Detection device for rack rail of rack rail railway

A detection device and rack technology, which can be applied to measurement devices, mechanical measurement devices, and mechanical devices, etc., can solve the problems of lack of detection of rack and track installation position parameters, and achieve a simple structure, ensure accuracy, and ensure safe operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

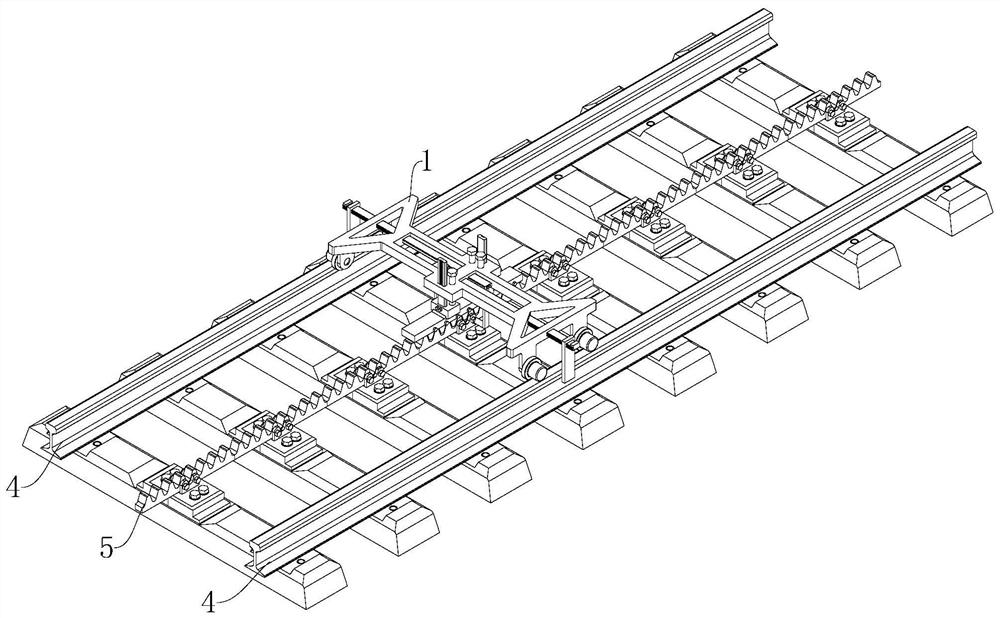

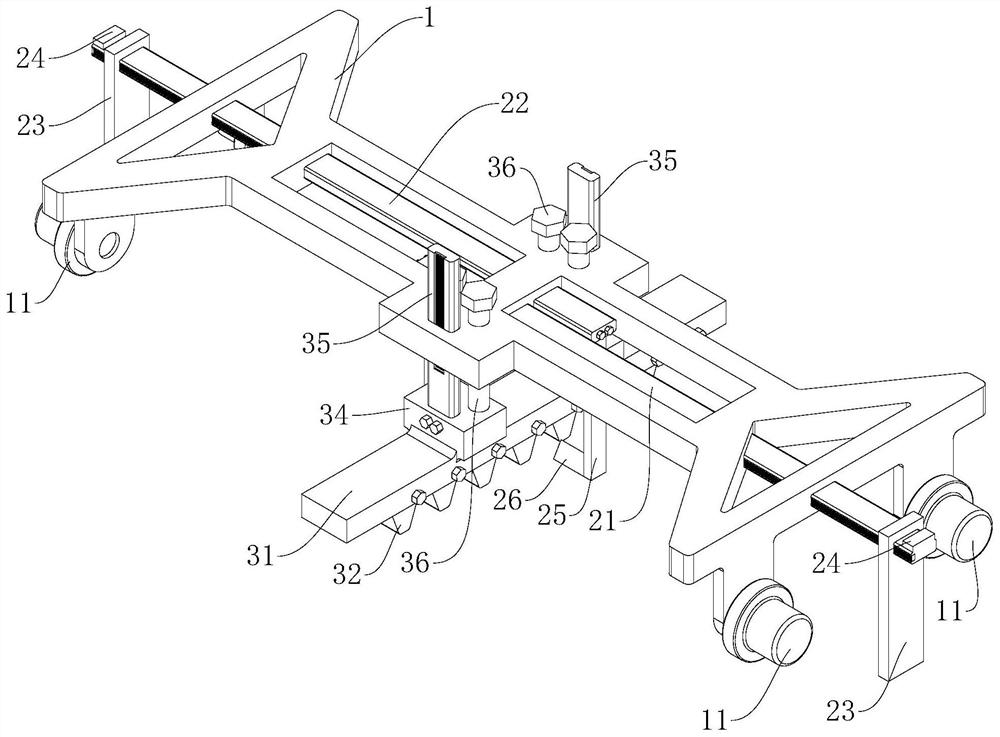

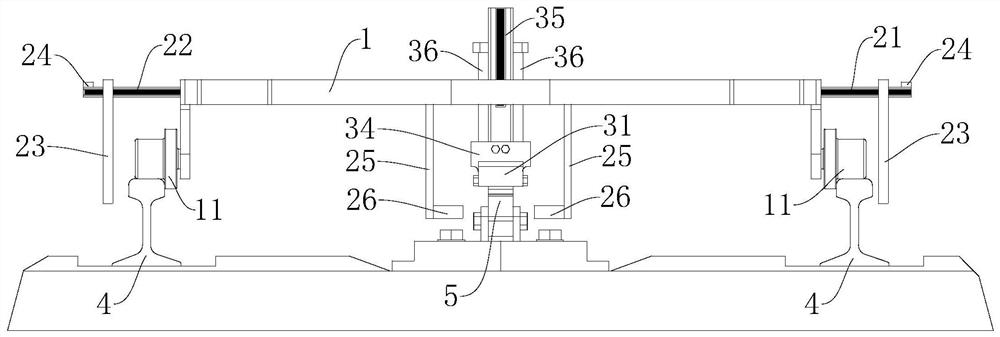

[0036] A detection device for rack railway cogs, such as Figure 1-Figure 6 As shown, it includes a frame 1, a level measurement module 2, an elevation measurement module 3 and other accessory parts. The detected object is mainly the rack 5 that has been installed on the rack track circuit.

[0037] Such as Figure 2-Figure 5 , the horizontal measurement module 2 includes two horizontal scales: a first horizontal scale 21 and a second horizontal scale 22, the first horizontal scale 21 spans the cog rail 5 and the side rail 4, and the second horizontal scale 22 spans the cog rail 5 and On the other side rail 4, the first horizontal scale 21 and the second horizontal scale 22 are symmetrically arranged on the frame 1 with respect to the center point; A through hole adapted to the cross-sectional size of the corresponding horizontal scale is arranged horizontally for the horizontal scale to penetrate through the frame 1 horizontally; the two horizontal scales have the same stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com