A kind of steel box girder construction method

A construction method and technology of steel box girder, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of complex procedures and low work efficiency, and achieve the effect of simple process and high jacking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

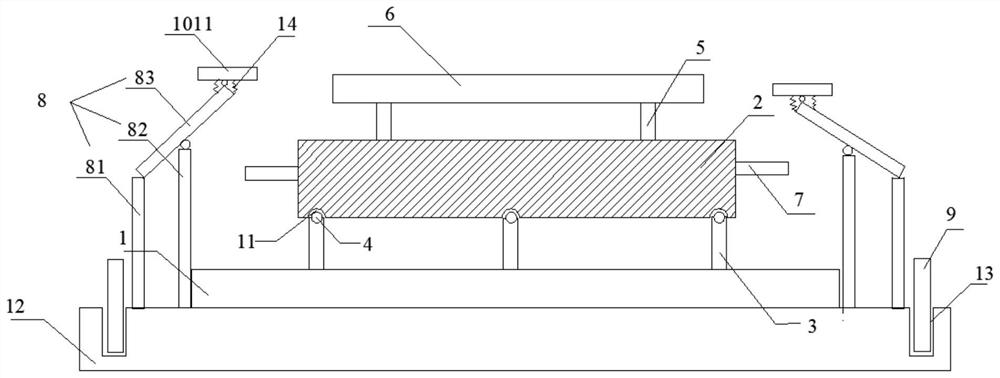

[0069] According to a preferred embodiment of the present invention, the walking jacking device includes:

[0070] support 1;

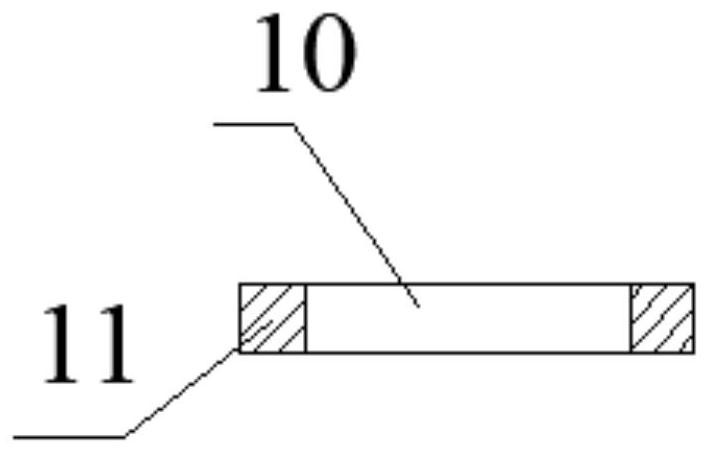

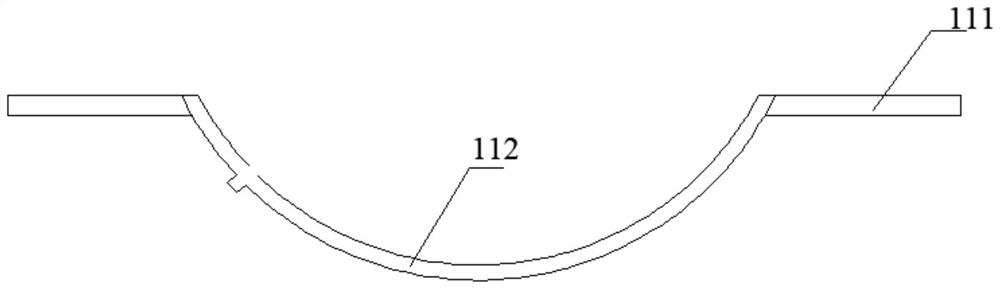

[0071] The jacking main body 2 is disposed on the support 1 through a plurality of first jacks 3, and the positions of the support 1 corresponding to the telescopic ends of each of the first jacks 3 are indented to form an arc A hinged ball 4 is rotatably hinged on the telescopic end of the first jack 3, and the hinged ball 4 is rotatable and does not fall off and is arranged in the limiting groove 11, so as to realize all the The connection between the first jacking jack 3 and the support 1; by controlling the jacking degree of the first jacking jack 3, the inclination angle of the jacking main body 2 is controlled;

[0072] A plurality of second jacking jacks 5 are arranged on the support 1 and located at the top of the pushing main body 2, wherein the top of the second jacking jacks 5 is vertically provided with a top plate 6, and the top plate 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com