Drawing machine mold core replacement device and using method thereof

A technology of drawing machine and mold core, which is applied in the direction of wire drawing die, etc., and can solve the problems of disassembly and assembly of mold core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

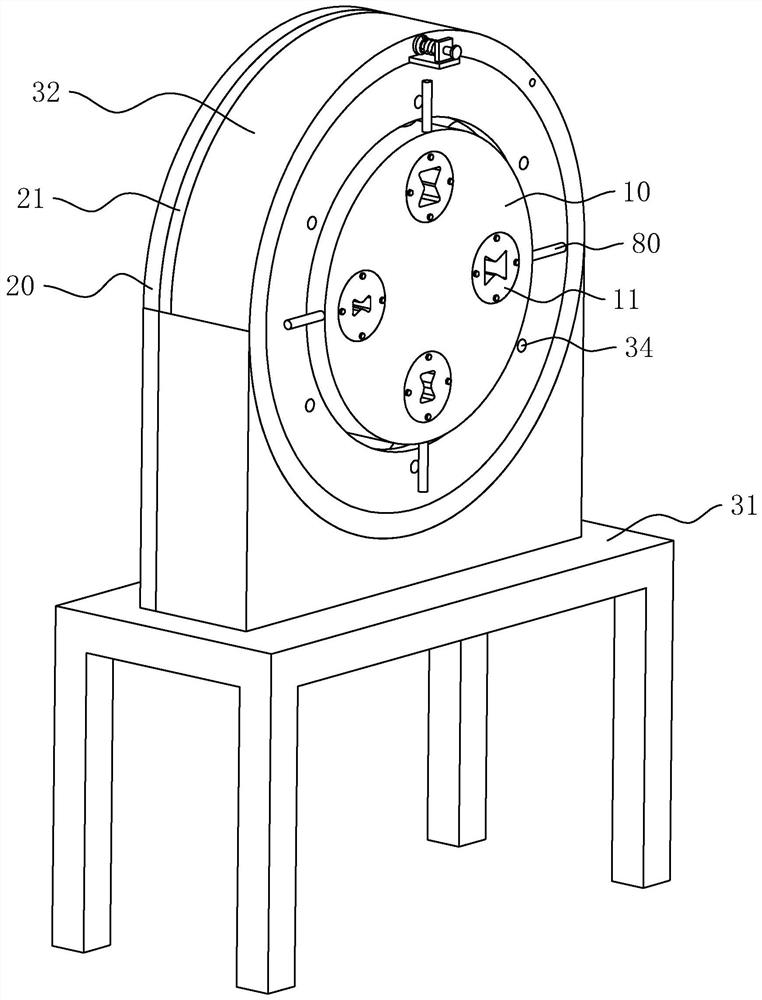

[0044] refer to figure 1 The device for replacing the core 11 of the drawing machine includes a support assembly, an installation assembly rotatably connected to the support assembly, an adjustment assembly for adjusting the rotation angle of the installation assembly, and a locking assembly for locking the support assembly and the installation assembly.

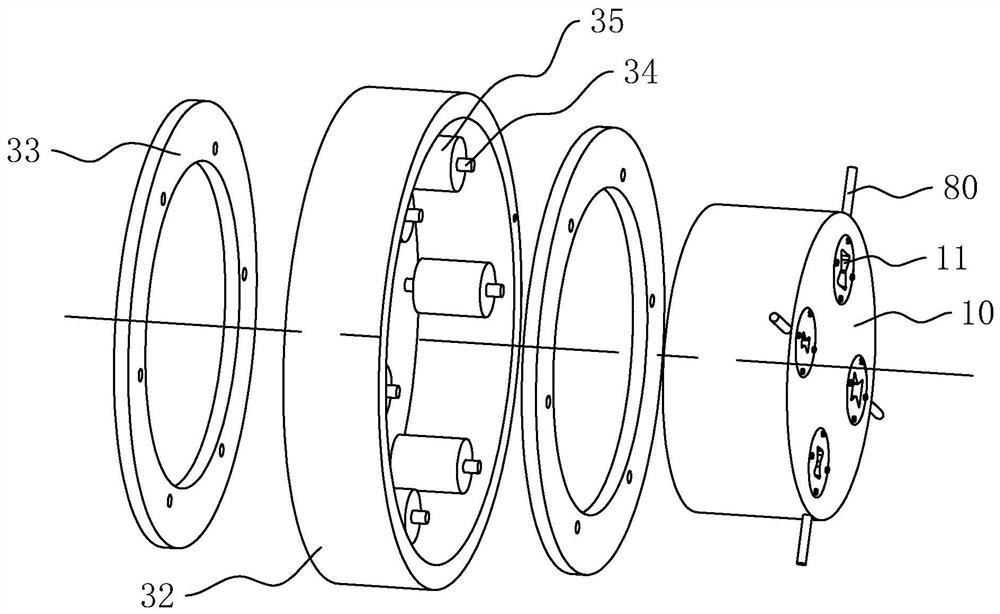

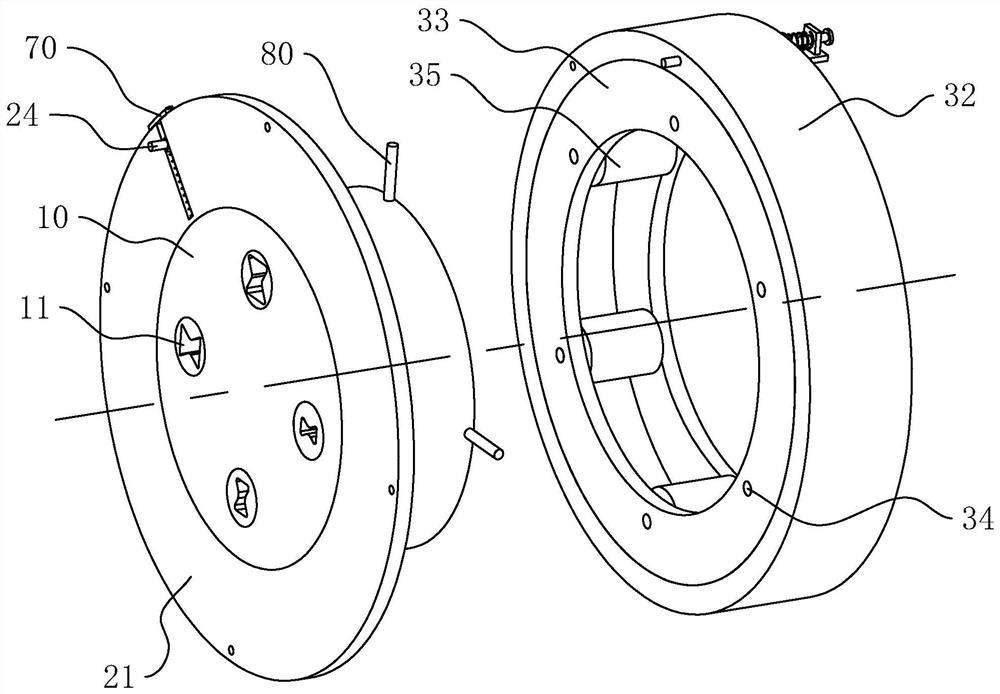

[0045] refer to figure 1 and figure 2 , the support assembly includes a support platform 31 , a support ring 32 , a bearing ring 33 , a bearing rod 34 , and a sleeve 35 . The support platform 31 is placed on the ground, the support ring 32 is ring-shaped and the axis is horizontally arranged, and the bottom of the support ring 32 is welded on the support platform 31 .

[0046] refer to figure 2 , the bearing ring 33 is located at the two ends of the inner wall of the support ring 32, and one is fixedly connected respectively, the bearing ring 33 and the support ring 32 are arranged coaxially, there is a distance between...

Embodiment 2

[0078] refer to figure 1 , a method for using a drawing machine mold core 11 replacement device, its use steps are as follows:

[0079] S1, plate loading: several mold cores 11 are circumferentially bolted to the mounting plate 10 according to the sequence of use;

[0080] refer to Figure 5 , S2, position adjustment: the operator manually adjusts the offset lever 24 to the connection between the maximum deflection groove 201 and the reset groove 203, and makes the offset lever 24 touch the side wall at the end of the maximum deflection groove 201, and through the insertion rod The end of 63 is inserted into the corresponding insertion hole 212 to lock the mounting plate 10 tightly.

[0081] refer to Figure 5 and Figure 6 , S3, deflection: when replacing the mold core 11, the operator pulls the insertion rod 63 out of the insertion hole 212, and then rotates the mounting plate 10, the deflection rod 24 moves along the arc direction of the deflection groove 201, and passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com