Cryogenic top-mounted fixed bevel ball valve

An inclined surface and installed technology, applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as complex structures, troublesome assembly and disassembly maintenance, etc., to ensure safety and reliability, solve abnormal boosting, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

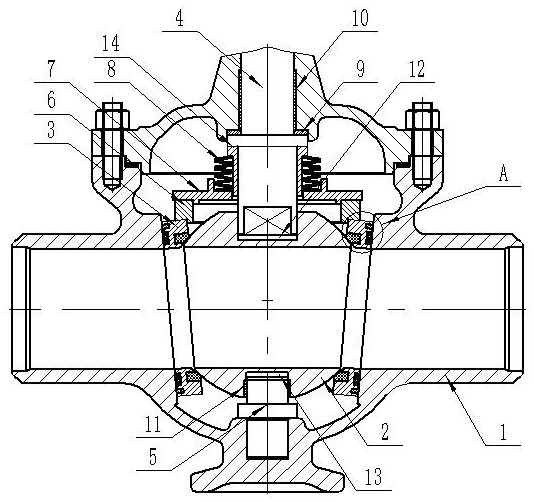

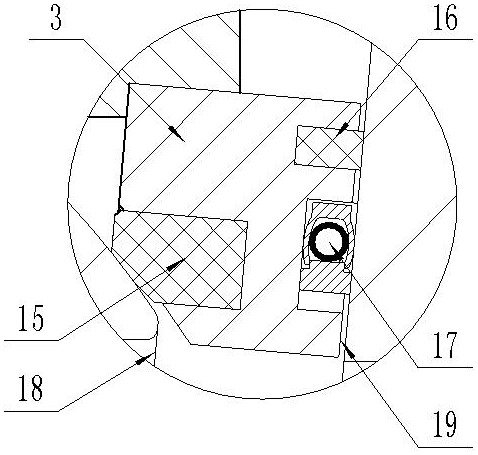

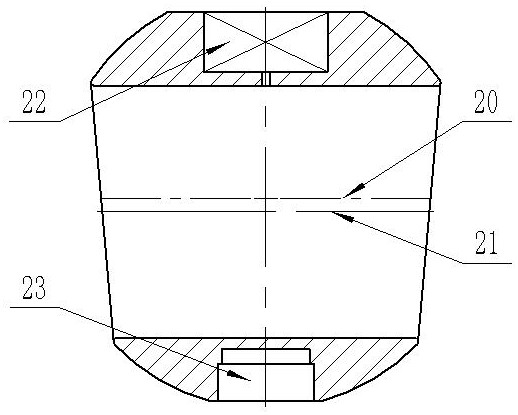

[0023] As shown in the figure, a cryogenic top-mounted fixed inclined ball valve includes a valve body 1, a ball 2, a valve seat 3, an upper valve shaft 4, a lower valve shaft 5, a pressure ring 6, a pressure plate 7, a bushing 14, and a ball 2 The two sides of the ball mouth are inclined wedge surfaces 18, and the inclined wedge surfaces 18 are parallel to the back inclined surface 19 of the valve seat. The upper end of the ball 2 is provided with a tenon groove 22, and the tenon groove 22 cooperates with the lower end of the upper valve shaft 4 to form a cavity. I12, the lower end of the sphere 2 is provided with a stepped hole 23, and a sliding bearing I11 is provided between the stepped hole 23 and the upper end of the lower valve shaft 5, and the stepped hole 23 and the upper end of the lower valve shaft 5 cooperate to form a cavity II13 to ensure the vertical spring 8 can provide sufficient sealing specific pressure between the ball 2 and the sealing ring I15, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com