Small-displacement pre-thrust mechanism

A small displacement, thrust technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

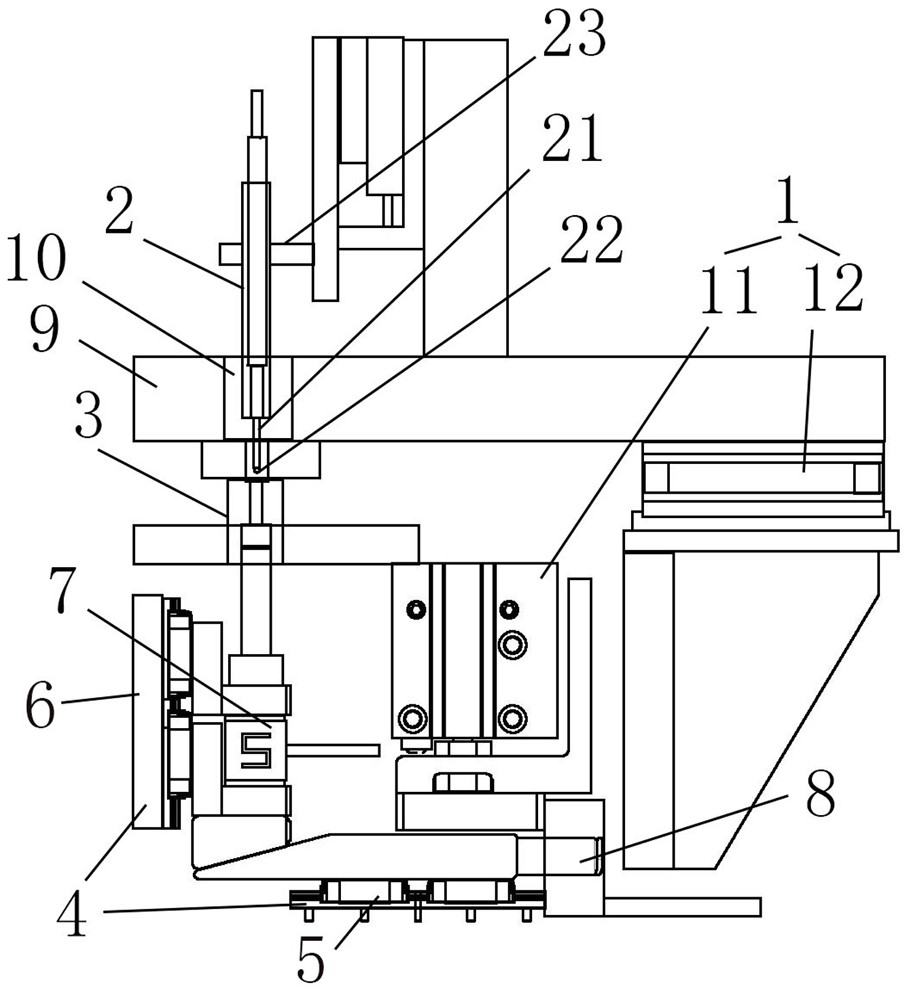

[0046] see figure 1 with figure 2 , a small displacement pre-thrust mechanism, including a driving assembly 1, a measuring device 2, a product fixing assembly 3 and a moving device 4;

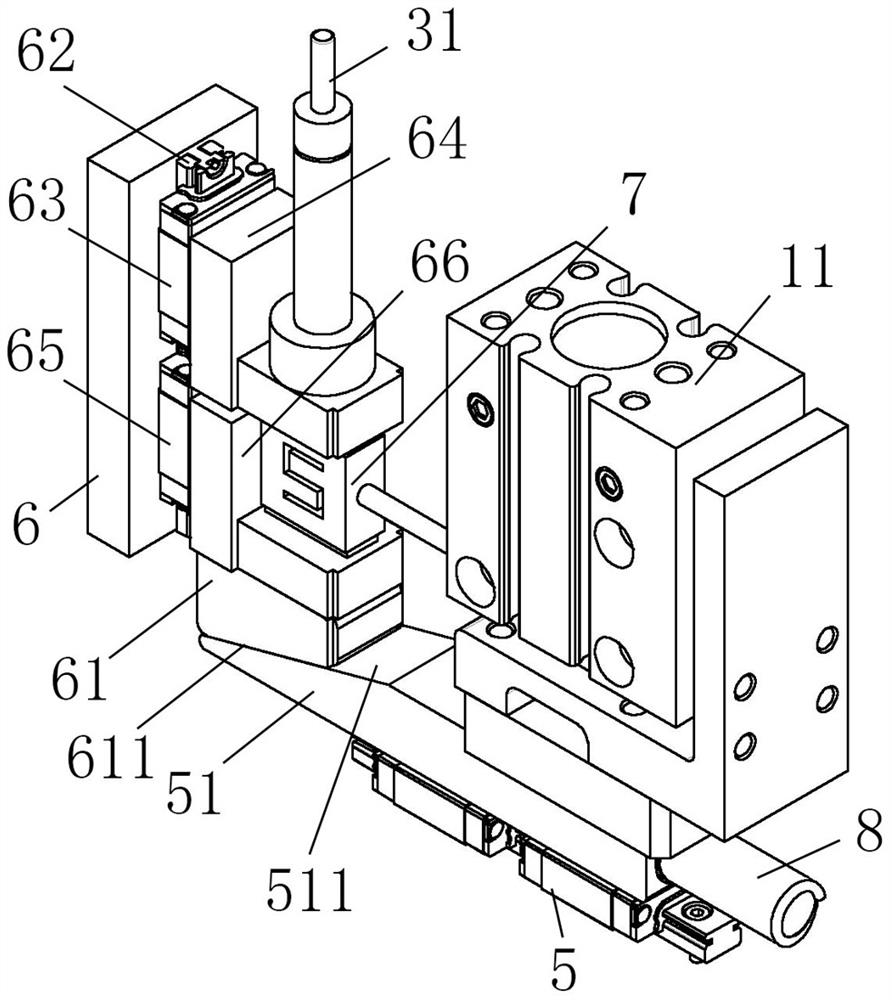

[0047] The moving device 4 includes an X-axis moving device 5, a push block 51 arranged on the X-axis moving device 5, a Z-axis moving device 6, and a reverse thrust block 61 arranged on the Z-axis moving device 6;

[0048] The push block 51 is provided with a first slope 511, and the reverse thrust block 61 is provided with a second slope 611 in contact with the first slope 511;

[0049] The Z-axis moving device 61 is provided with a pressure sensor 7;

[0050] The product fixing assembly 3 is arranged between the Z-axis moving device 6 and the measuring device 2;

[0051] The measuring device 2 includes a measuring probe 21, and a probe 22 for monitoring product displacement data is arranged at the bottom of the measuring probe 21.

[0052] Further, the drive assembly 1 includes a stop c...

Embodiment 2

[0085] The small displacement pre-thrust mechanism described in this embodiment is used to measure the displacement between the first product: metal sheet and the second product: glass sheet.

[0086] This embodiment is carried out on the basis of the above embodiments, and the similarities with the above embodiments will not be repeated.

[0087] In this embodiment, the accuracy of the linear motor 12 is ±0.005 mm, the accuracy of the X-axis moving device 5 and the Z-axis moving device 6 is ±0.02 mm, and the pressure sensor 7 is within a displacement of 0.001 mm. The corresponding pressure is 17g.

[0088] Further, the included angle formed between the first inclined surface 511 on the push block 51 and the horizontal plane is 15°, and the included angle formed by the second inclined surface 611 on the reverse thrust block 61 and the horizontal plane is 75°.

[0089] First, the anti-thrust block 61 in the device is removed, the linear motor 12 pushes the buffer spring 8 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com