Rear-drive series hybrid power driving system

A power-driven, series-mixed technology, which is applied to the layout of multiple different prime movers of hybrid vehicles, power plants, and general-purpose power plants, can solve problems such as accelerated fuel consumption, high fuel consumption, and accelerated power consumption, and achieve reduction Effects of loss, low emission, and fuel consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

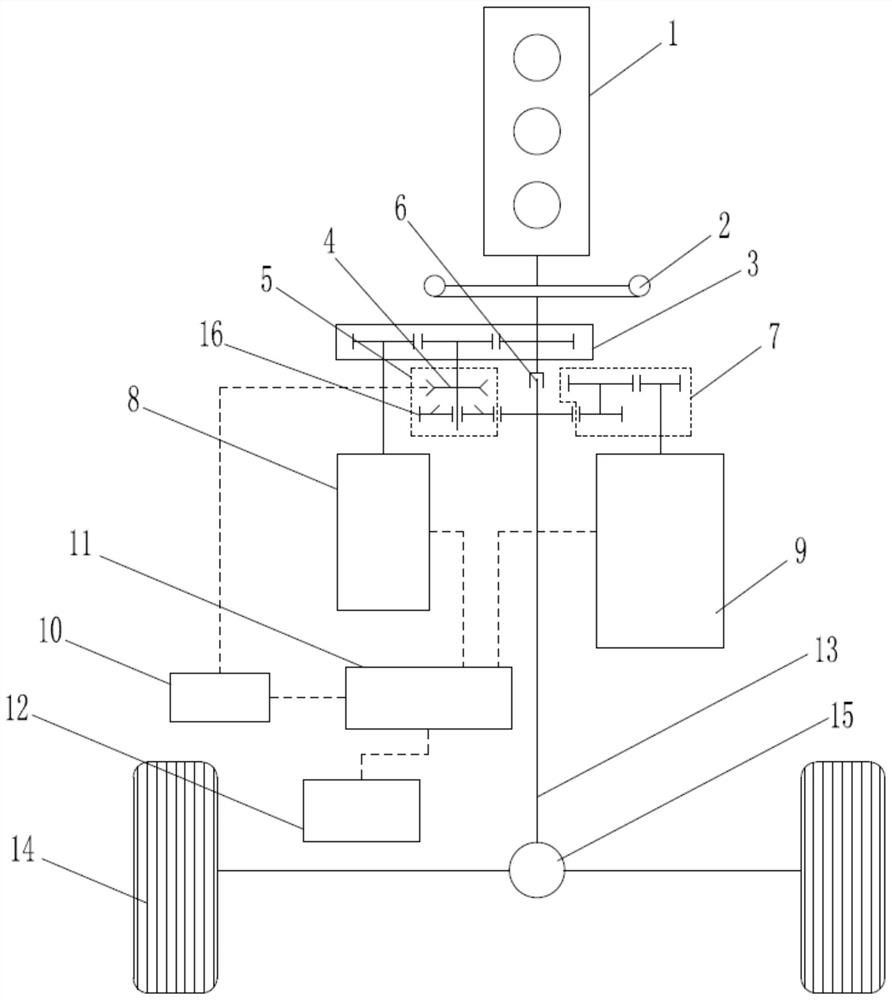

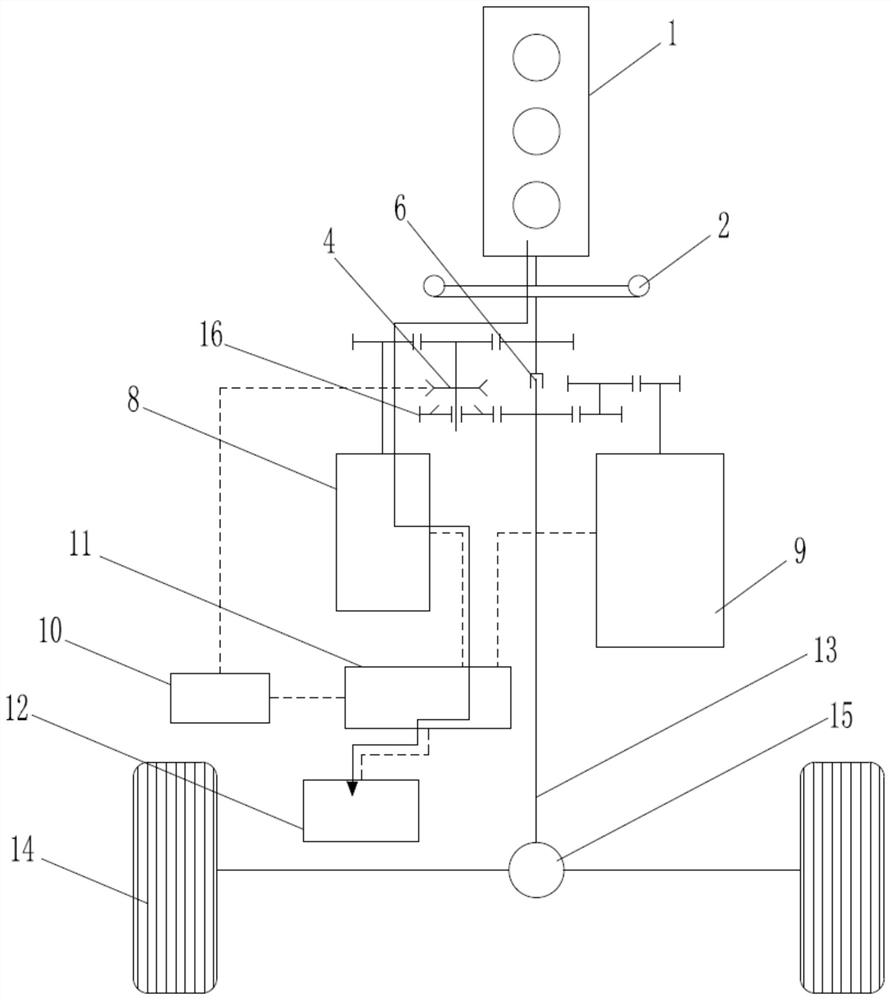

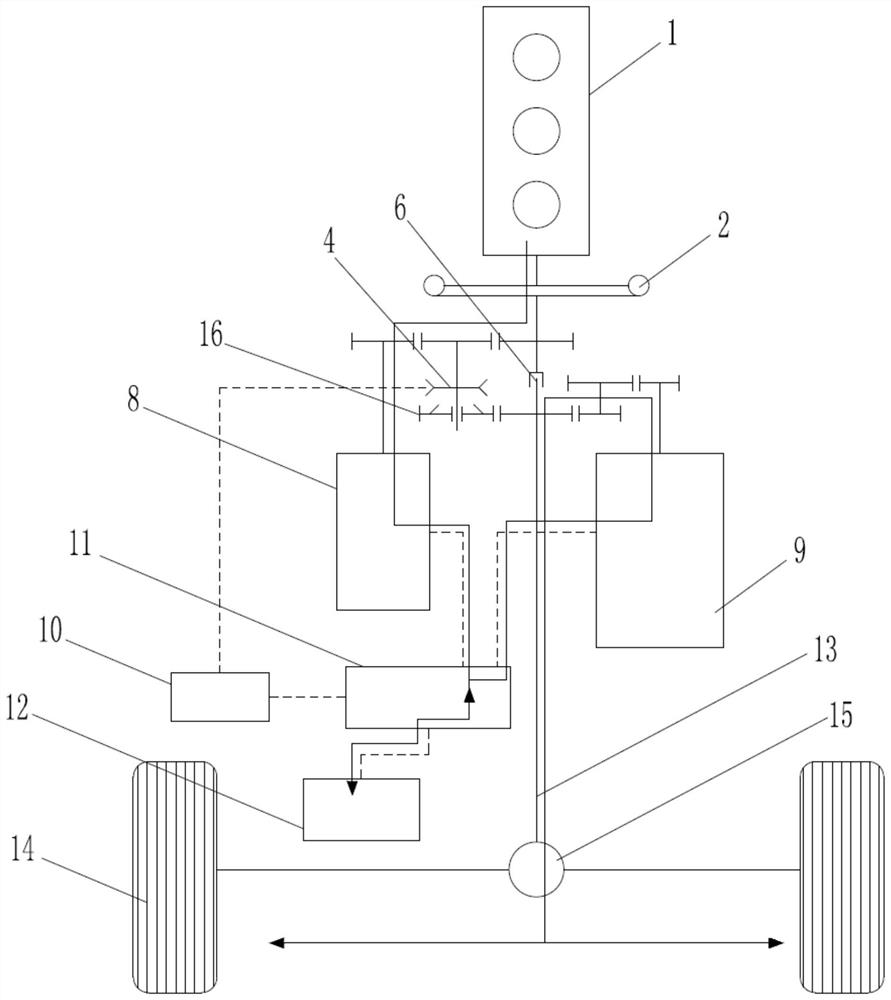

[0035] The specific embodiment of the present invention is as figure 1 As shown, a rear-drive serial hybrid drive system includes an engine 1, a speed increaser 3, a generator 8, a motor controller 11, a drive motor 9, a speed reducer 7, a drive shaft 13, a wheel shaft and a vehicle connected in sequence. 14 rear wheels.

[0036] Wherein, the booster 3 includes a booster input gear connected to the output end of the engine 1 , a booster intermediate gear and a booster output gear connected to the input end of the generator 8 . The input gear of the speed increaser, the intermediate gear of the speed increaser and the output gear of the speed increaser are engaged in transmission connection in sequence. The shaft center of the intermediate gear of the speed increaser is also intermittently connected with the input end of the transmission shaft 13 through the direct drive shaft system 5 . The motor controller 11 is also connected with the battery 12 and the vehicle controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com