Precise instrument electroplating method

A technology of precision instruments and electroplating baths, which can be used in plating baths, electrolysis processes, electrolysis components, etc., and can solve the problems of floating and high loss of electroplating solution capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

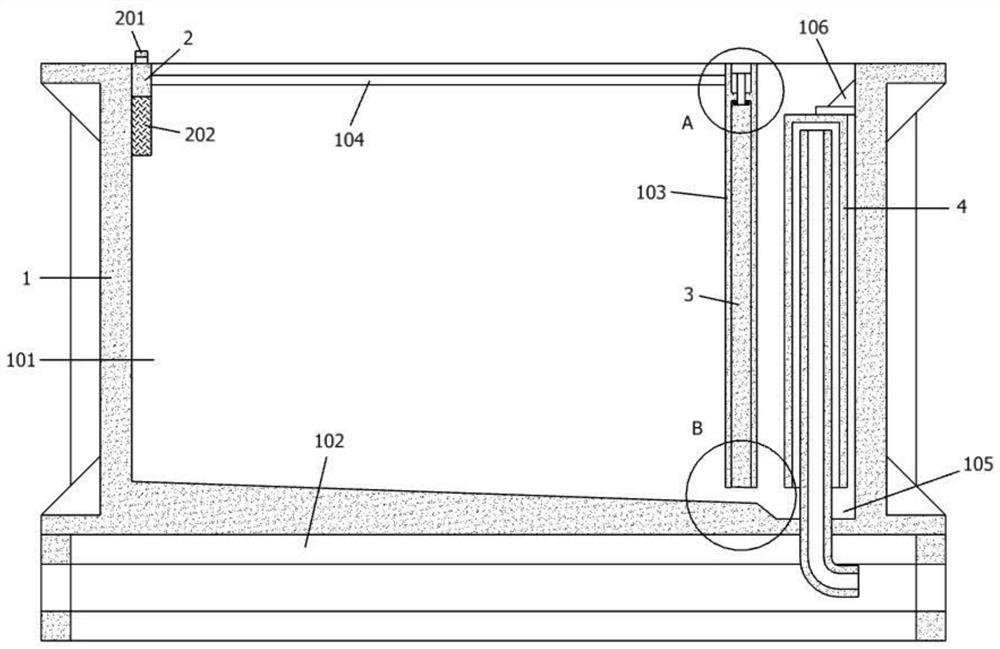

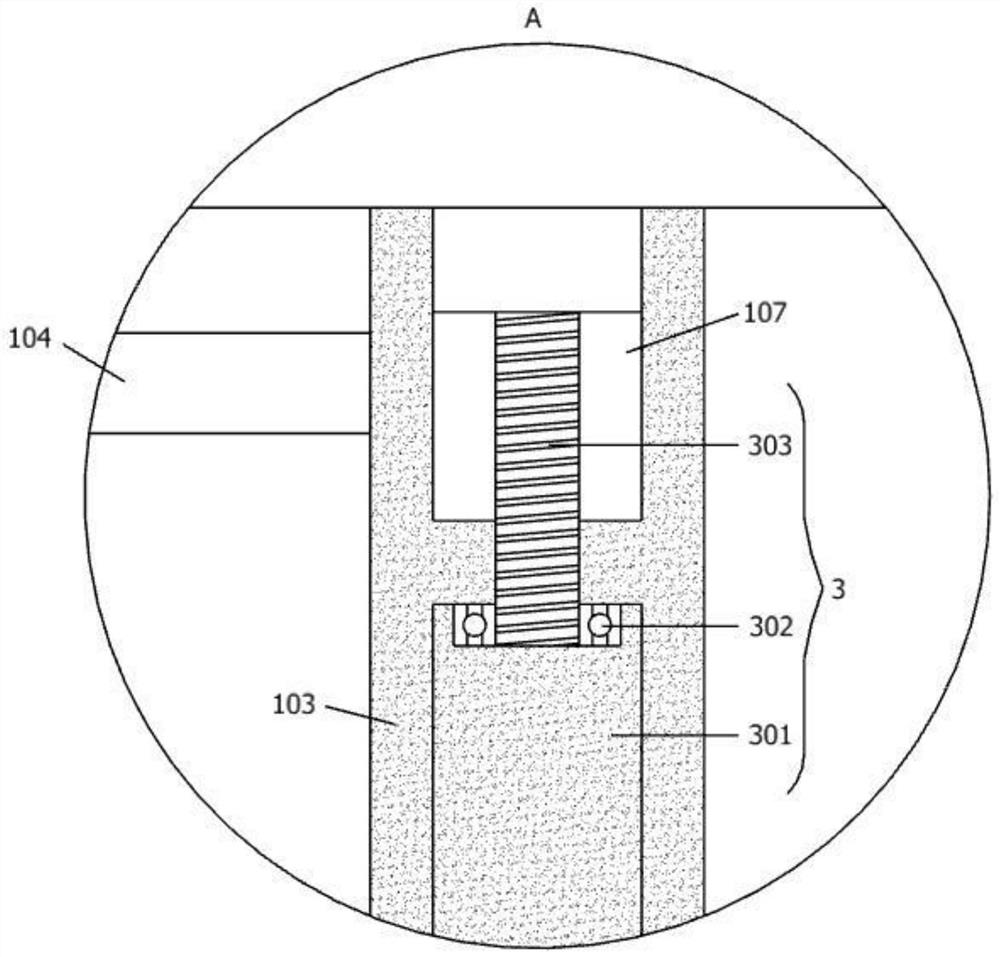

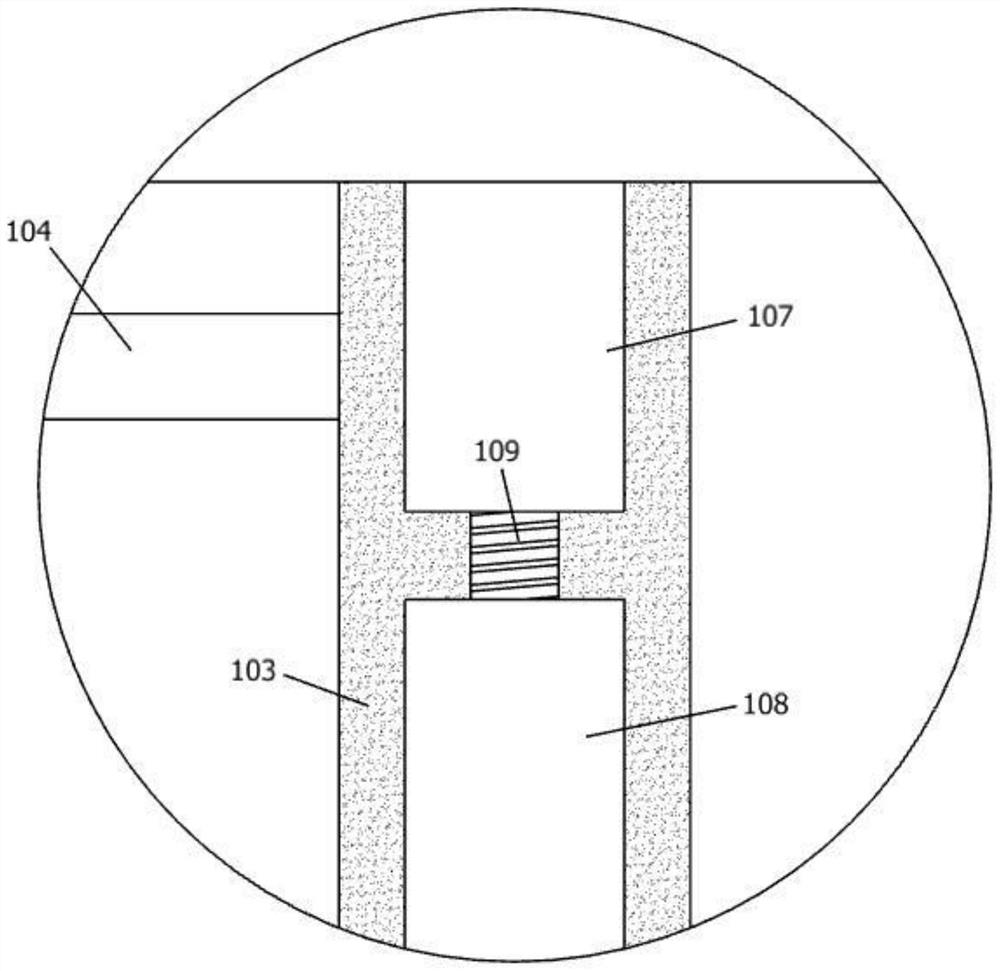

[0025] Append figure 1 Adherent Figure 6 Down:

[0026]The present invention provides a precision instrument electroplating method, and the precision instrument is electroplated by using a precision instrument electroplating device, and thereby completing the electroplating of precision instruments; the precision instrument electroplating apparatus includes: electroplating groove main body 1, plating tank The upper right side of the main body 1 is slid to be mounted with a closed mechanism 3, and the upper left side of the electroplating groove body 1 is slidable with a sliding plate 2; the electroplating groove body 1 includes a plating groove 101, a support frame 102, and a partition plate 103, a plating tank main body 1. The top end surface is opened with a plating tank 101. The electroplating groove body 1 is fixedly mounted with a support frame 102, and a partition plate 103 is fixed in the right side of the electroplating groove 101, and the front end surface of the partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com