Design method of anti-pollution air knife structure for welding laser lens

A laser lens and design method technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of fast splash speed, large size, easy to pollute the lens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

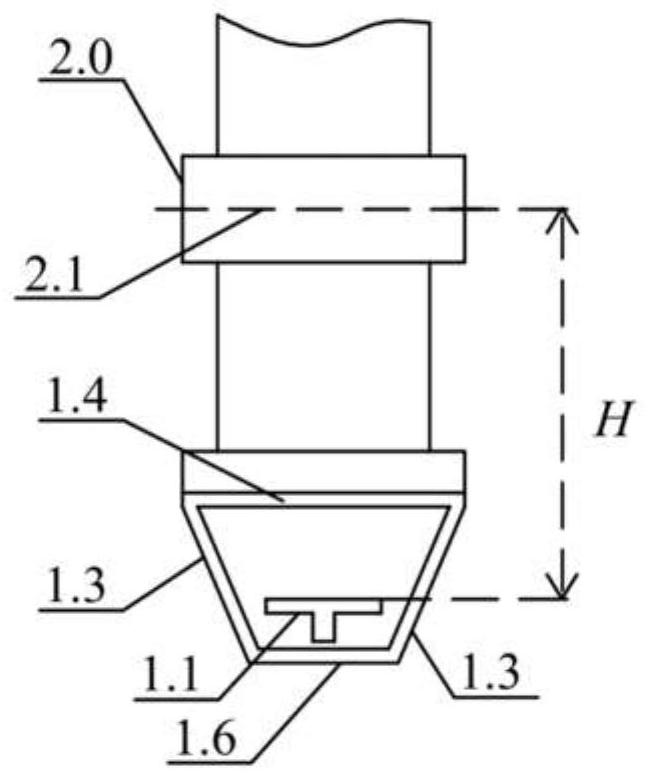

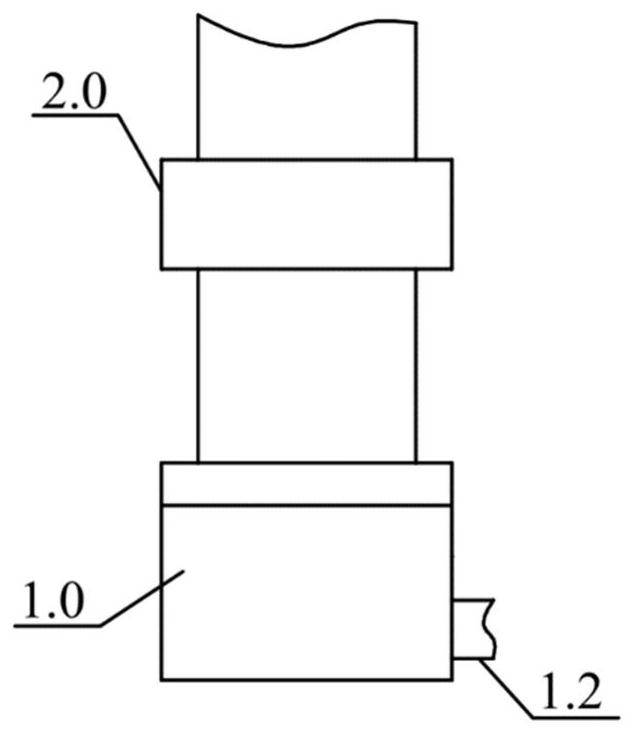

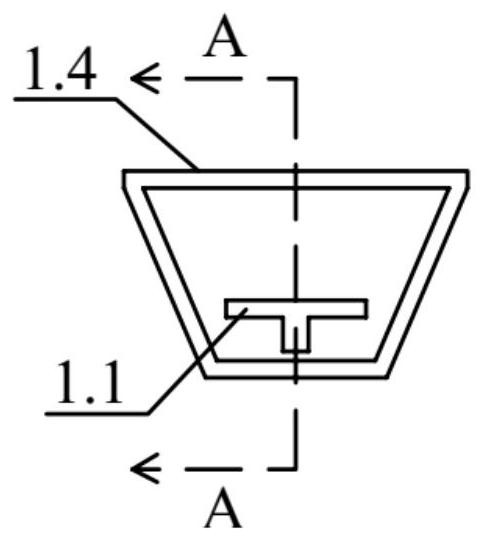

[0031] A design method for the anti-pollution air knife structure of a welding laser lens, comprising determining the installation position of the air knife main body 1.0 on the laser welding device, determining the position of the reference plane of the air knife outlet 1.1, designing the shape and size of the air knife outlet 1.1, It is characterized in that: the air knife outlet 1.1 is a T-shaped air outlet, the reference plane of the air knife outlet 1.1 is the plane where the top of the T-shaped air outlet is located, and the size of the T-shaped air outlet is based on the parameters of the laser lens and the air knife outlet 1.1 Design the distance H between the reference plane and the plane 2.1 where the laser focusing lens 2.0 is located, and the height h of the upper part of the T-shaped air outlet 1 , width w 1 and the height h of the lower part of the T-shaped air outlet 2 , width w 2 The following formula needs to be satisfied:

[0032]

[0033] h 1 ≥1mm

...

Embodiment 2

[0043] A design method for the anti-pollution air knife structure of welding laser lens, including determining the installation position of the main body of the air knife, determining the reference plane position of the air outlet of the air knife, designing the shape and size of the air outlet of the air knife, and opening the air knife outlet on the main body of the air knife , it is characterized in that: the air knife air outlet datum plane is the plane where the top of the air knife air outlet is located, the air knife air outlet is T-shaped, and the size of the T-shaped air outlet is based on the laser lens parameters and the air knife air outlet datum plane Design the distance H from the plane where the focusing lens is located, and the height h of the upper part of the T-shaped air outlet 1 , width w 1 and the height h of the lower part of the T-shaped air outlet 2 , width w 2 The following formula needs to be satisfied:

[0044]

[0045]

[0046] h 1 ≥1mm

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com