Antioxidant gradient crosslinked polyethylene material and preparation method thereof

A technology of cross-linked polyethylene and polyethylene, applied in the field of polymer materials, can solve the problems of difficult to achieve a good balance between material cross-linking degree, oxidation resistance and mechanical properties, achieve excellent oxidation resistance, improve service life, The effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

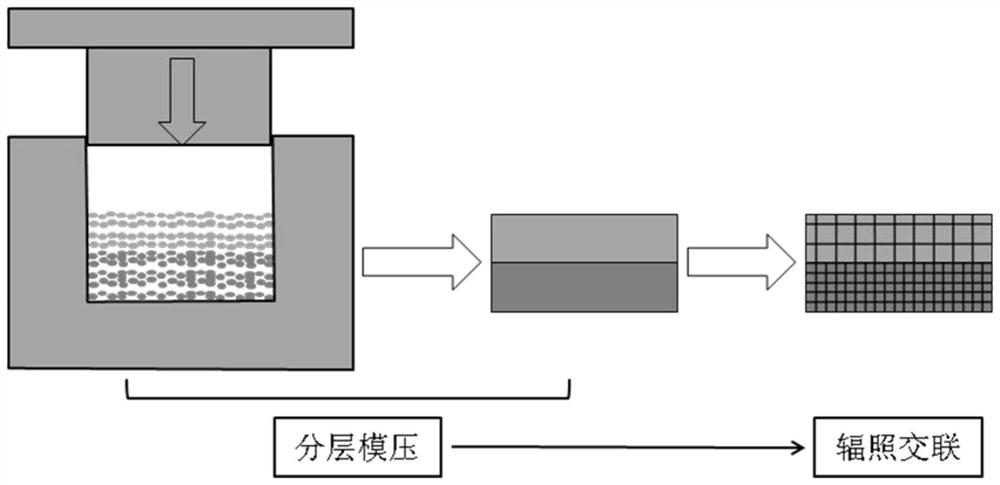

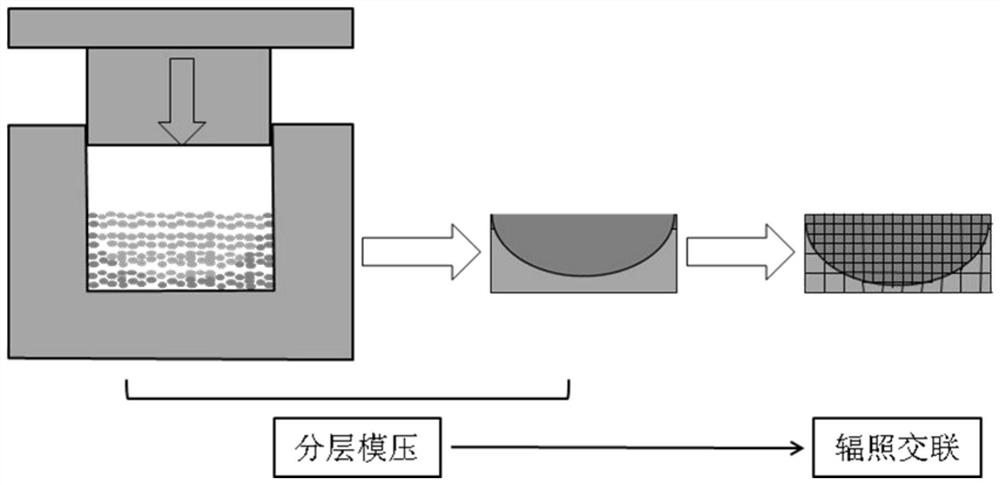

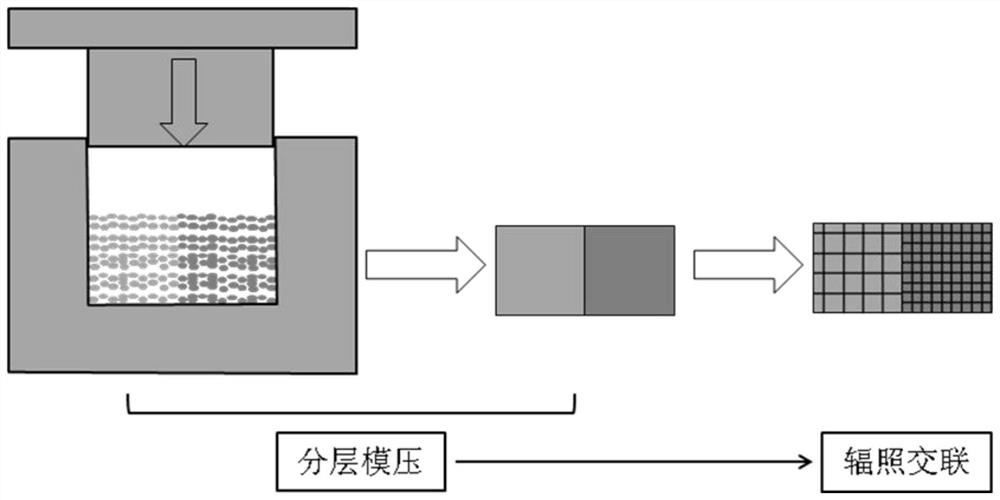

[0040] The present invention also provides a preparation method of an anti-oxidation gradient cross-linked polyethylene material, comprising the following steps:

[0041] a) preparing a first mixed powder and a second mixed powder; the first mixed powder is a mixed powder of polyethylene and vitamin E, and the second mixed powder is a mixed powder of polyethylene and gallic acid;

[0042] b) respectively filling the first mixed powder and the second mixed powder into the mould, and the two mixed powders are not mixed; after filling, the first mixed powder layer and the second mixed powder layer are formed in the mold, and the two mixed There is an interface between the powder layers;

[0043] c) sintering the mixed powder loaded into the mold, and then demoulding to obtain a blank to be irradiated;

[0044] d) irradiating the blank to be irradiated with electron beams to obtain an anti-oxidation gradient cross-linked polyethylene material.

[0045] In the preparation method ...

Embodiment 1

[0055] Step (1): Add 100 grams of vitamin E to 1 liter of acetone solvent and mix evenly, then add 100 kilograms of polyethylene resin powder, mix thoroughly, and dry at 60°C for 14 days to obtain the first mixed powder; add 100 grams of gallic acid Mix evenly in 1 liter of acetone solvent, then add 100 kg of polyethylene resin powder, mix thoroughly, and dry at 60°C for 14 days to obtain the second mixed powder;

[0056] Step (2): spread the first mixed powder in the mold for compaction, the amount of powder added accounts for about 1 / 3 of the mold volume, and then spread the same volume of the second mixed powder on the upper layer of the first mixed powder;

[0057] Step (3): Place the powder-containing mold on the hot plate of a flat vulcanizer, heat it to 240°C, pressurize it to 20MPa, keep the temperature and pressure constant for 2 hours, so that the mixture powder is sintered into a block; then cool down to 120°C, keep the pressure constant for 1.5 hours, then lower to...

Embodiment 2

[0060] Step (1): Add 100 grams of vitamin E to 1 liter of acetone solvent and mix evenly, then add 100 kilograms of polyethylene resin powder, mix thoroughly, and dry at 60°C for 14 days to obtain the first mixed powder; add 100 grams of gallic acid Mix evenly in 1 liter of acetone solvent, then add 100 kg of polyethylene resin powder, mix thoroughly, and dry at 60°C for 14 days to obtain the second mixed powder;

[0061] Step (2): spread the first mixed powder in the mold for compaction, the amount of powder added accounts for about 1 / 3 of the mold volume, and then spread the same volume of the second mixed powder on the upper layer of the first mixed powder;

[0062] Step (3): Place the powder-containing mold on the hot plate of a flat vulcanizer, heat it to 240°C, pressurize it to 20MPa, keep the temperature and pressure constant for 2 hours, so that the mixture powder is sintered into a block; then cool down to 120°C, keep the pressure constant for 1.5 hours, then lower to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com