Method for modifying T-beam prefabricated pedestal

A technology of prefabricated tables and pedestals, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of increasing construction engineering volume, construction period time, and economic loss, so as to reduce time and economic investment, simplify the transformation method, and shorten the construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

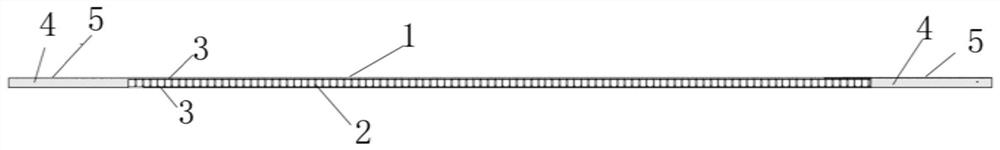

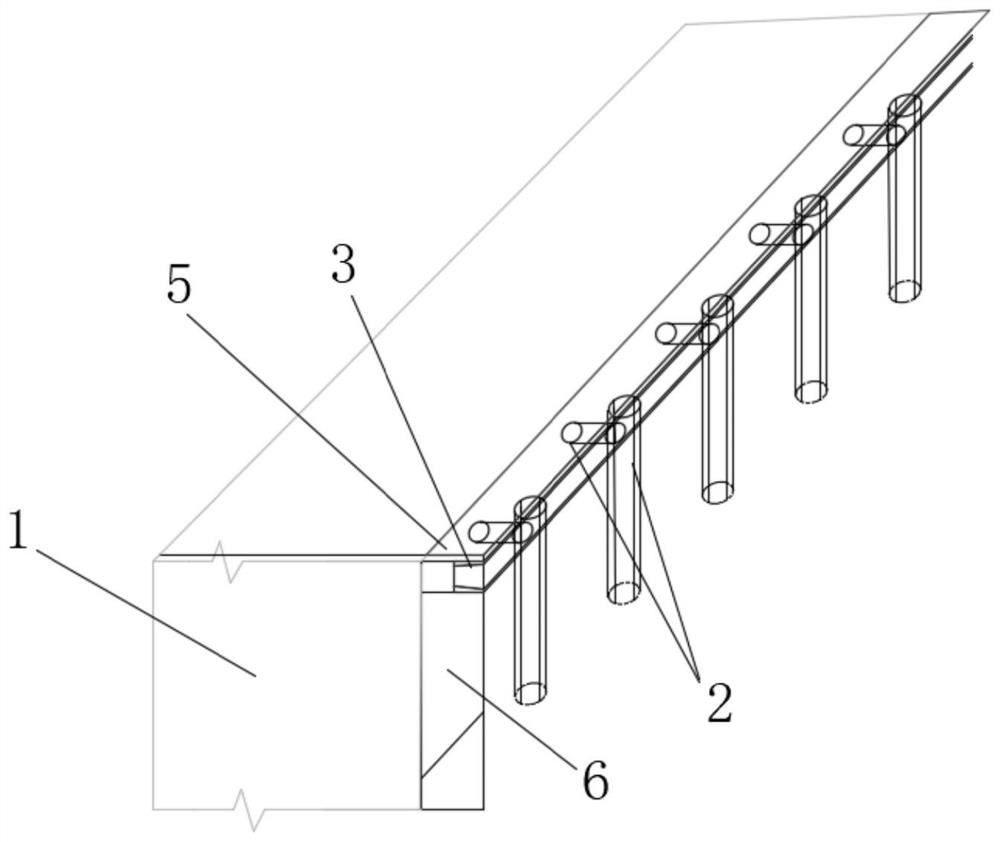

[0029] see Figure 1-2 , the present application provides a method for reforming a T-beam prefabricated pedestal, calculating the length numerical difference M and the width numerical difference N between the original T-beam prefabricated pedestal and the target T-beam prefabricated pedestal 1 that needs to be reformed, and calculating the numerical difference M / Two extended sections 4 of length 2 are added to both ends of the original T-beam prefabricated pedestal 1, and two widened sections 6 with a numerical difference of N / 2 length are added to both sides of the original T-beam prefabricated pedestal.

[0030] For example, a simple construction method for changing a 30m prefabricated T-beam pedestal to a 40m prefabricated T-beam pedestal. Since the size of the 30m prefabricated T-beam pedestal is 31m×50cm×40cm (length×width×height), the size of the 40m prefabricated T-beam pedestal is 41m×60cm×40cm (length×width×height). It consists of two parts: 1. 4 parts of the extens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com