Baked fragrant tea leaves, preparation method thereof and tea extract liquor prepared from baked fragrant tea leaves

A production method and tea technology, which are applied in the directions of pre-extraction tea treatment, climate change adaptation, etc., can solve problems such as insufficient tea aroma and flavor, and achieve the effects of strong roasting aroma, mellow and sweet taste, and prolonging storage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

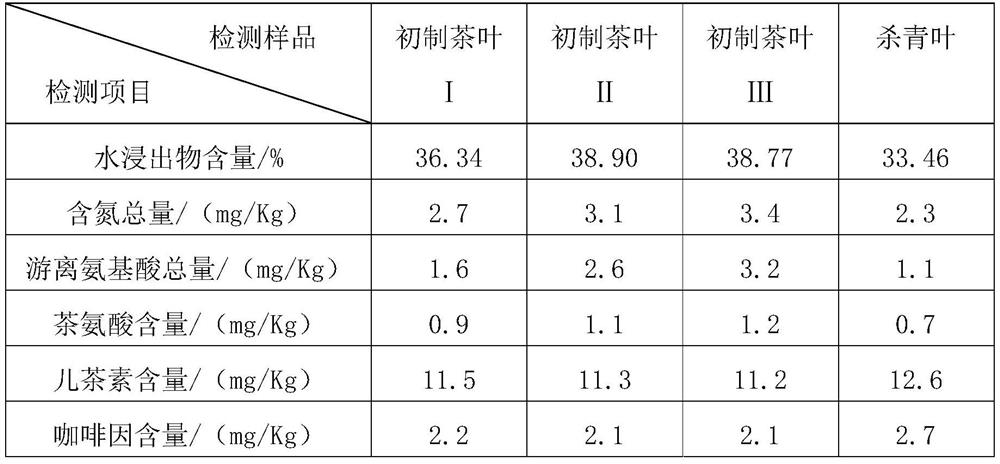

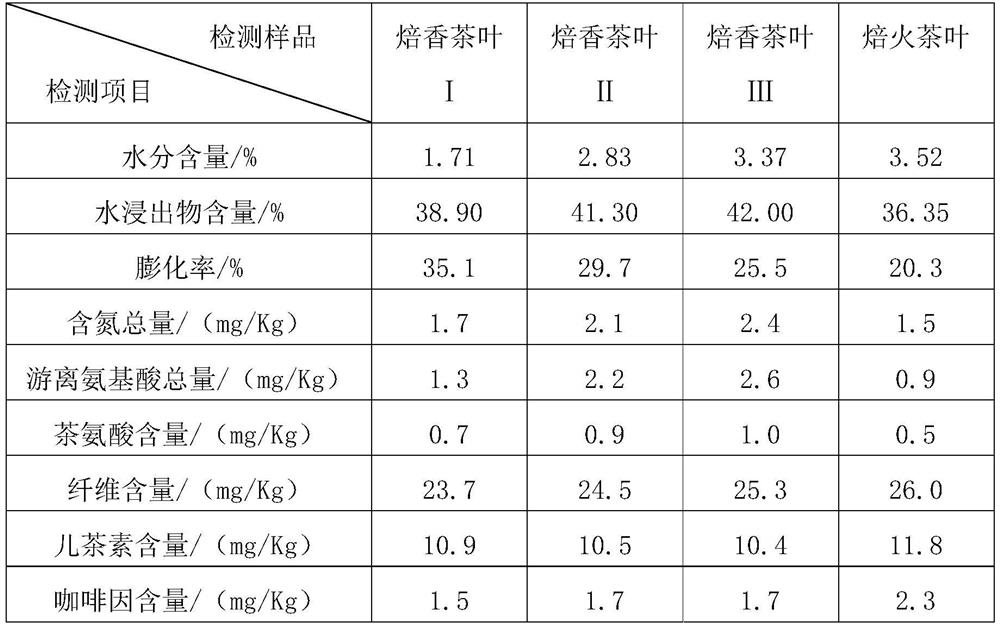

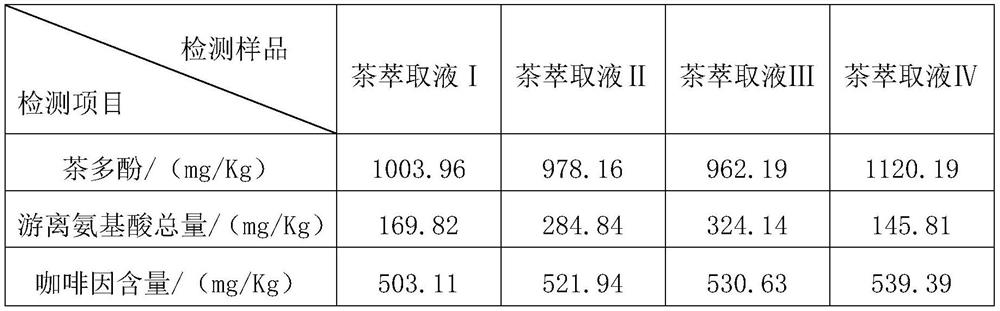

Embodiment 1

[0022] Including the following production processes:

[0023] S1) pluck tea greens (i.e. picking greens), and carry out withering and finishing the tea greens according to traditional crafts, to obtain green leaves;

[0024] S2) heat preservation: place the green leaves statically in an environment with a temperature of 45° C. and a humidity of 30% for 4 hours;

[0025] S3) rolling, drying and refining the tea leaves after heat preservation treatment according to traditional techniques;

[0026] S4) Cutting and sieving process I: Cut and sieve the refined tea leaves into three tea groups with different mesh sizes, namely: tea group I with a particle size of 7 mesh or more, tea group II with a particle size of 7 to 40 mesh, and tea group II with a particle size It is tea group III under 40 mesh;

[0027] S5) Roasting process I: The tea group I is subjected to a roasting treatment with a roasting temperature of 160°C and a roasting time of 8 minutes, so that the moisture conte...

Embodiment 2

[0033] Including the following production processes:

[0034] S1) pluck tea greens (i.e. picking greens), and carry out withering and finishing the tea greens according to traditional crafts, to obtain green leaves;

[0035] S2) heat preservation: place the green leaves statically in an environment with a temperature of 55° C. and a humidity of 25% for 5 hours;

[0036] S3) rolling, drying and refining the tea leaves after heat preservation treatment according to traditional techniques;

[0037] S4) Cutting and sieving process I: Cut and sieve the refined tea leaves into three tea groups with different mesh sizes, namely: tea group I with a particle size of 7 mesh or more, tea group II with a particle size of 7 to 40 mesh, and tea group II with a particle size It is tea group III under 40 mesh;

[0038] S5) Roasting process I: The tea group I is subjected to a roasting treatment with a roasting temperature of 170°C and a roasting time of 10 minutes, so that the moisture cont...

Embodiment 3

[0044] Including the following production processes:

[0045] S1) pluck tea greens (i.e. picking greens), and carry out withering and finishing the tea greens according to traditional crafts, to obtain green leaves;

[0046] S2) heat preservation: place the green leaves statically in an environment with a temperature of 60° C. and a humidity of 35% for 3 hours;

[0047] S3) rolling, drying and refining the tea leaves after heat preservation treatment according to traditional techniques;

[0048] S4) Cutting and sieving process I: Cut and sieve the refined tea leaves into three tea groups with different mesh sizes, namely: tea group I with a particle size of 7 mesh or more, tea group II with a particle size of 7 to 40 mesh, and tea group II with a particle size It is tea group III under 40 mesh;

[0049]S5) Roasting process I: The tea group I is subjected to a roasting treatment with a roasting temperature of 150° C. and a roasting time of 12 minutes, so that the moisture con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com