A workshop goods grabbing manipulator

A technology for grasping manipulators and goods, applied in the field of manipulators, can solve problems such as high use limitations and reduced production efficiency, and achieve the effects of high safety, increased clamping distance, and easy clamping of goods of different specifications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

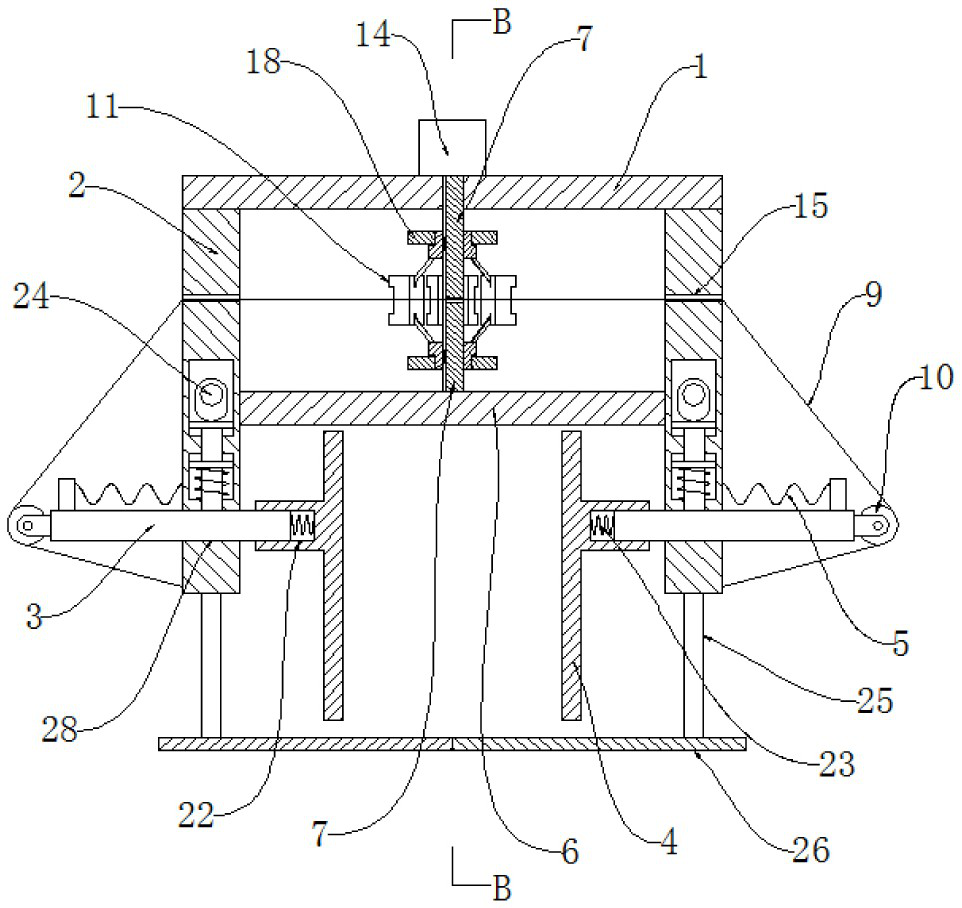

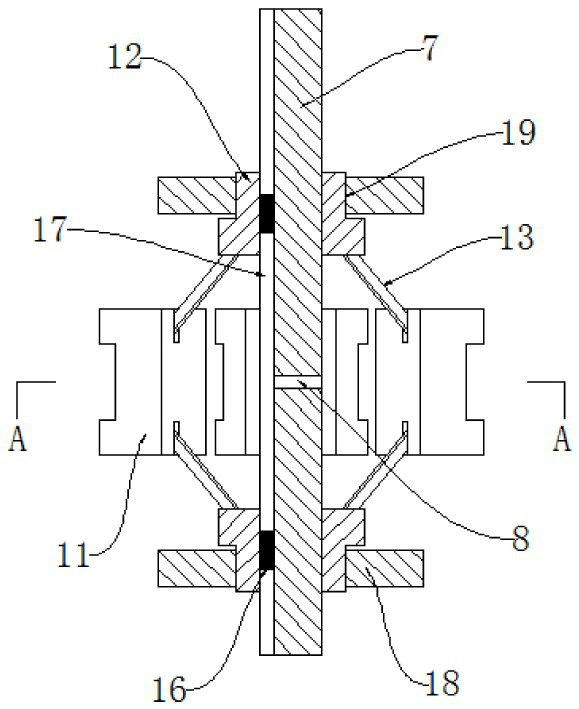

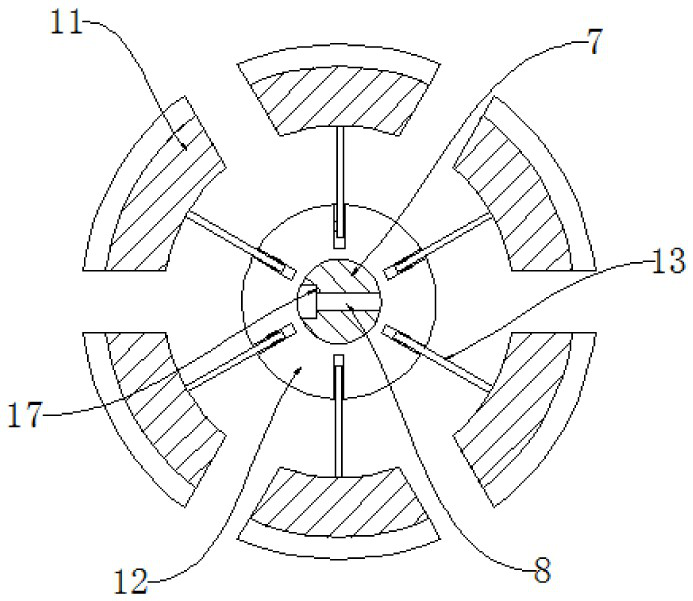

[0027] Such as Figure 1 to Figure 8 As shown, a workshop cargo grabbing manipulator includes a first mounting plate 1, side plates 2 are fixedly installed at the left and right ends of the bottom of the first mounting plate 1, and the two side plates 2 slide left and right respectively. A clamping arm 3 is installed, and one end of the clamping arm 3 is elastically connected with a clamping head 4 located between the two side plates 2, and one end of the clamping arm 3 away from the clamping head 4 is connected to the clamping head 4. A return spring 5 is connected between the corresponding side plates 2; a second mounting plate 6 above the clamping head 4 is fixedly installed between the two side plates 2, and the first mounting plate 1 A vertical shaft 7 is installed in rotation with the second mounting plate 6, and a horizontally extending threading hole 8 is provided on the vertical shaft 7, and a steel wire rope 9 is arranged in the threading hole 8, and the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com