System and method for deep purification of coke oven gas to produce hydrogen

A coke oven gas and deep purification technology, which is applied in combustible gas purification, chemical instruments and methods, combustible gas purification/transformation, etc., can solve problems such as affecting the stable operation of the system, increasing operating costs, and compressor blockage, so as to improve recovery The effect of efficiency and utilization, investment reduction, and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

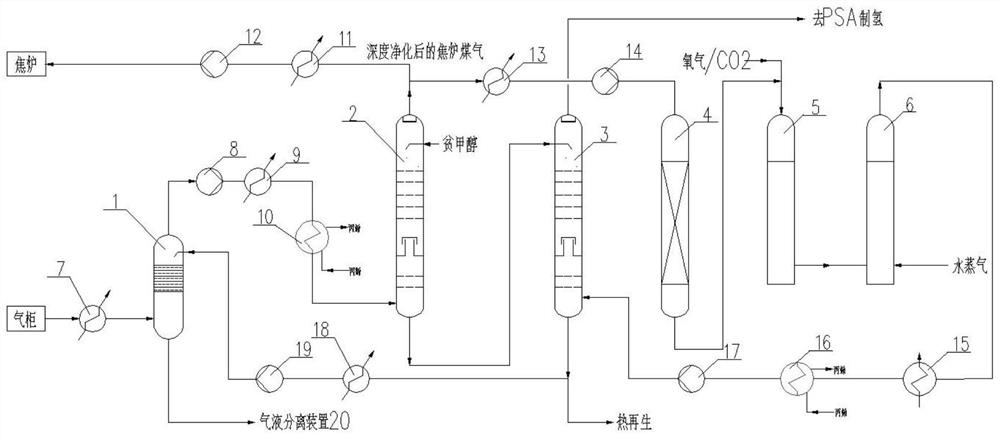

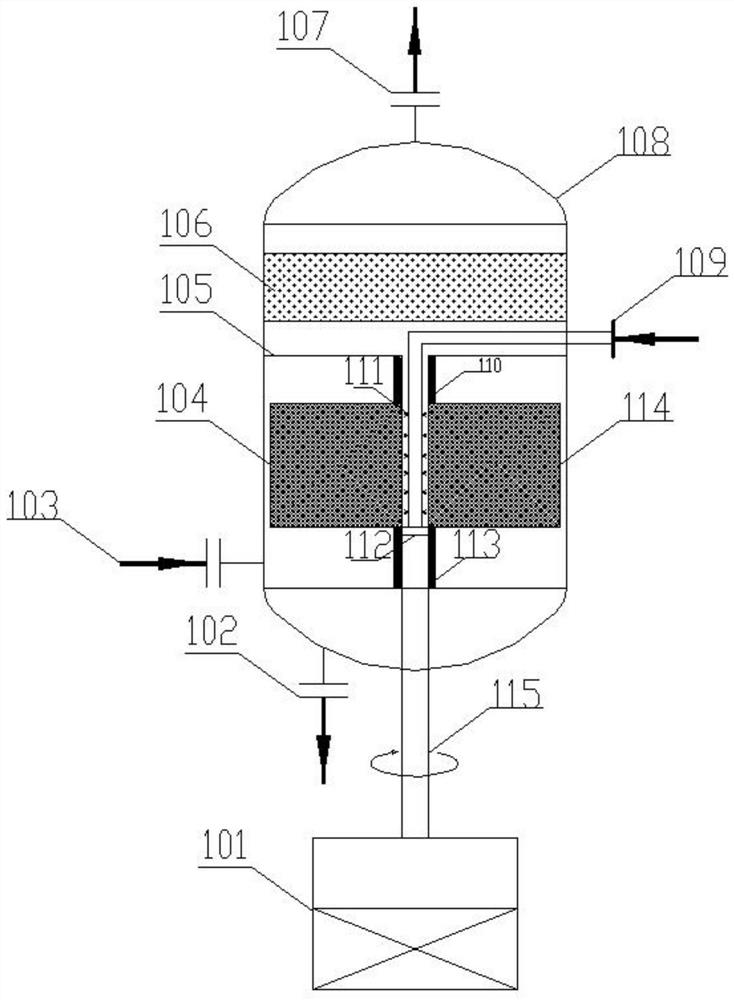

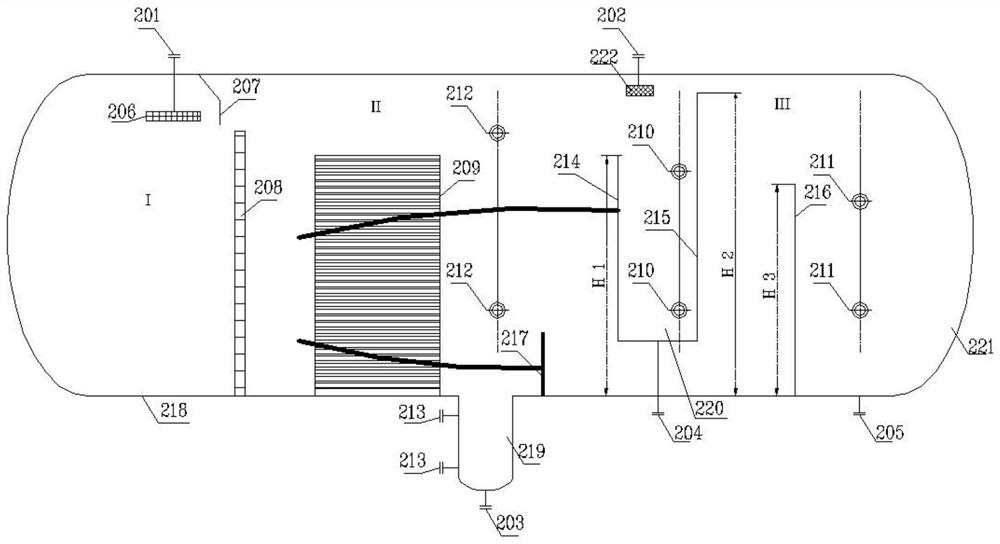

[0035] like figure 1 As shown, the embodiment of the present invention provides a system for deep purification of coke oven gas for hydrogen production, which includes a prewash tower 1, a desulfurization tower 2, a decarburization tower 3, a fine desulfurization tower 4, a reformer 5 and a shift furnace 6, The prewash tower 1 is a supergravity rotating device, wherein: the gas cabinet is connected to the gas phase inlet 103 at the bottom of the prewash tower 1 through the first heat exchanger 7, and the liquid phase outlet 102 at the bottom of the prewash tower 1 is connected to the gas-liquid separation device. 20 is connected, the gas outlet 107 at the top of the prewash tower 1 is connected with the air inlet at the bottom of the desulfurization tower 2 through the first compressor 8, the second heat exchanger 9 and the third heat exchanger ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap