Precise temperature control system suitable for factory cooling water

A technology of cooling water system and temperature control system, which is applied in household refrigeration devices, cooling fluid circulation devices, applications, etc., can solve the problems of inability to adjust the opening of the electronic expansion valve, and the range of temperature control is not wide, and achieves shortening Time and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objects, technical solutions, and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention will be clear and complete, and it is clear that the described embodiments are intended to be part of the invention, rather than all Embodiments.

[0026] Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

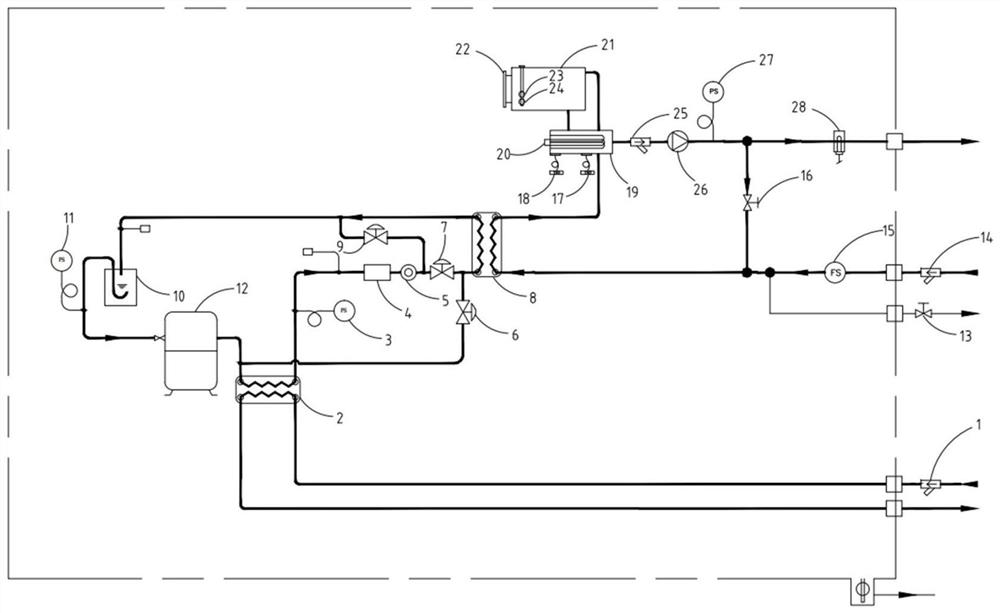

[0027] Such as figure 1 As shown, the circulating fluid system of the present invention includes a filter 14, a flow meter 15, an evaporator 8, a water tank 19, a filter 25, a water pump 26, a pressure table 27, a temperature sensor 28, and a temperature sensor 28. The PCW plant cooling water system in this embodiment includes a filter 1, a condenser 2 in sequential. The compressor refrigerant refrigeration system in this embodiment includes a compressor 12, an electronic expansion valve (HOT ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com