottom surface of inner platform circular frame 1, connects A first socket 24, a second socket 25 and a third socket 26 are provided on the plate 23, the first socket 24, the second socket 25 and the third socket 26 are distributed in a triangle, and the studs 21 are inserted into the socket 24 In, the support leg 22 is connected with the circular frame 1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com