Precise laser welding combined clamp for large-diameter thin-wall round pipe

A laser welding and combined fixture technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of easy damage to the outer wall surface, low positioning accuracy, deformation of joints, etc., to reduce the risk of local deformation, High coaxiality requirements and the effect of reducing radial runout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

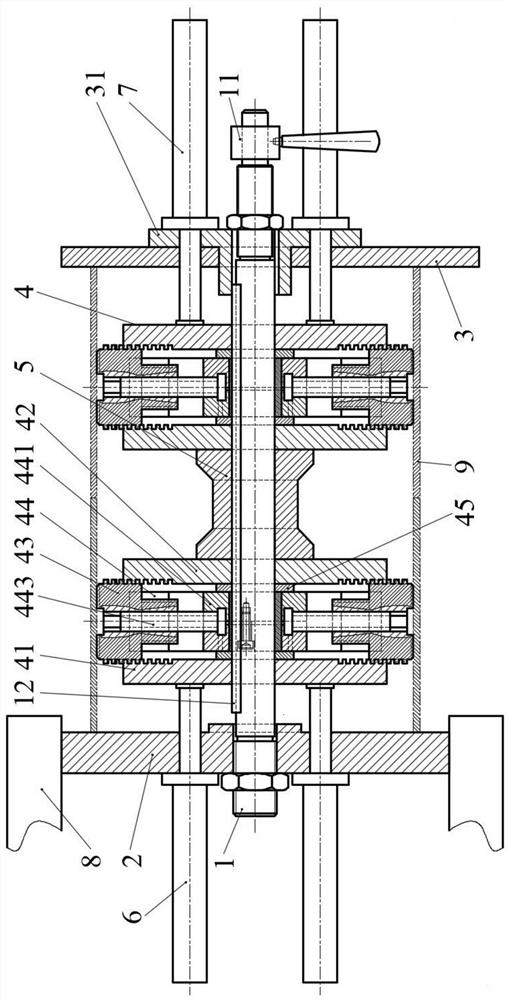

[0032] Below in conjunction with accompanying drawing, the present invention will be further described (hereinafter referred to as figure 2 , Figure 10 The direction to the right of the front is described as the front).

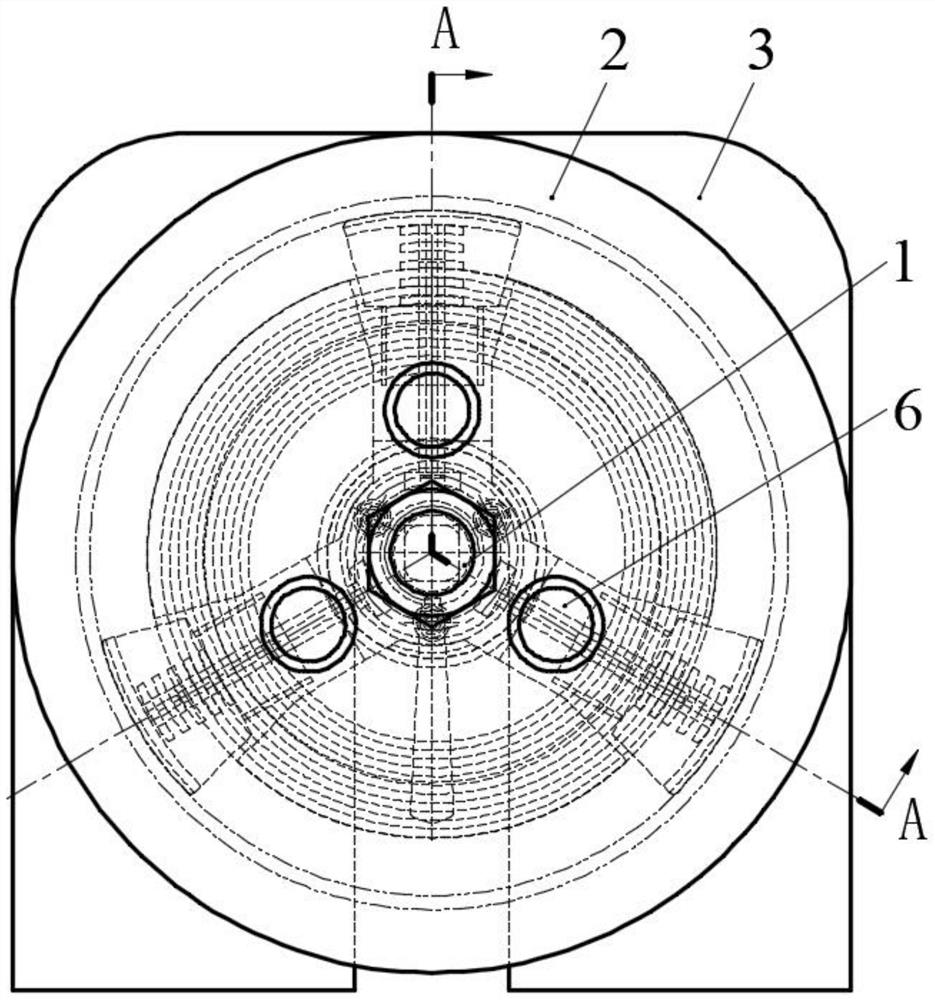

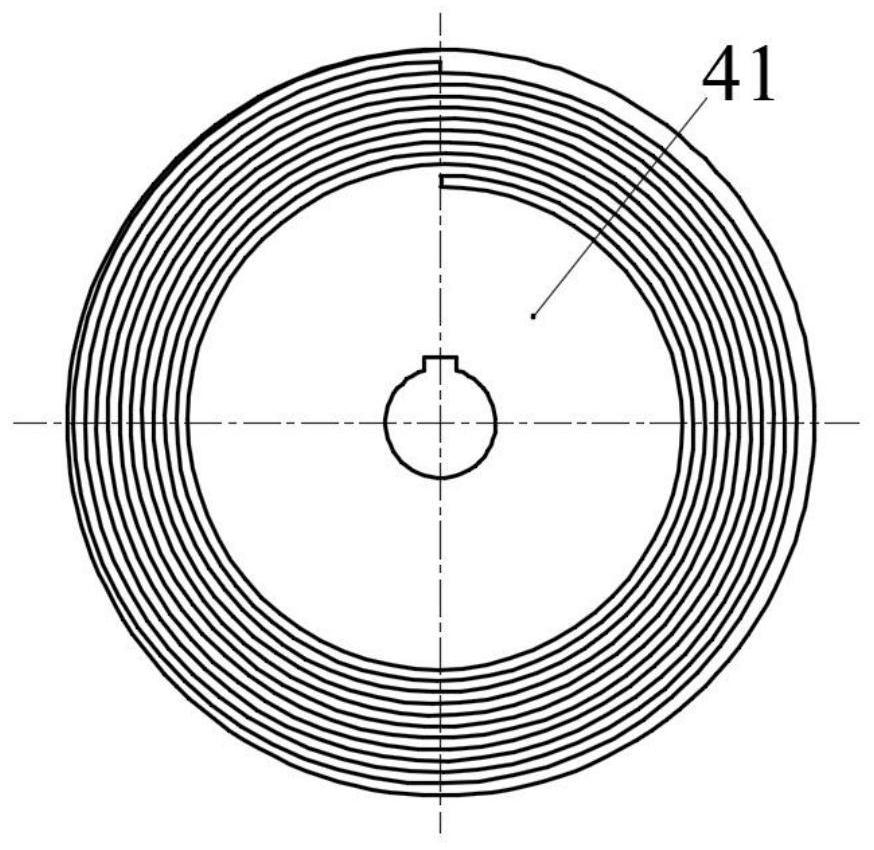

[0033] Such as figure 1 , figure 2 , Figure 10 As shown, the large-diameter thin-walled circular tube precision laser welding combined fixture includes a supporting spindle 1, a rear positioning plate 2, a front positioning plate 3, a radial positioning clamping device assembly and an axial adjustment device.

[0034] The rear end of the supporting main shaft 1 is axially positioned and installed at the axis position of the rear positioning disc 2 of the disc structure, and the supporting main shaft 1 and the rear positioning disc 2 are installed in rolling fit, and the front end of the supporting main shaft 1 is provided with a quick connection structure , and the quick connection structure is provided with a rotary handle 11 that is installed in con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com