Novel cutter head

A cutter head, a new technology, applied in the field of processing tools, can solve the problems of applicability and practicability limitations, unfavorable maintenance and maintenance, and inability to adjust, etc., to achieve the effect of good practicability, fast and effective installation and positioning, and accurate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

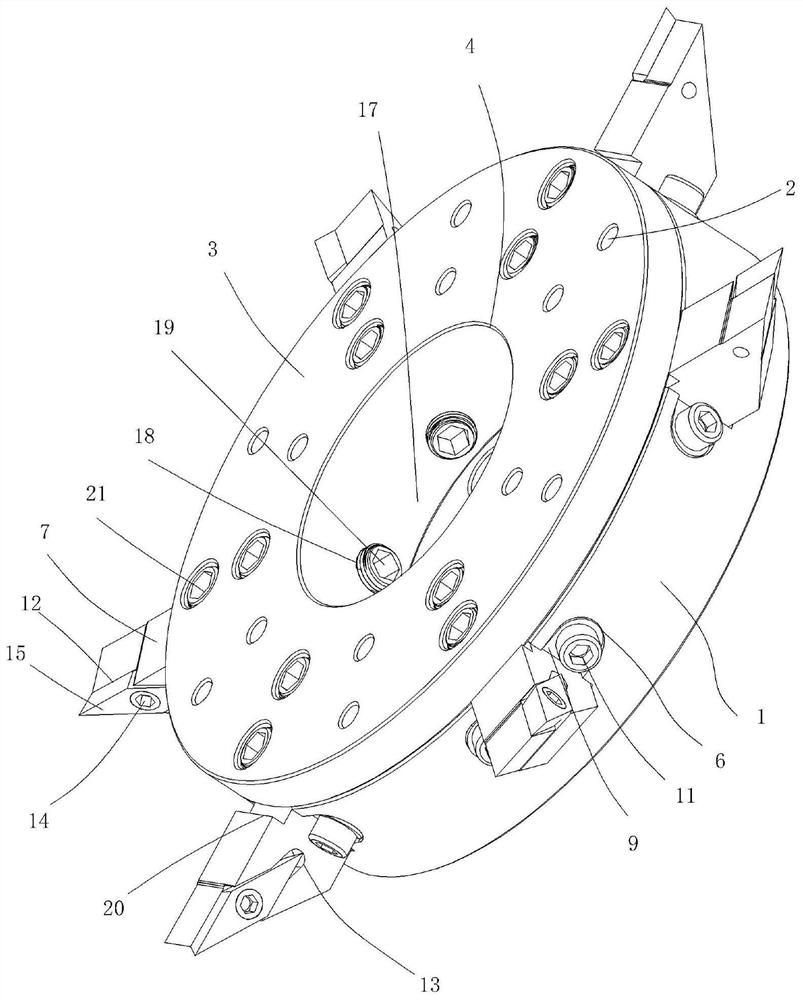

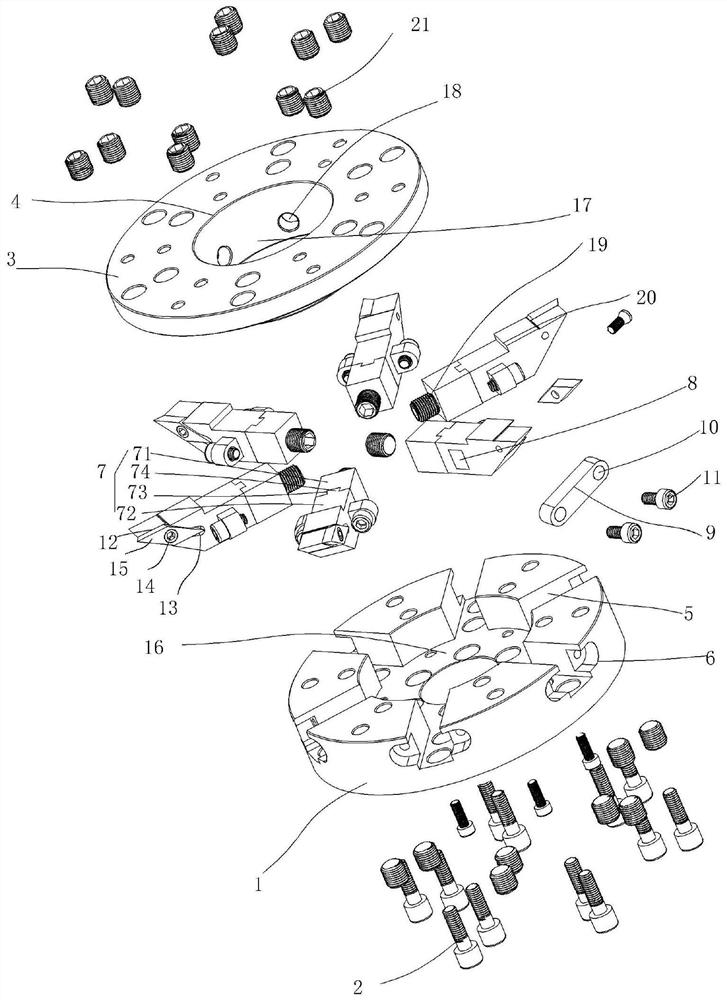

[0014] figure 1 and figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic diagram of dismantling structure of the present invention. In this embodiment, directional words such as knife upper plate and knife lower plate are for convenience of description, and are not intended to limit them.

[0015] See figure 1 and figure 2 , a new type of cutterhead, comprising a lower cutterhead 1 and an upper cutterhead 3 connected to the lower cutterhead by screws 2, the center of the upper cutterhead and the lower cutterhead is provided with a round hole 4 for installation, the The top surface of the lower plate of the knife is equidistantly provided with the handle installation slot 5, and the outer wall of the lower plate of the knife is provided with a locking avoidance groove 6, and the locking avoidance groove is located at the symmetrical edge of the handle installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com