Microflow pipeline for gathering non-spherical micro swimming bodies and filtering method

A swimming body, non-spherical technology, applied in the field of microfluidics, can solve the problems of difficult construction and blockage of microfluidic pipelines, achieve the effect of simple structure and reduce the probability of pipeline blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

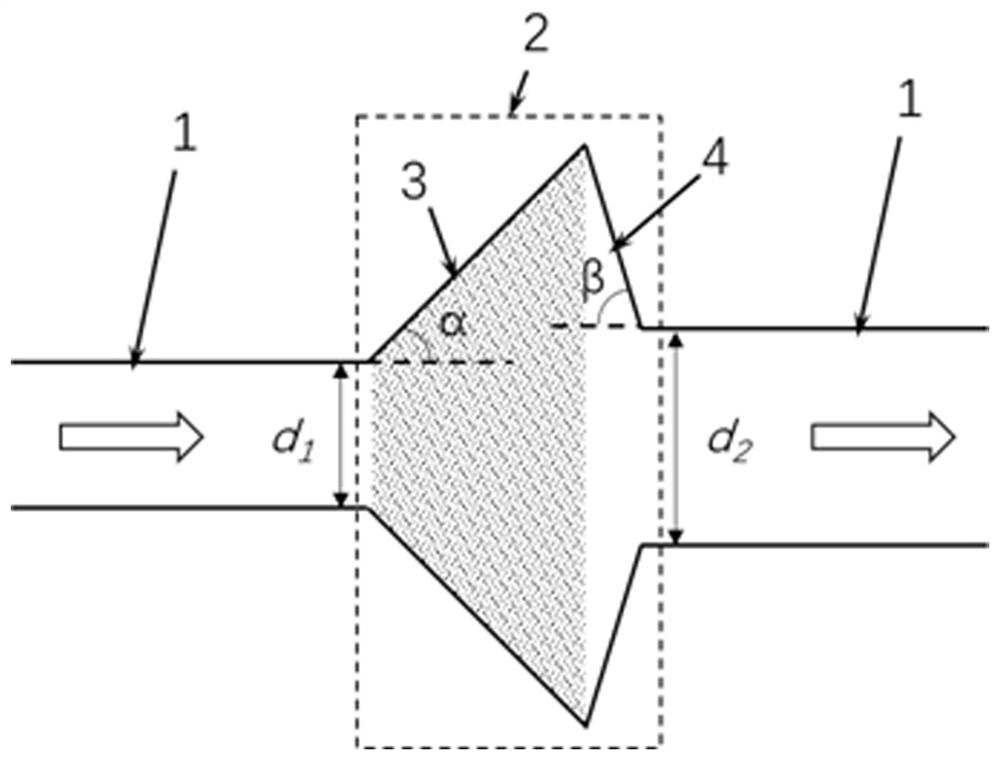

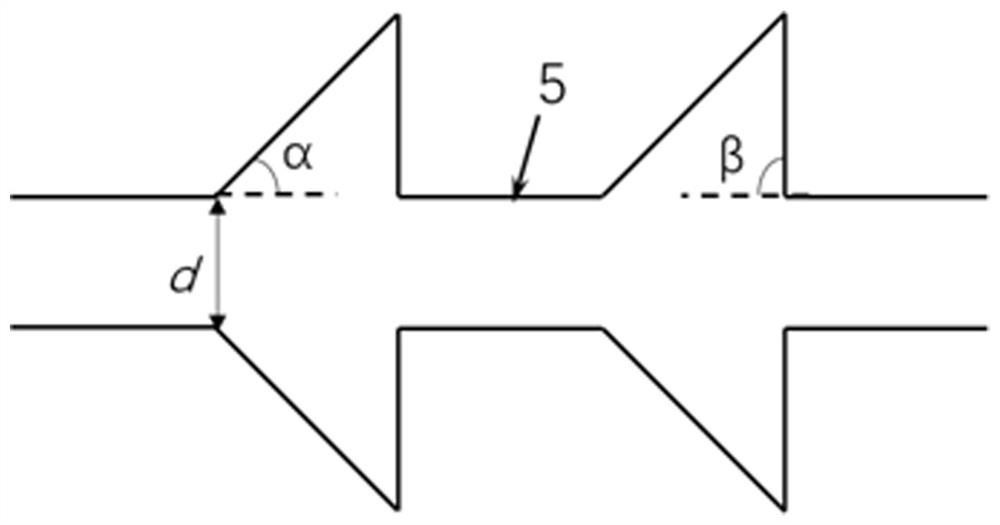

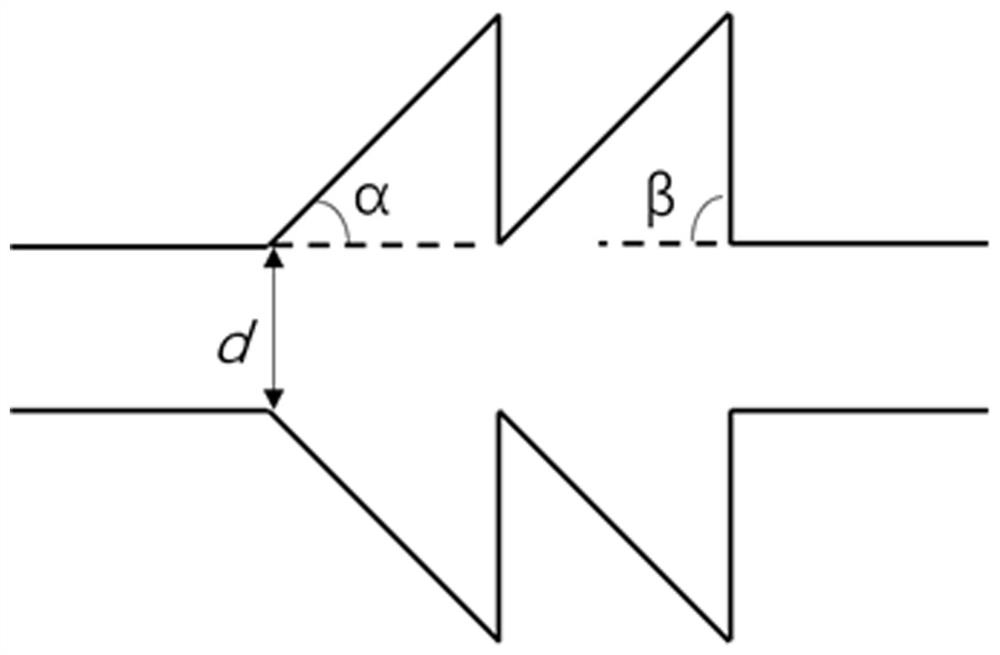

[0053]By photolithography on silicon wafers such as Figure 5 A microfluidic channel with aggregated non-spherical micro-swimming bodies, d=50 microns, α=45 degrees, is made into a PDMS channel with a thickness of 50 microns through reverse molding.

[0054] The Escherichia coli RP437 solution with an OD value of 0.1 was passed into the microfluidic channel, and the movement speed of RP437 was 20 μm / s.

[0055] Scanning in the flow range from 0.16 nL / s to 2.5 nL / s, it was found that the number density of aggregated regions was the highest at 0.5 nL / s.

[0056] Fix the flow rate to 0.5 nL / s, and the micrograph after 1 minute is as follows Figure 6 As shown, at this time, the inner area of the connecting section 3 of the expansion tube at the head end is the area of the expansion flow field, as shown in Figure 6 As shown in the dashed box, the number density in this area is 3.7 times the average number density in the pipeline under the condition of no flow velocity.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com