Ceramic tile soaking device capable of avoiding hollowing

A ceramic tile and hollowing technology, which is applied in the direction of construction and building construction, and can solve problems such as affecting the construction progress, poor bonding, and gaps in the connection between tiles and cement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0027] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

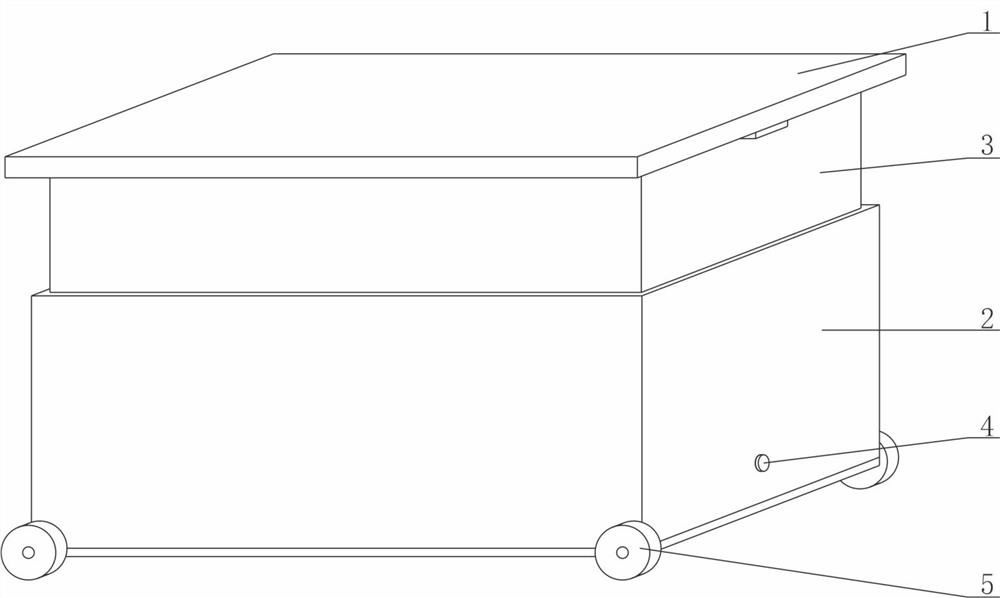

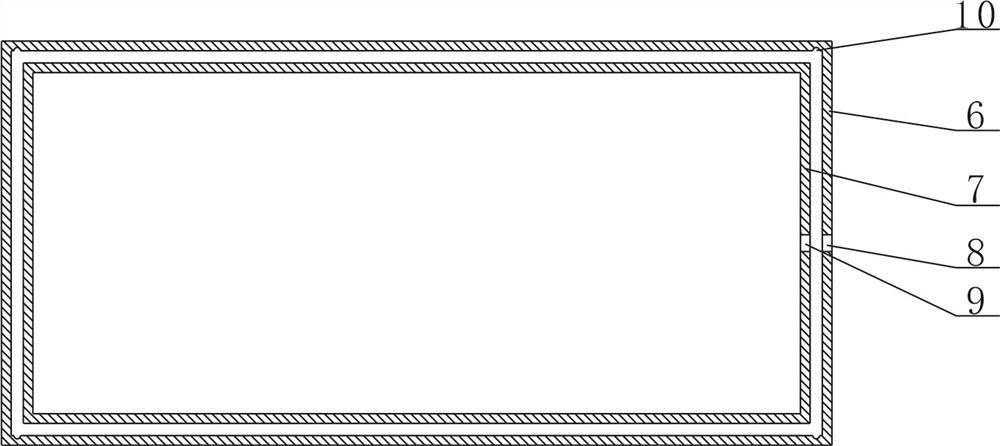

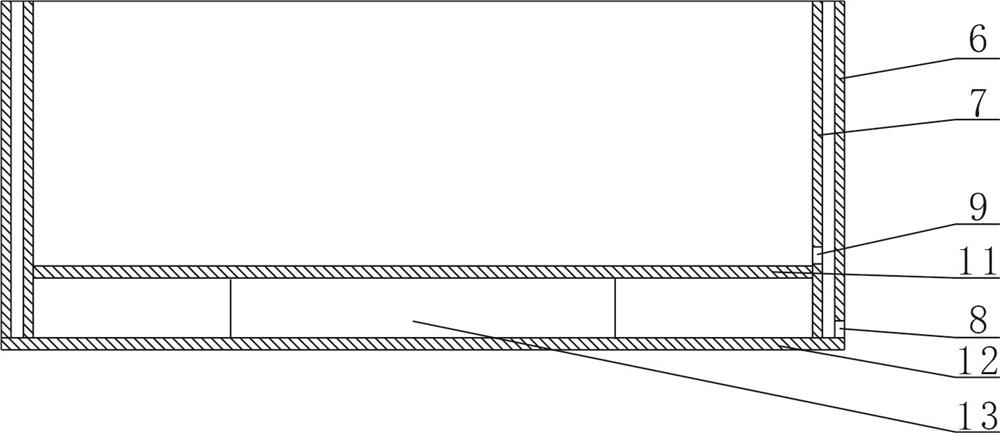

[0028] combined with Figure 1~9 The ceramic tile soaking device that avoids hollowing includes a box body 2, an extension device, a cover plate 1, a fixing plate 15, a support rod 17, a first buffer portion and a second buffer portion, and the box body 2 is provided with an extension device, a fixed plate 15 and a first buffer portion, the fixed plate 15 is provided with a support rod 17, the extension device is provided with a cover plate 1, and the cover plate 1 is provided with a second buffer portion, and the box body 2 is composed of a bottom plate 12, a connecting plate 11. The vibrator 13, the first housing 6, the second housing 7, the support block 14, the wheel 5 and the sealing plug 4 are formed, and the bottom plate 12 is provided with the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com