Water conservancy project discharge pipeline

A technology for water conservancy projects and pipelines, which is applied in the direction of pipe components, pipes/pipe joints/fittings, cleaning hollow objects, etc. It can solve the problems that impurities such as sediment cannot be cleaned independently, the normal operation of water conservancy projects is affected, and the dredging of drainage pipes is interrupted. Achieve the effect of improving self-protection ability, improving drainage efficiency and increasing transmission pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

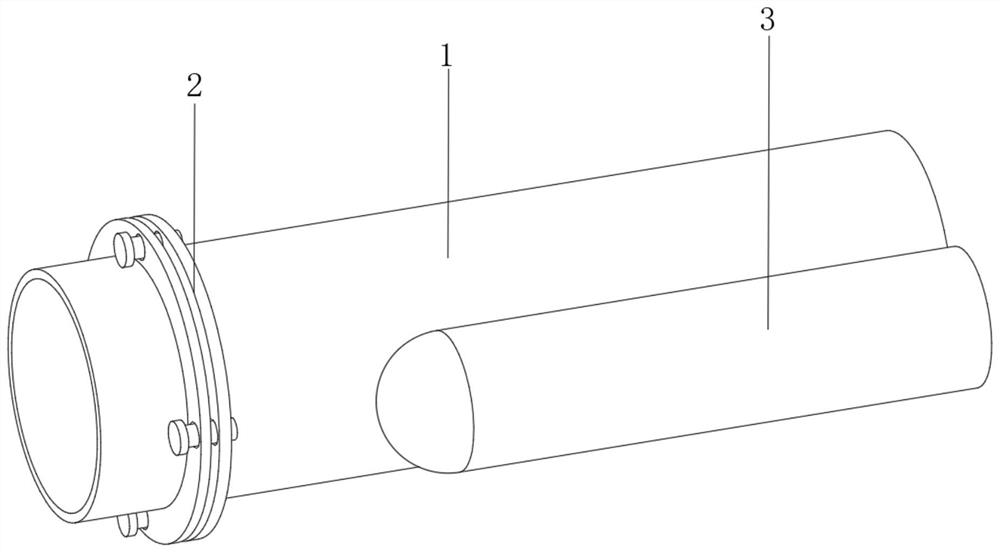

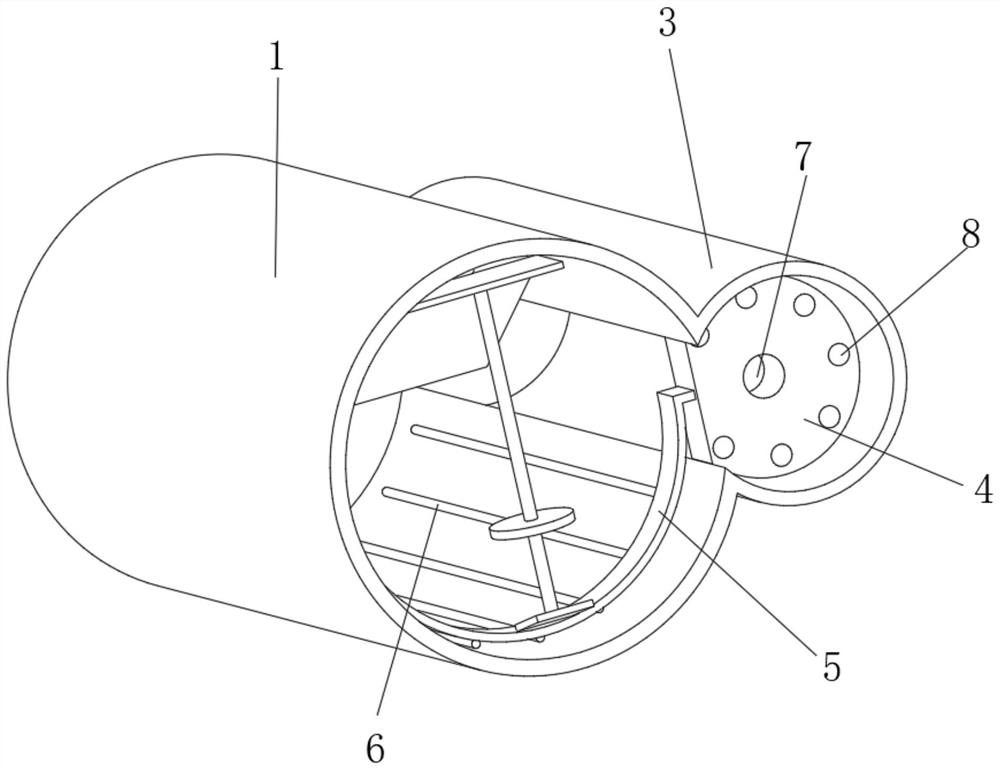

[0034] Such as Figure 1-3 As shown, the present invention provides a technical solution: a water conservancy project discharge pipeline, including a main drainage pipe 1, the left input end of the main drainage pipe 1 is fixedly connected with a mounting flange 2, and the middle position of the outer side of the main drainage pipe 1 The auxiliary side pipe 3 is fixedly connected, and the middle position inside the auxiliary side pipe 3 is slidably connected with the driving blocking plate 4, and the side of the driving blocking plate 4 close to the main drain pipe 1 is fixedly connected with the transmission scraping mechanism 5, and the transmission scraping mechanism 5 Extending to the bottom end of the main drain pipe 1, the surface of the inner bottom end of the main drain pipe 1 is uniformly and fixedly connected with a cleaning liquid supply mechanism 6, and the center of the drive blocking plate 4 is provided with a transmission connection hole 7, and the drive blocking...

Embodiment 2

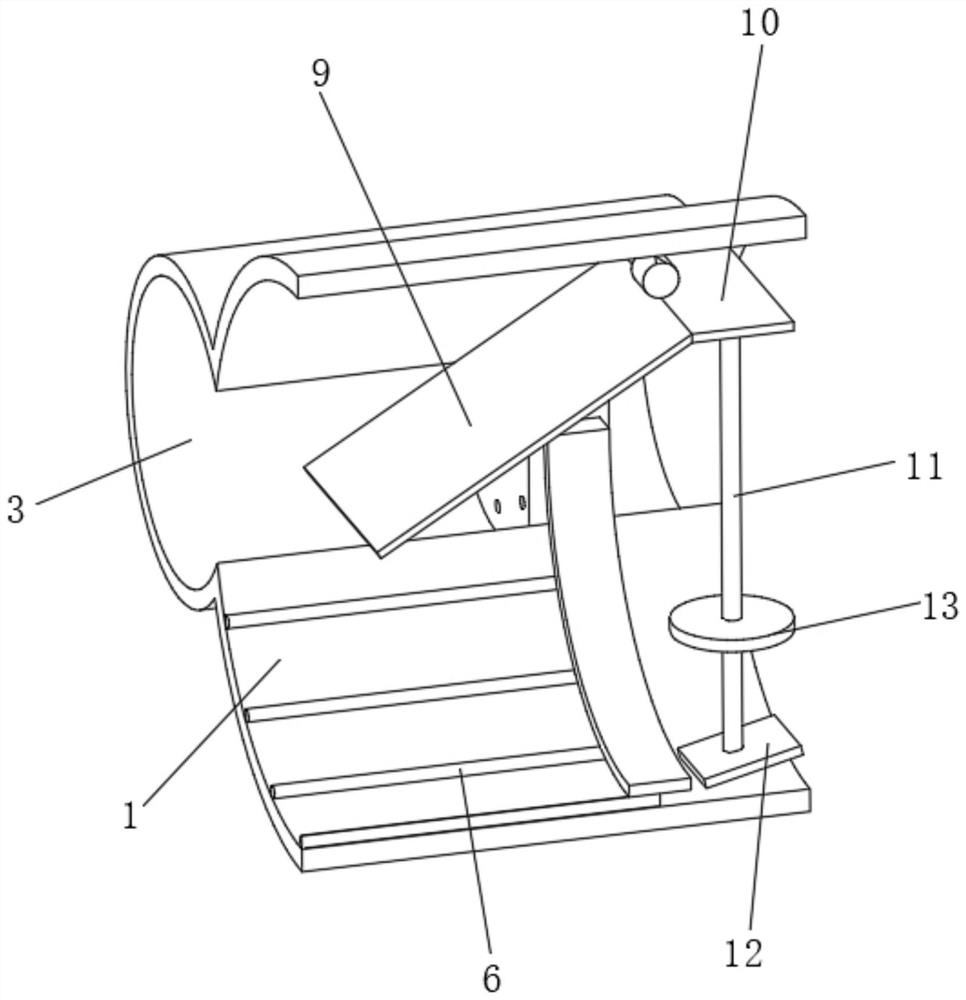

[0038] Such as Figure 4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a water conservancy project discharge pipeline, the transmission scraping mechanism 5 includes a scraping top plate 51, and one end above the scraping top plate 51 is fixed to the driving blocking plate 4 Connection, the left side of the scraper top plate 51 is fixedly connected with a contact limiting plate 52,

[0039] Both sides of the inner bottom of the scraper top plate 51 are provided with a cleaning limit frame 53, and the middle position of the cleaning limit frame 53 is connected with an elastic shaft wheel 54 for rotation, and the outer surface of the elastic shaft wheel 54 is evenly fixedly connected with a scraper blade 55.

[0040] On the outer side of the contact limiting plate 52 near the upper position is provided with a clamping conduction port 56, inside the contact limiting plate 52 near the upper position is provided with a conduction inner...

Embodiment 3

[0042] Such as Figure 5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a water conservancy project discharge pipeline, the cleaning liquid supply mechanism 6 includes a conical groove 61, and the bottom of the conical groove 61 is connected with the main drainage The bottom end of the tube 1 is fixedly connected, the right side of the limiting cone groove 61 is fixedly connected with a sealed liquid storage tank 62 , and the left input end of the limiting cone groove 61 is fixedly connected with a one-way bellows 63 .

[0043] The middle position inside the sealed liquid storage tank 62 is slidably connected with a gasket block 64 , the right side of the gasket block 64 is fixedly connected with a transmission strut 65 , and one end of the transmission strut 65 located outside the sealed fluid storage tank 62 is fixedly connected with a contact pressure The conductive block 66 , the contact pressure conductive blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com