Motor vehicle with two-level underfloor deflector

A technology of motor vehicles and deflectors, applied in motor vehicles, in the field of vehicles, vehicles, can solve the problems of deployment mechanism maintenance hindering the widespread use of the system, and achieve the effect of solving the damage problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following description, the term "comprises" is a synonym for "comprises" and, without limitation, other elements may be present in the vehicle or underfloor spoiler to which the term relates. The term "comprising" includes the term "consisting of". The terms "lower", "upper", "front", "rear" are to be understood with respect to the usual orientation of the vehicle. The terms "lower" and "lower" mean closer to the ground in a vertical direction than the terms "upper" or "higher". The term "front" denotes an orientation oriented in the horizontal direction towards the front of the vehicle, and the term "rear" denotes an orientation oriented in the same direction towards the rear of the vehicle. On the different drawings, the same reference numbers indicate the same or similar elements.

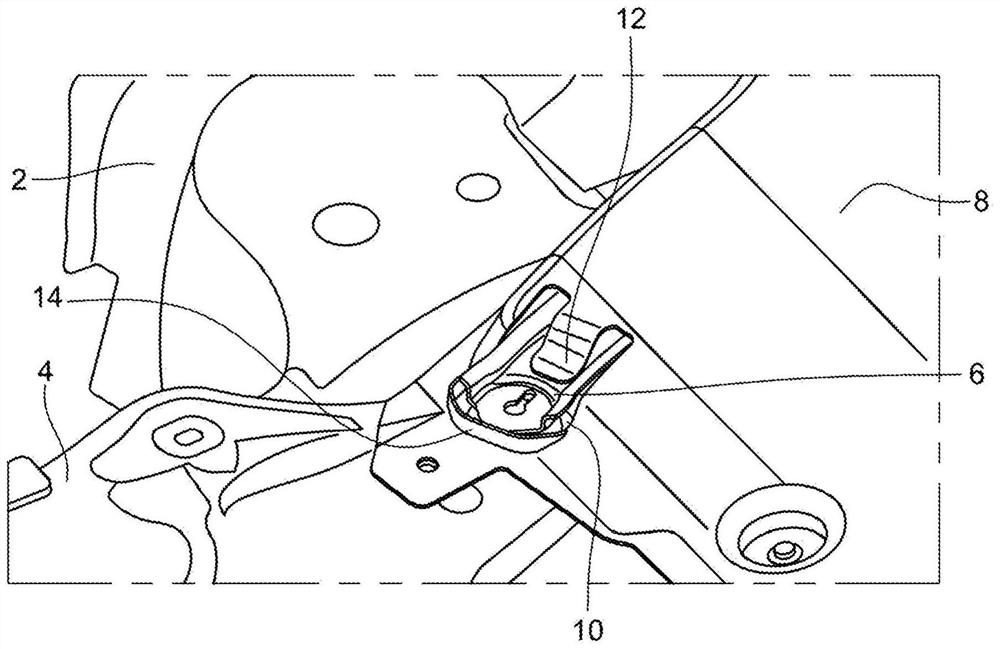

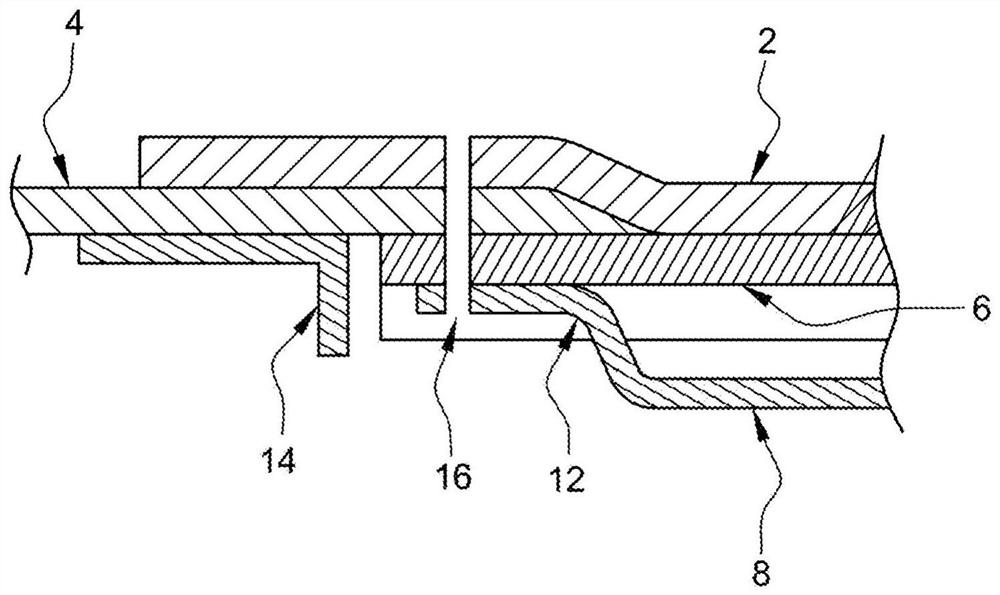

[0024] First, refer to figure 1 . The underframe 2 is the part that serves as a base for the chassis of the motor vehicle. This section is the most exposed to water, mud, grav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com