A box packing machine

A case packing machine and rack technology, applied in the field of case packing machines, can solve the problems of increasing the number of workers, low packaging efficiency, high labor intensity, etc., and achieve simple and fast adjustment, convenient switching of specifications, and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

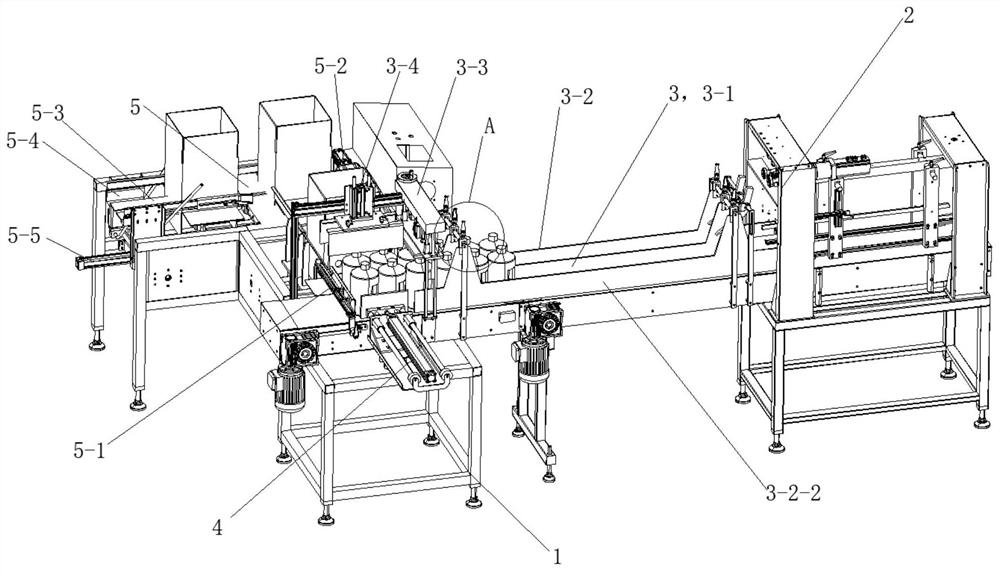

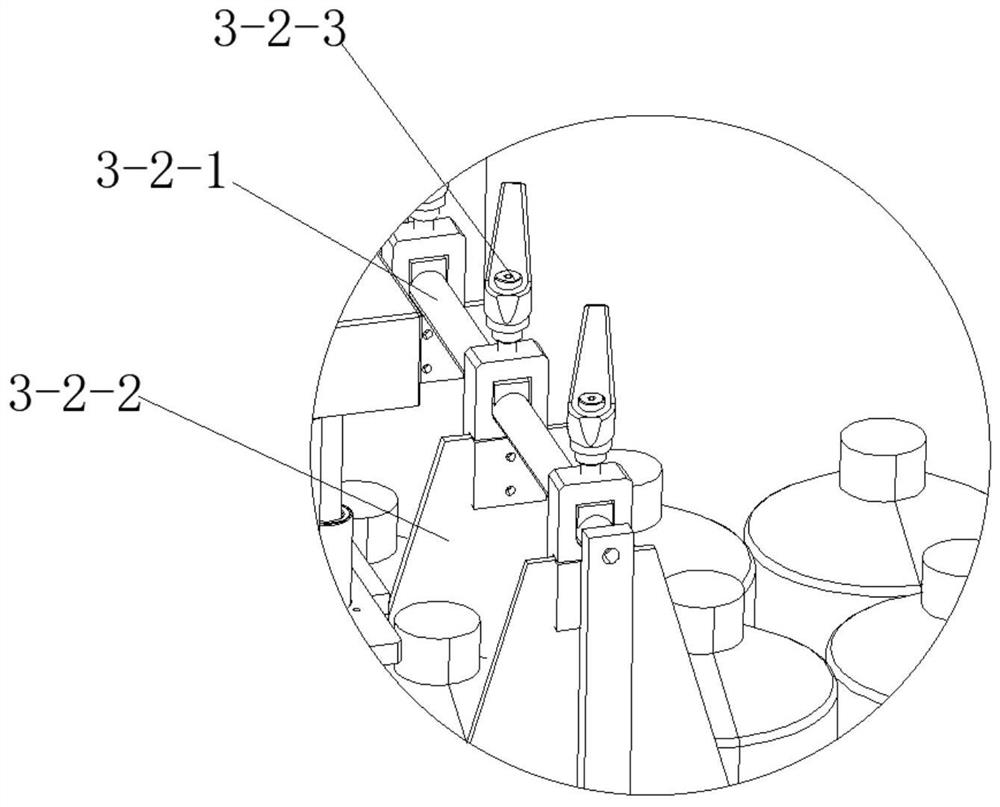

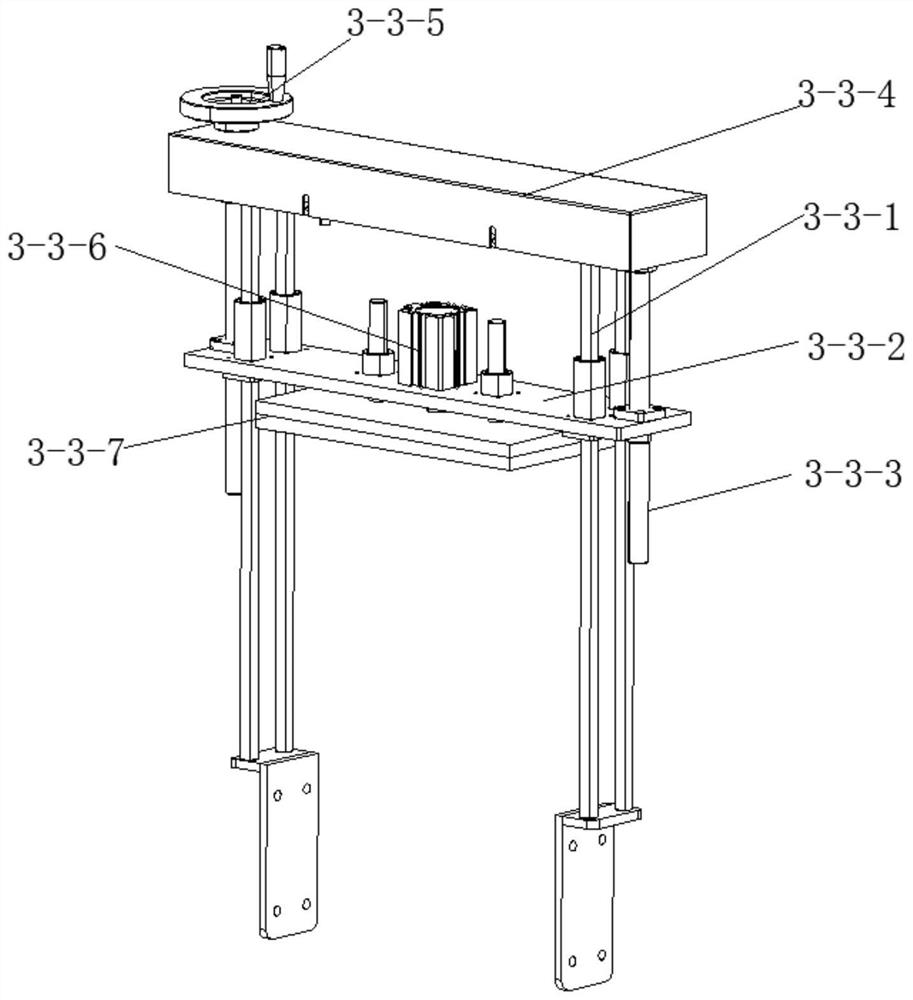

[0050] like Figure 1 to Figure 10 The shown case packing machine includes a frame 1 , and a lane separation device 2 , a bottle conveying device 3 , a bottle pushing device 4 and a box folding device 5 , which are arranged on the frame 1 . The lane separating device 2 communicates with the bottle pushing device 4 through the bottle conveying device 3 , and the bottle pushing device 4 is suitable for pushing the bottles to be packed to the folding box device 5 . The bellows device 5 includes a first bellows assembly and a second bellows assembly. The lane dividing device 2 divides the bottles to be packed into multiple lanes, and the bottle conveying device 3 transports the bottles to the bottle pushing device 4 according to the quantity specified by the packing specification. The box with the top sealed is put on the bottle, and the automatic folding of the bottom short side and the long side of the carton on the bottle is completed by the first folding box component and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com