Full-automatic outer box cover assembling system of diaphragm gas meter

A membrane gas meter and assembly system technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing the production efficiency of enterprises, low degree of automation, low production efficiency, etc., to improve the production efficiency and automation of enterprises. The effect of high degree and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

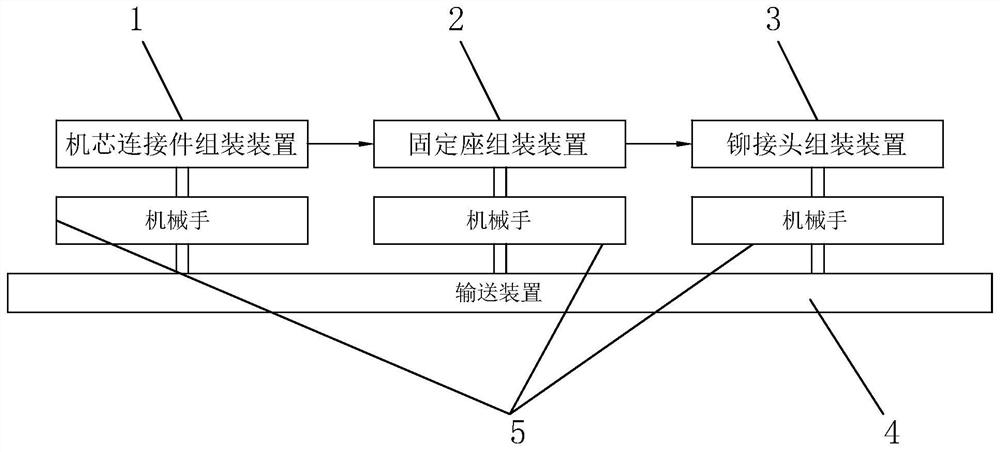

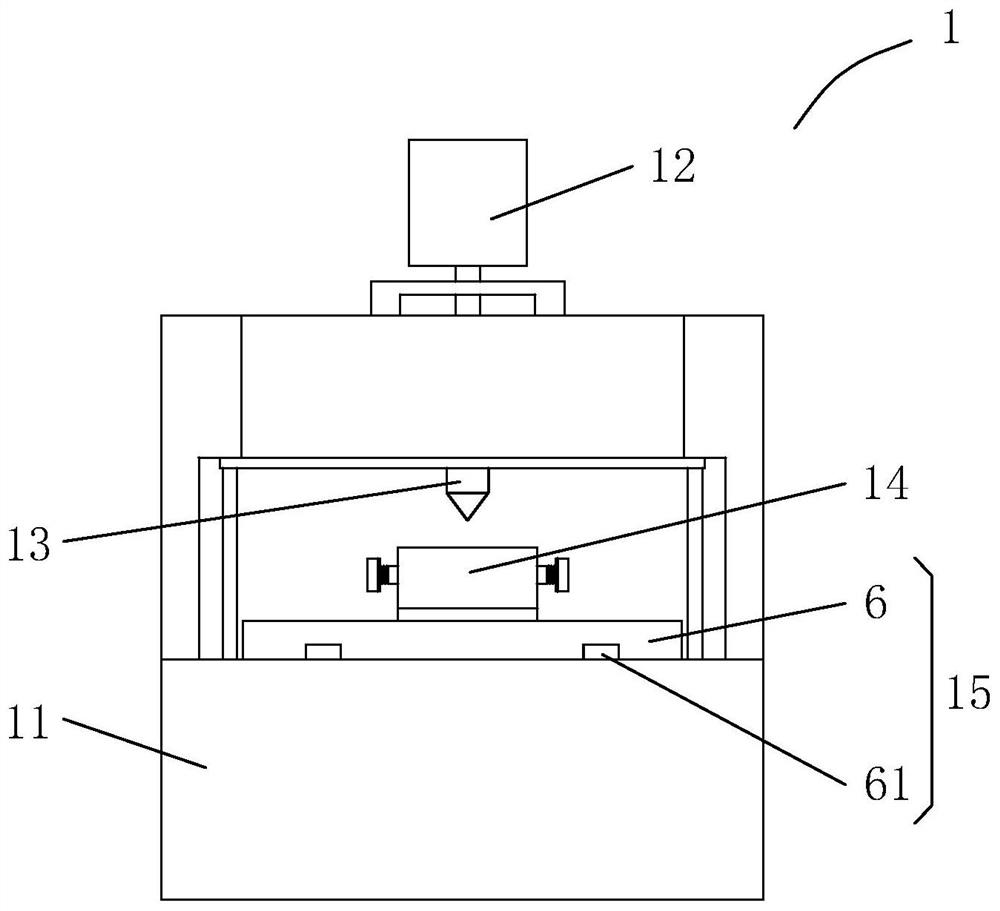

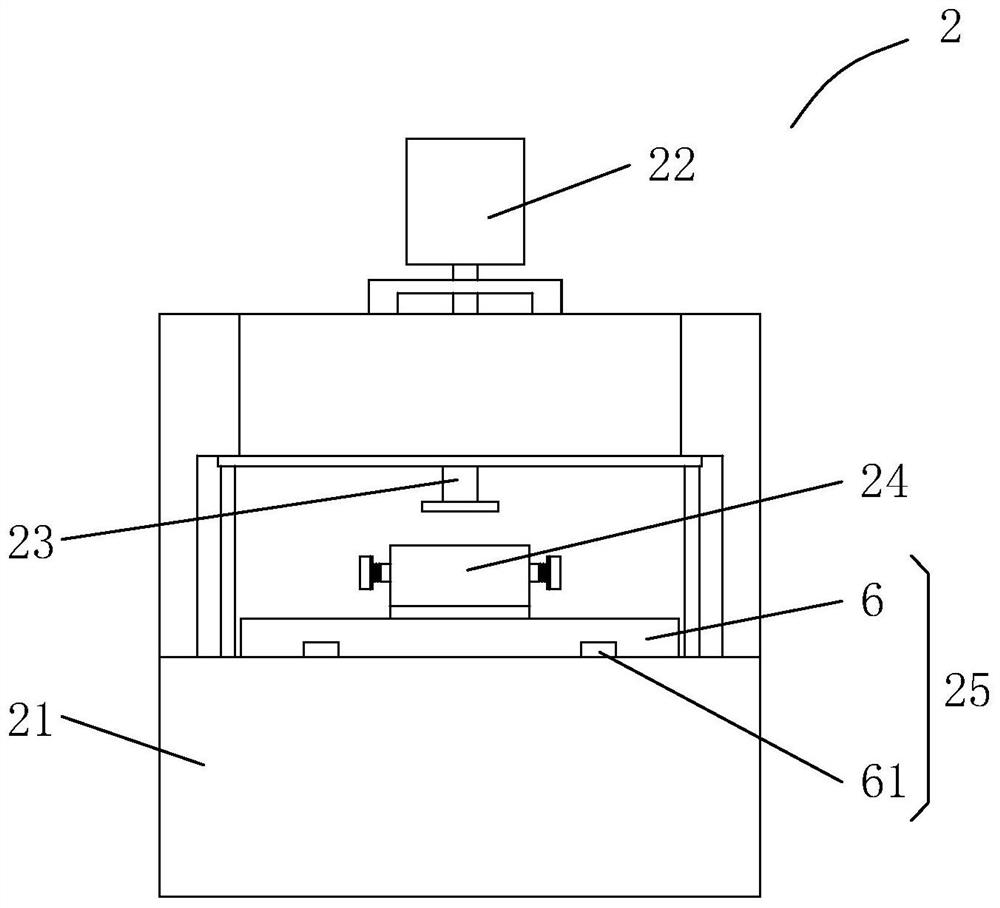

[0028] Such as figure 1 As shown, a fully automatic outer box cover assembly system for a membrane gas meter includes a line-up movement connector assembly device 1, a fixed seat assembly device 2, and a riveting head assembly device 3. The movement connection part assembly The device 1 is used to install the connecting piece of the movement on the membrane gas meter, the fixing seat assembly device 2 is used to install the fixing seat on the membrane gas meter, and the riveting head assembly device 3 is used to install the riveting head on the membrane gas meter. membrane gas meter.

[0029] It also includes a conveying device 4 arranged along the lengthwise direction of the core connector assembly device 1, the fixed seat assembly device 2, and the riveting head assembly device 3, and the conveying device 4 is used to sequentially transport the diaphragm gas meter to the core connector assembly device 1 , Fixing seat assembly device 2 and riveting head assembly device 3.

...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that: Figure 5 As shown, an abutting plate 72 is hinged on the end of the abutting telescopic rod 7 away from the assembly seat, and the side of the abutting plate 72 away from the abutting telescopic rod 7 is configured as a slope-shaped structure. The setting of the inclined-plane structure helps to realize the gradual abutment of the outer box cover, which not only reduces corner friction, but also further improves the placement stability of the outer box cover.

[0053] The specific implementation principle of the present invention is: when working, first the delivery device 4 transports the outer box cover to the movement connector assembly device 1, and is transferred to the movement connection part assembly device 1 by the manipulator 5, and the movement connection part Assembling device 1 assembles the connecting piece of the movement onto the outer box cover, and then the manipulator 5 transfers it to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com