A comprehensive seismic steel structure and its installation and construction method

A technology of anti-seismic steel and components, applied in the direction of anti-seismic, building components, building structure, etc., can solve the problems of poor anti-seismic effect of steel structure, ability to resist vibration load, and fatigue strength of vibration load not up to standard, short service life of components, etc. Improve the effect of elastic support, good seismic effect, strong versatility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following will be described in detail to the embodiments of the technical scheme of the present invention. The following examples are only used to explain the technical solutions of the present invention more clearly, so they are only used as examples, and they cannot limit the protection scope of the present invention.

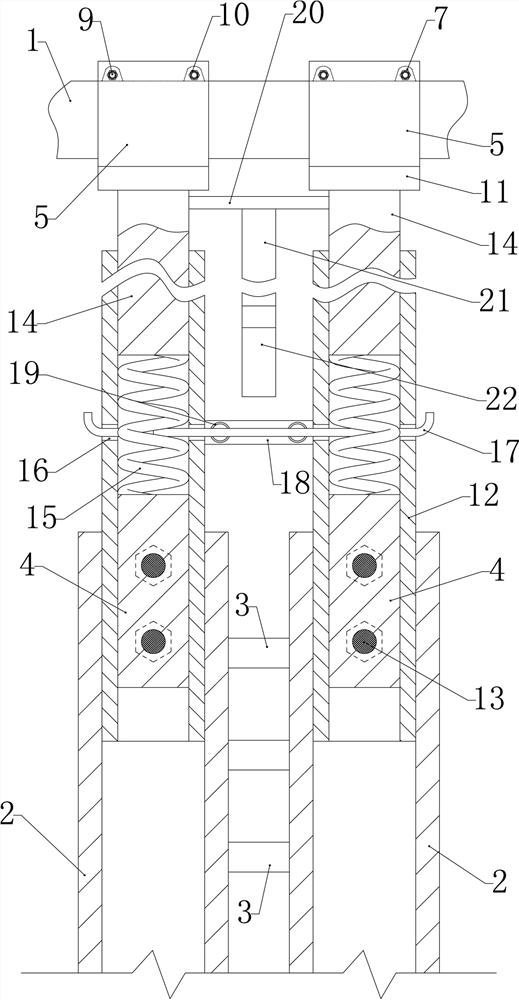

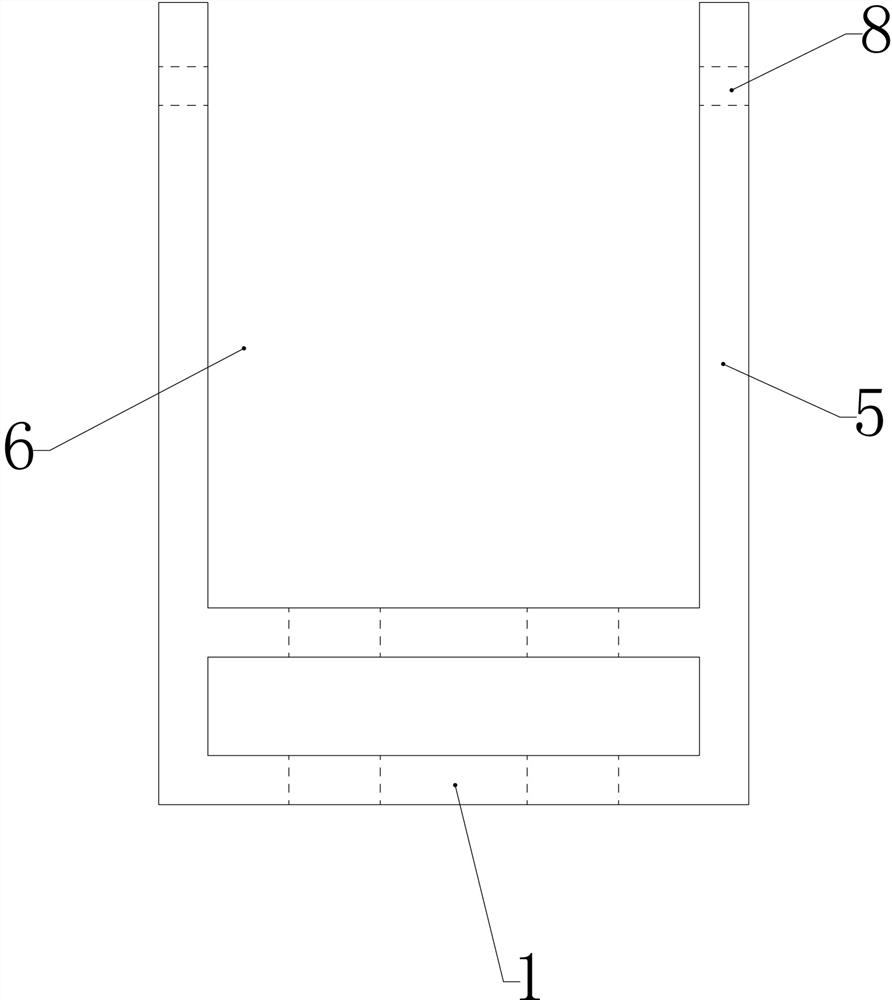

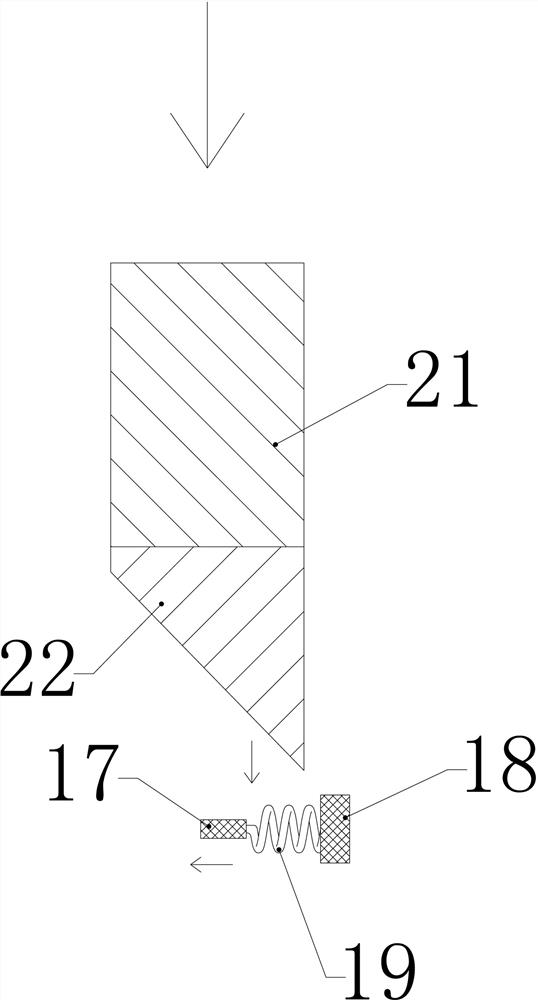

[0047] like Figure 1-4 中所示,本发明为解决上述技术问题之一,所采用的技术方案是:一种综合抗震钢结构,包括钢梁构件1、承托钢柱构件,所述钢梁构件1水平设置,在Below of the steel beam component 1 is provided with several supporting steel column components, each of which has a vibration reducing buffer component between the request steel column components and the steel beam component 1, respectively. The components are solid with the steel beam component 1 through the above -connected components. Each vibration reduction buffer component is based on the bolt parts with the corresponding supporting steel column component. Each of the supporting steel column components is realized in the vibration of steel beam components 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com