Immersed heat dissipation system

A heat dissipation system and immersion technology, applied in the fields of instruments, computing, electrical digital data processing, etc., can solve the problems of large power consumption for cooling liquid cooling and heat exchange, unfavorable energy saving, high heat generation, reduce power consumption, and benefit Popularization and promotion, the effect of lowering the selling price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

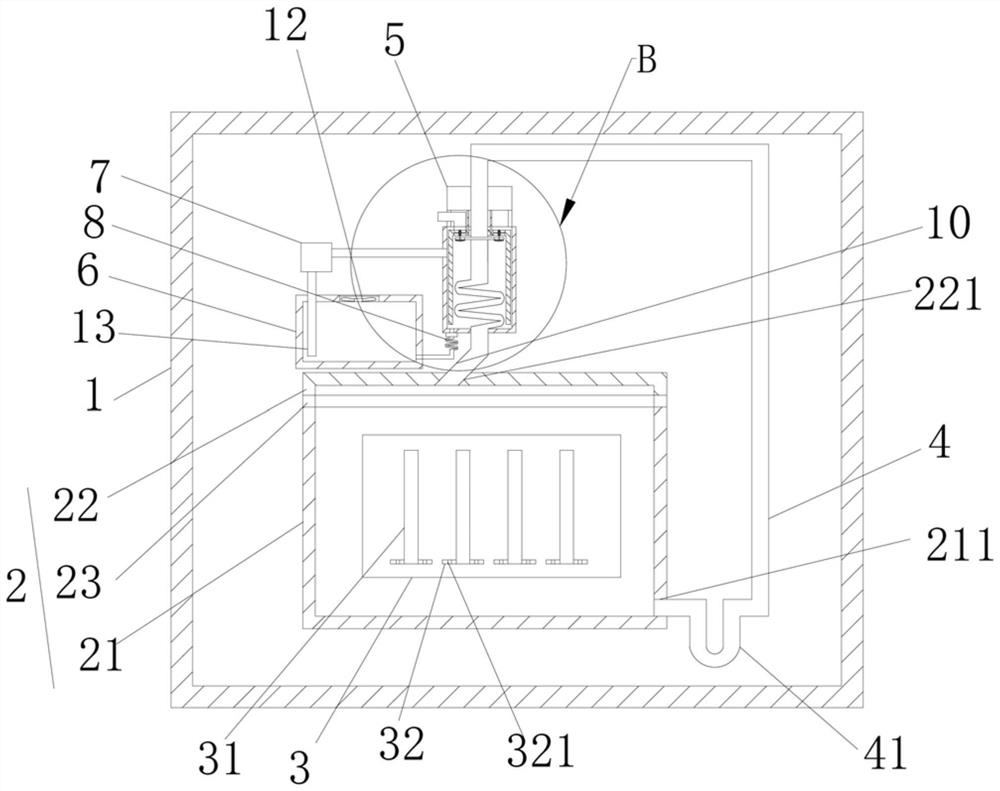

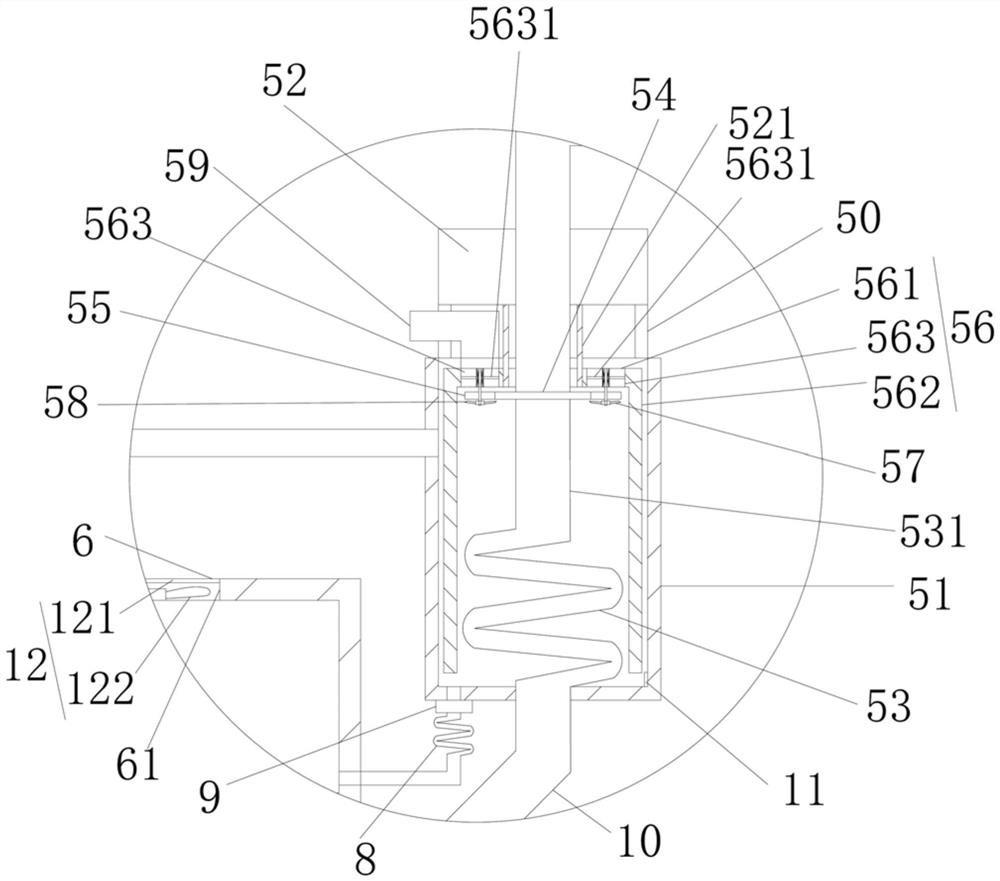

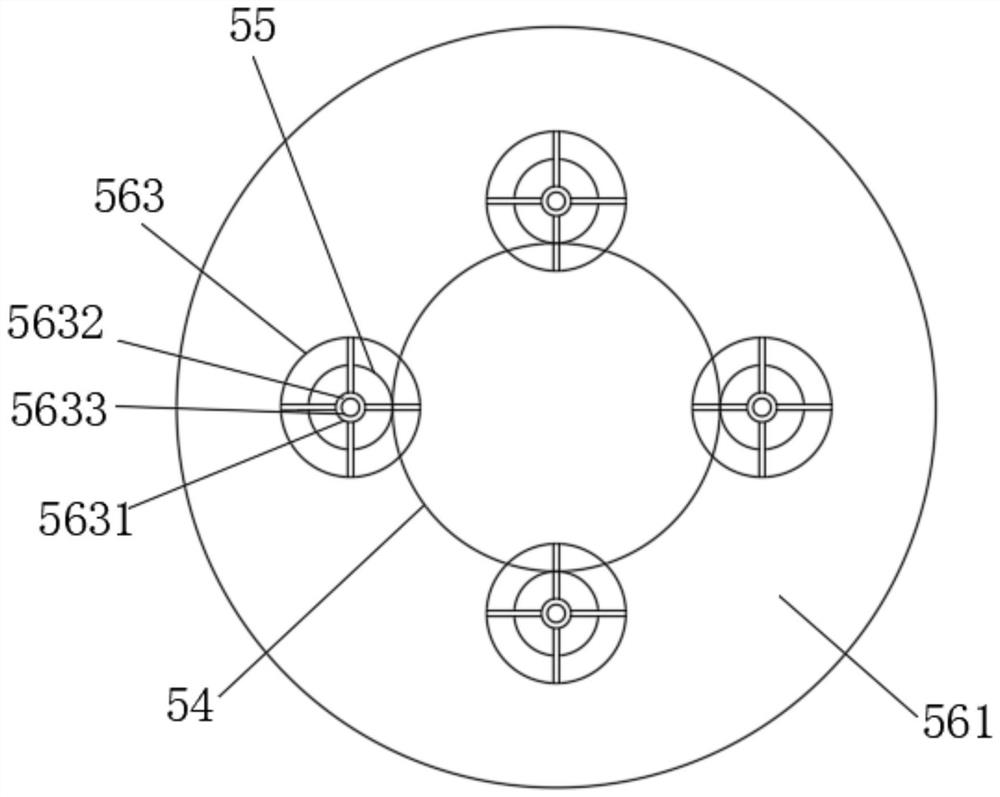

[0020] As shown in the drawings, the submerged heat dissipation system described in this embodiment includes a main box 1, and a cooling box 2 and a cooling liquid cooling device 5 are arranged in the main box 1, and the side inner wall of the cooling box 2 A main board 3 is fixed on the main board 3, and a plurality of accessories 31 spaced apart from each other are vertically installed on the main board 3. A buffer plate body 32 is arranged on the bottom side of the accessories 31, and a flow guide hole 321 is arranged on the buffer plate body 32. The cooling box The body 2 is provided with a liquid outlet 211 and a liquid inlet 221, and the liquid outlet 211 is equipped with a liquid outlet pipe 4; the cooling liquid cooling device 5 includes a cooling housing 51, a rotating drive motor 52, and a cooling housing 51. The first helical duct 53, the planetary gear set (not marked in the figure) and the stirring frame 56, wherein the first helical duct 53 and the cooling shell 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com