Oolong tea and baking method thereof

A roasting method, the technology of oolong tea, applied in tea processing before extraction, etc., can solve the problem of lack of charcoal roasting for quality characteristics, achieve the effect of improving quality, improving roasting efficiency, and highlighting the fruity aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

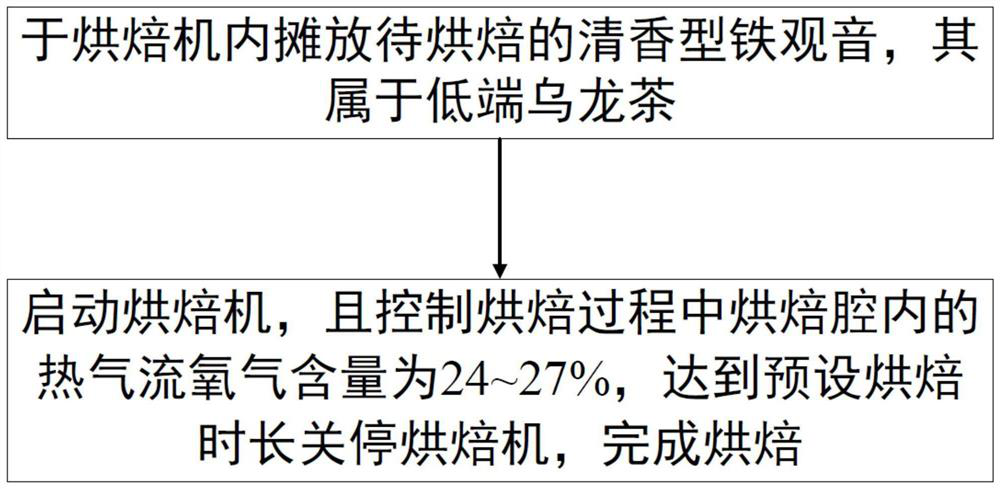

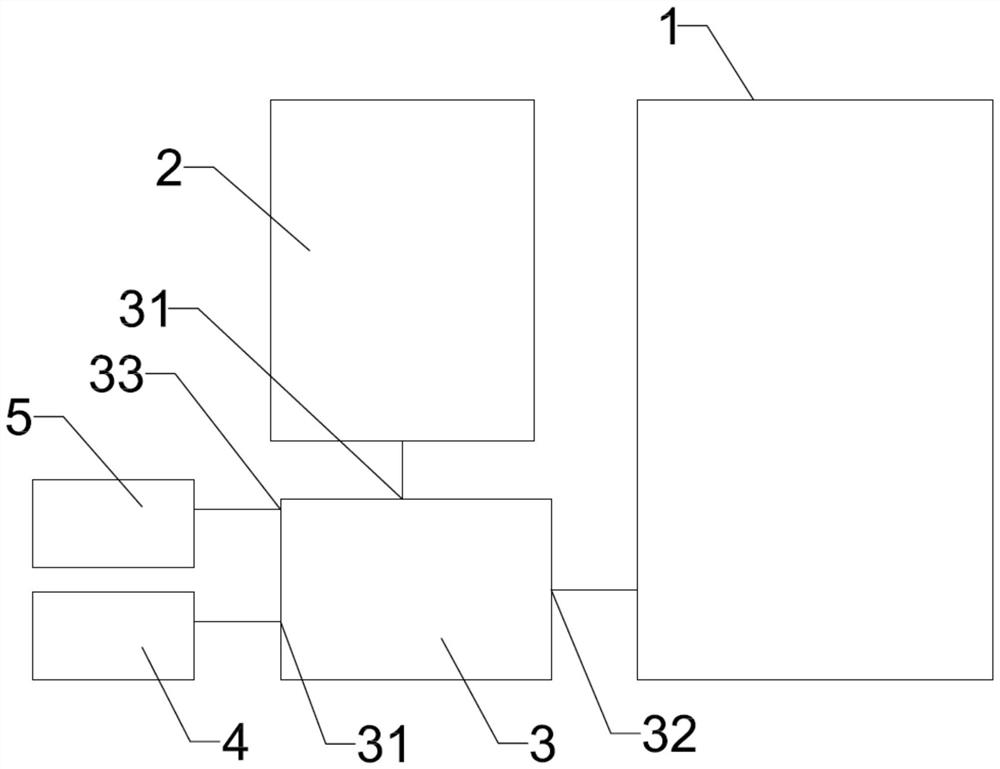

[0030] Please refer to figure 1 , present embodiment provides a kind of baking method of oolong tea, it comprises the following steps:

[0031] (1) Put the Fen-flavored Tieguanyin tea to be baked in the roasting machine, which belongs to low-end oolong tea;

[0032] Specifically, spread the Fen-flavor oolong tea to be baked thickly, with a thickness of about 6-8 cm, and keep a certain gap between the raw oolong teas to allow the hot air to pass through.

[0033] (2) Start the roasting machine, and control the oxygen content of the hot air in the roasting cavity to 24~27% during the roasting process. When the preset roasting time is reached, turn off the roasting machine, complete the roasting, and cool down to obtain Luzhou-flavored oolong tea.

[0034] Specifically, during the baking process, the air pressure in the baking chamber was set at normal pressure, the temperature of the hot air flow was controlled at 130° C., and the baking time was 4 hours. During the roasting p...

Embodiment 2

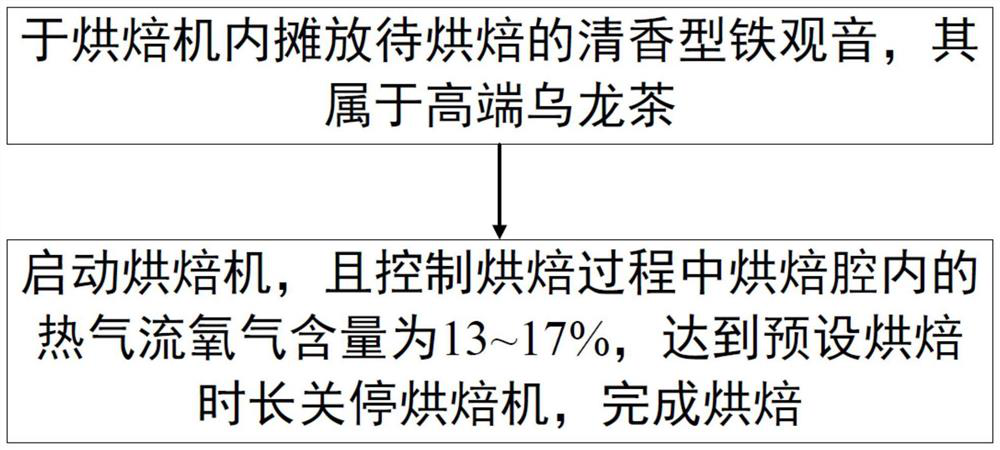

[0036] The present embodiment provides a kind of roasting method of oolong tea, it comprises the following steps:

[0037] (1) Spread the fragrant rock tea to be baked in the roasting machine, which belongs to low-end oolong tea;

[0038] Specifically, spread the Fen-flavor oolong tea to be baked thickly, with a thickness of about 6-8 cm, and keep a certain gap between the raw oolong teas to allow the hot air to pass through.

[0039] (2) Start the roasting machine, and control the oxygen content of the hot air in the roasting cavity to 25-28% during the roasting process. When the preset roasting time is reached, turn off the roasting machine, complete the roasting, and cool down to obtain Luzhou-flavored oolong tea.

[0040] Specifically, during the baking process, the air pressure in the baking chamber was set at normal pressure, the temperature of the hot air flow was controlled at 140° C., and the baking time was 8 hours. During the roasting process, the hot air flow in t...

Embodiment 3

[0042] The difference between this embodiment and embodiment 2 is that the hot gas flow is a mixed gas of oxygen and nitrogen, wherein the oxygen content is controlled at 25-28%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com