Circulating flame-retardant device and method for goaf under mine

A technology for gobs and underground mines. It is applied in mining equipment, safety equipment, mining equipment, etc. It can solve the problems that the coverage area is easily affected by environmental factors, the inhibitor is not easy to spray evenly, and the distance between spraying points is far away. Avoid spraying omissions, smooth and reliable operation process, and clear flame retardant track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

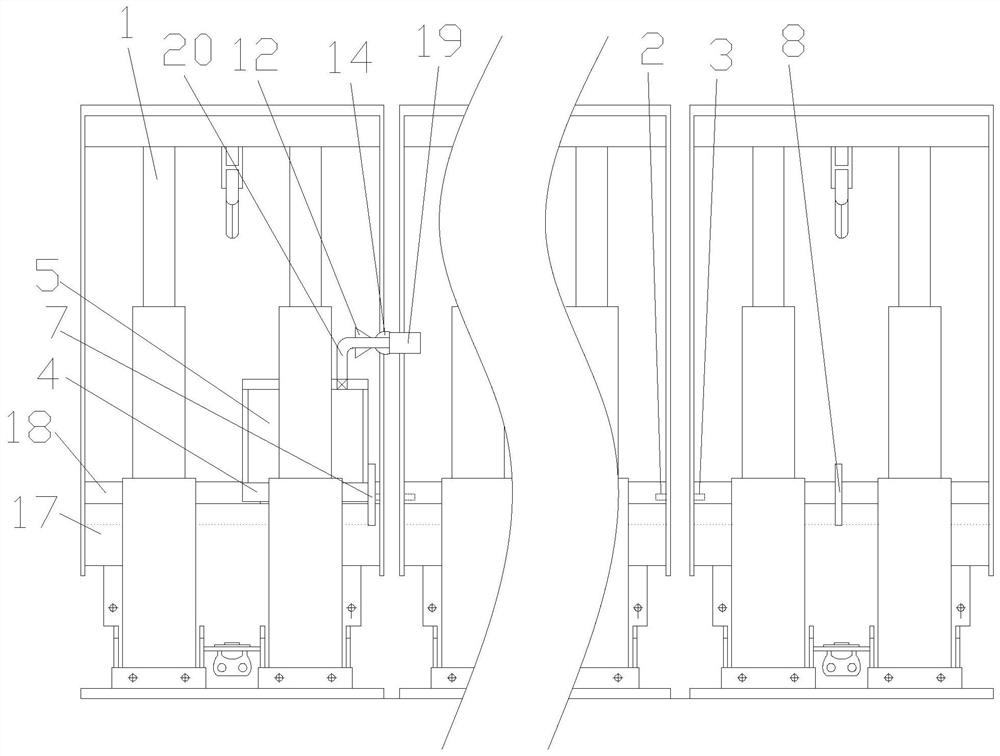

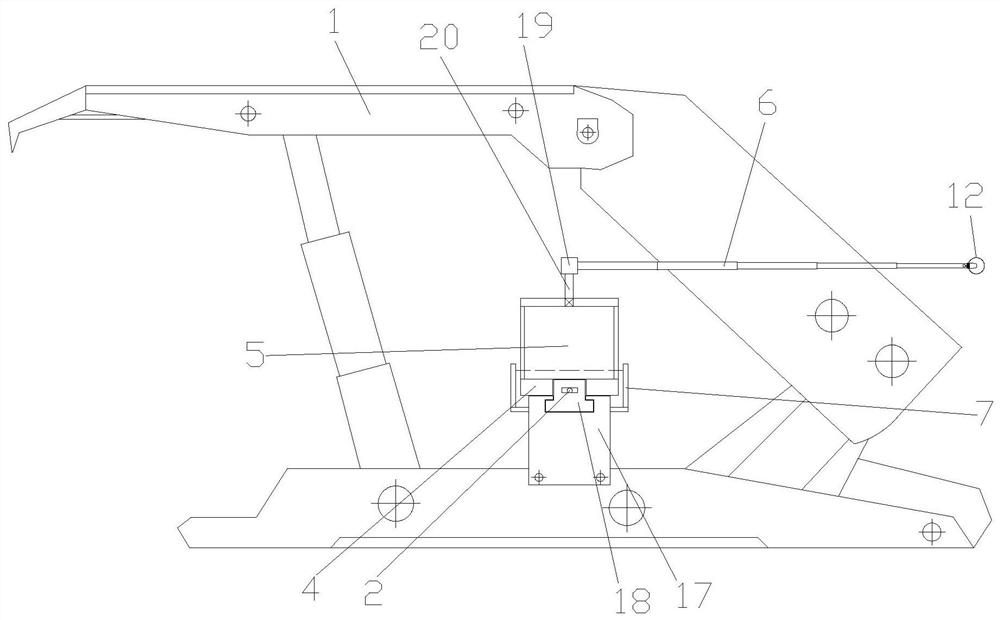

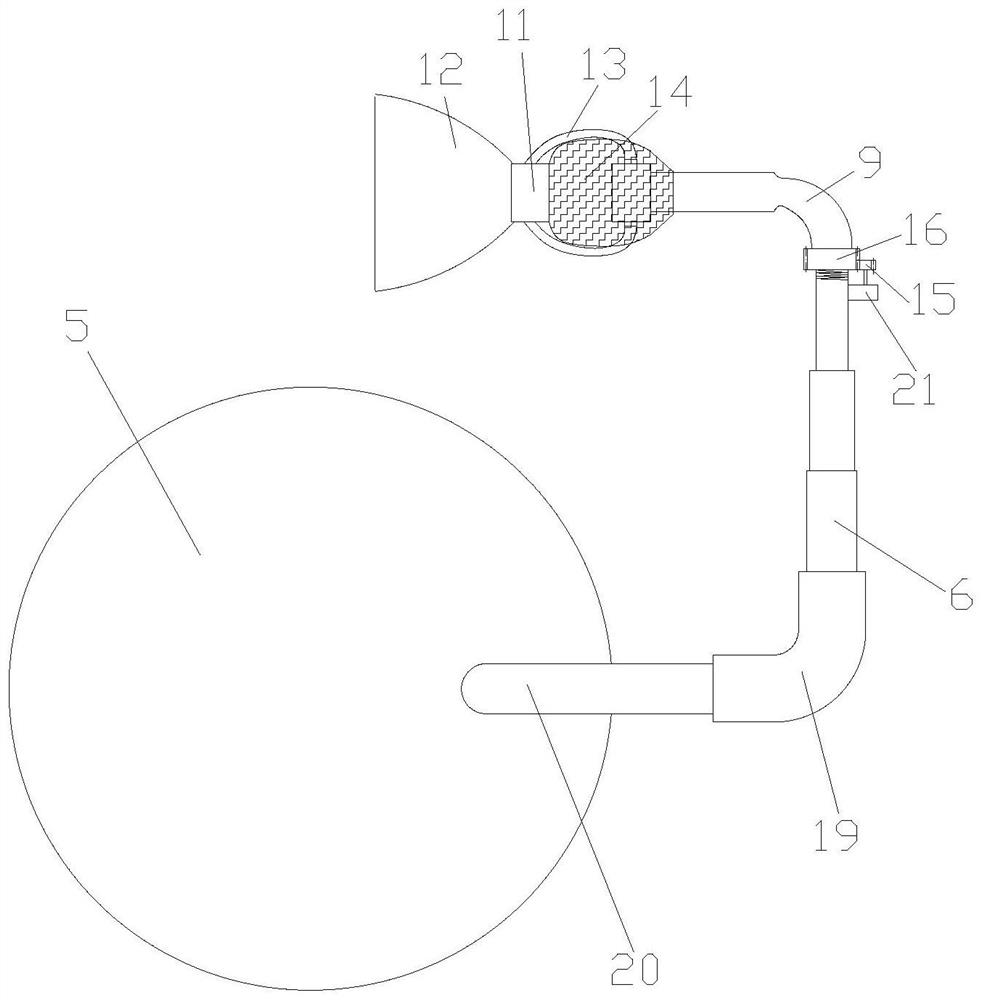

[0057] Such as Figure 1 to Figure 4 As shown in the present invention, a goaf circulating flame-retardant device for underground mines includes a guide base arranged on the base of the hydraulic support group of the coal mining machine and arranged along the width direction of the goaf, and on the A spraying device that reciprocates and slides on the guide base. The shearer hydraulic support group includes a plurality of shearer hydraulic supports 1. The guide base includes a plurality of guide units. The number of the guide units and the shearer hydraulic support 1 The same and one-to-one correspondence, the spraying device sprays the inhibitor to the goaf behind the shearer hydraulic support 1;

[0058] A signal sensing mechanism for controlling the operation of the spraying device is arranged between two adjacent guide units, and the signal sensing mechanism includes an infrared signal emitter 2 arranged at the end of one guide unit and an infrared signal emitter 2 arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com