Assembly type protective shelter

A prefabricated bunker technology, applied in the field of bunkers, can solve the problems of poor comfort, small resistance, and small protective bunker space, and achieve the effects of ensuring personnel safety, high bending and torsional strength, and good overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

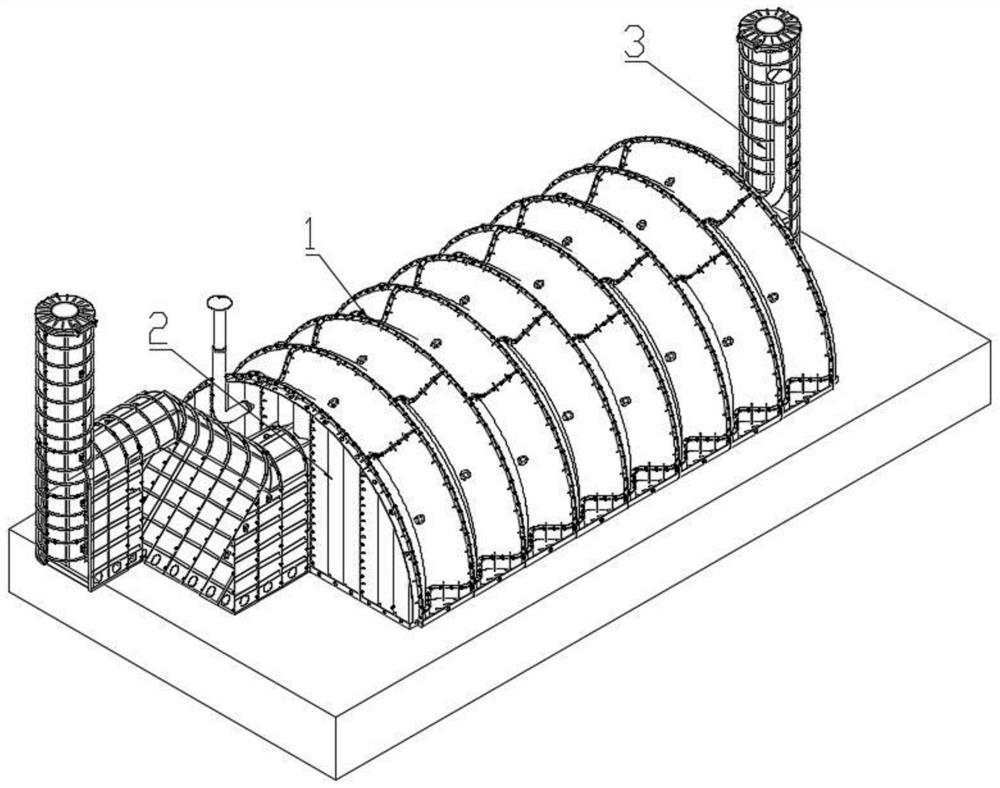

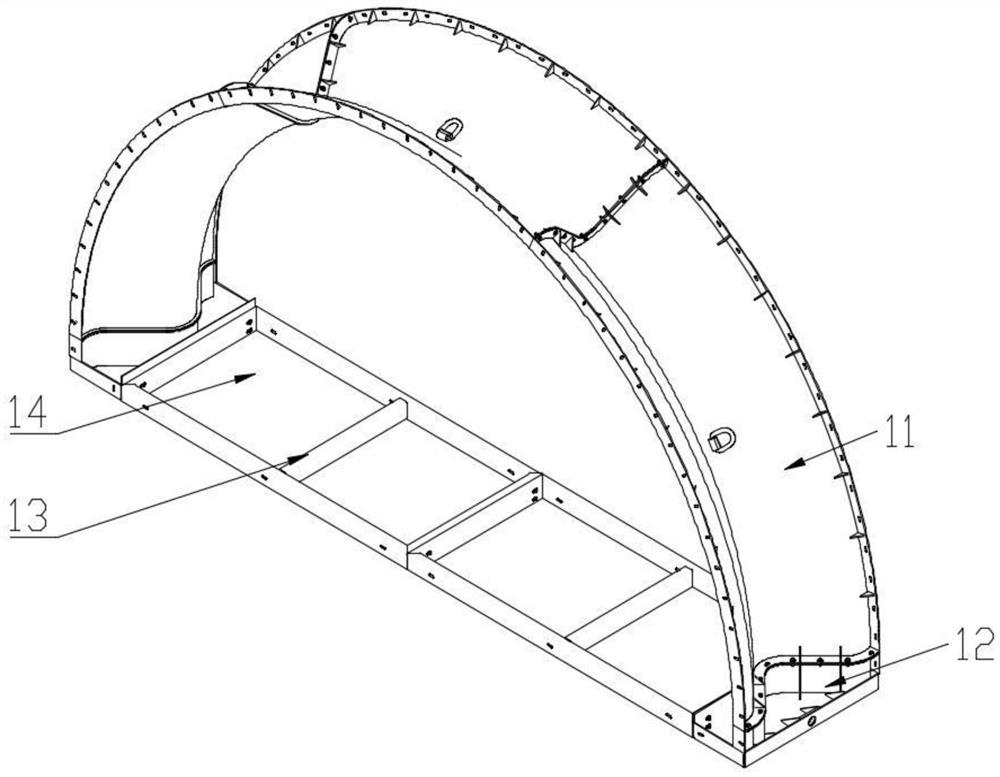

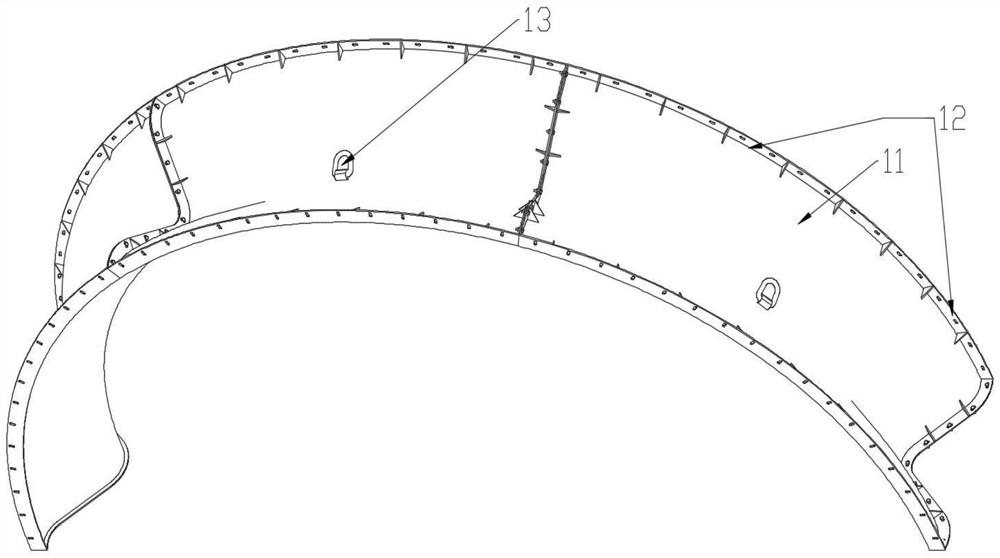

[0053] An assembled protective bunker includes a mask structure 1, an end structure 2, an ingoing channel structure 3, and the inlet and outgoing channel structure 3 is disposed on one side of the mask structure 1, the end structure 2 distributed in the mask structure. The sides of 1 form a closed space, the inlet and outgoing channel structure 3, and the end structure 2, the mask structure 1 consists of several single arch and standard interfaces, the single arch being connected by a standard interface, the single arch Also included, carrying the base 13 and the pedal 14, the pedal 14 is attached to the inside of the carrier base 13, and the carrier base 13 is composed of two unit base connecting, and the unit base is mainly formed by a rectangular tube welded to project, in the unit base. The waist hole is opened, and the waist hole is evenly distributed around the unit base, and the rapid construction mounting between each unit base is provided, and the pedal 14 is provided in ...

Embodiment 2

[0055] An assembled protective mask includes a mask structure 1, an end structure 2, an ingoing channel structure 3, and the input channel structure 3 is disposed on one side of the mask structure 1, the input channel structure 3 and an end structure. 2 Connect, the inlet and outgoing channel structure 3 includes a first rapid outlet 31 and a passage, and the first rapid outlet 31 and the channel are respectively disposed on both sides of the mask structure 1, which uses an L-type passage 32, the L-type The passage 32 adopts the personnel to climb the ladder climbed into and out of the mask structure 1, which is divided into a vertical passage 321 and a horizontal passage 322 to reduce the channel weight, to facilitate the construction mounting of the mask structure 1, and design the channel design For the multi-stage structure, the vertical passage 321 performs symmetricalation per segment, so that the channel height can be adjusted according to the landfill depth of the branch, ...

Embodiment 3

[0057] An assembled protective bunker, and the structure is basically the same as that of Example 2, which will only be described with reference to the contents of Example 2 in order to facilitate the description and saving space.

[0058] Such as Figure 8 - Figure 9 As shown, the carrier nested two-way closed door 33 easily opens the door when the inlet and export can cover the door, facilitate the person to get out of the bunker, so that the person cannot be opened upwards when there is a heavy refractive passage. In the dysfunction, the bidirectional door 33 is mainly composed of different sizes, the outer circular door body, the small door 332 is embedded in the center of the outer gate 331, and the outer door 331 and the interior small door 332 are provided with radiationability. Strengthen the ribs, the door 331 and the small door 332 ensure a certain steel intensity when the object is placed; the other large, the periphery of the small door 332 is provided with sealing stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com