Glue-pouring waterproof axial flow fan convenient to produce

An axial flow fan and waterproof technology, which is applied to axial flow pumps, parts of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problems of reducing wind noise and poor reliability of fans, and achieve the goal of reducing wind Noise, optimized control drive control program, simple appearance and structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

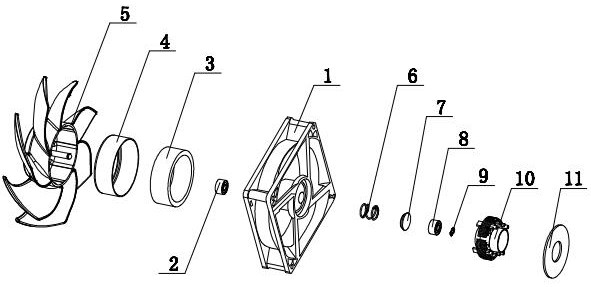

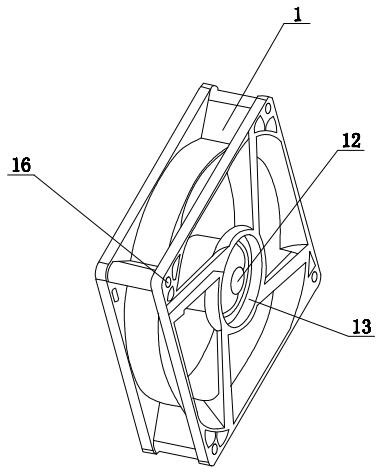

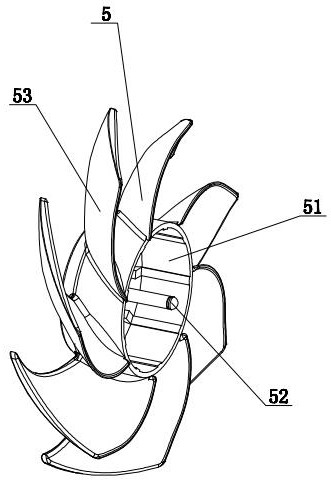

[0018] see Figure 1 to Figure 4 As shown, the technical solution adopted in this specific embodiment is: it includes a machine frame body 1, a first ball bearing 2, a rubber magnetic strip 3, an iron shell 4, a fan blade body 5, a stainless steel spring 6, a waterproof cover 7, a second Ball bearing 8, stainless steel circlip 9, silicon steel sheet 10, PCBA board 11, the shape of the machine frame body 1 is a square structure, and the center of the machine frame body 1 is provided with a fixing hole 12 and a fixing counterbore 13 , the fixed hole 12 is connected with the fixed counterbore 13 to form a T-shaped counterbore, the center of the fan blade body 5 is provided with a relief counterbore 51, and the said relief counterbore 51 is provided with a fixed shaft 52, the centers of the rubber magnetic strip 3 and the iron shell 4 are provided with through holes, the iron shell 4 is installed in the counterbore 51, and the rubber magnetic strip 3 is installed in the iron shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com