Steel laboratory data processing method and system

A data processing system and data processing technology, applied in the field of steelmaking, can solve the problems of nearly 22 hours of time-consuming, low inspection efficiency, and simultaneous individual operation, so as to improve efficiency, reduce resource consumption pressure, and ensure compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

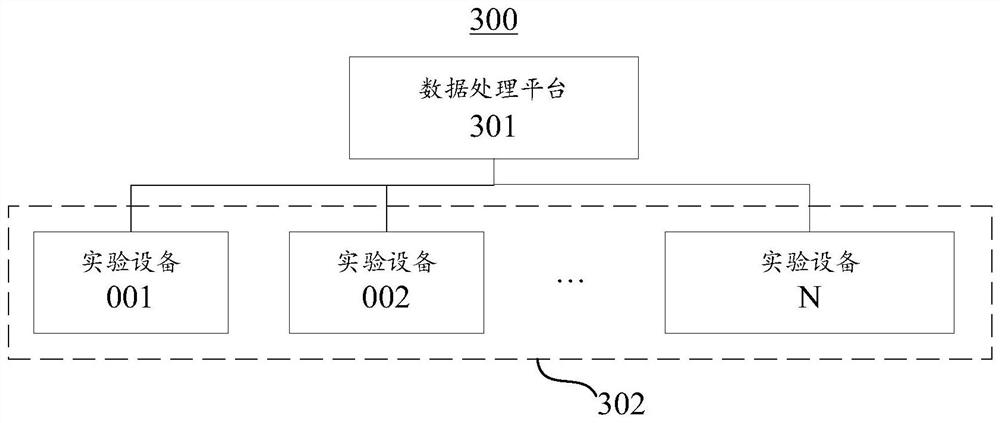

[0028] See figure 1 , shows a schematic structural diagram of a steel laboratory data processing system 300 provided by the first embodiment of the present invention; the system mainly includes: a data processing platform 301 and experimental equipment 302, and the experimental equipment 302 and the data processing platform 301 are connected in communication.

[0029] This embodiment is mainly used in iron and steel enterprises. In general large-scale iron and steel enterprises, there are hundreds of related test equipment and instruments, and each instrument has a variety of uses and interface forms. The system of this embodiment can solve the current steel and iron problems. The complex test data of the enterprise can be effectively uploaded to avoid omissions or upload errors. Experimental equipment 302 is equipment for testing, such as tensile machines, impact machines, spectrometers, etc., and also includes smelting analysis related equipment, hardness testing related equ...

no. 2 example

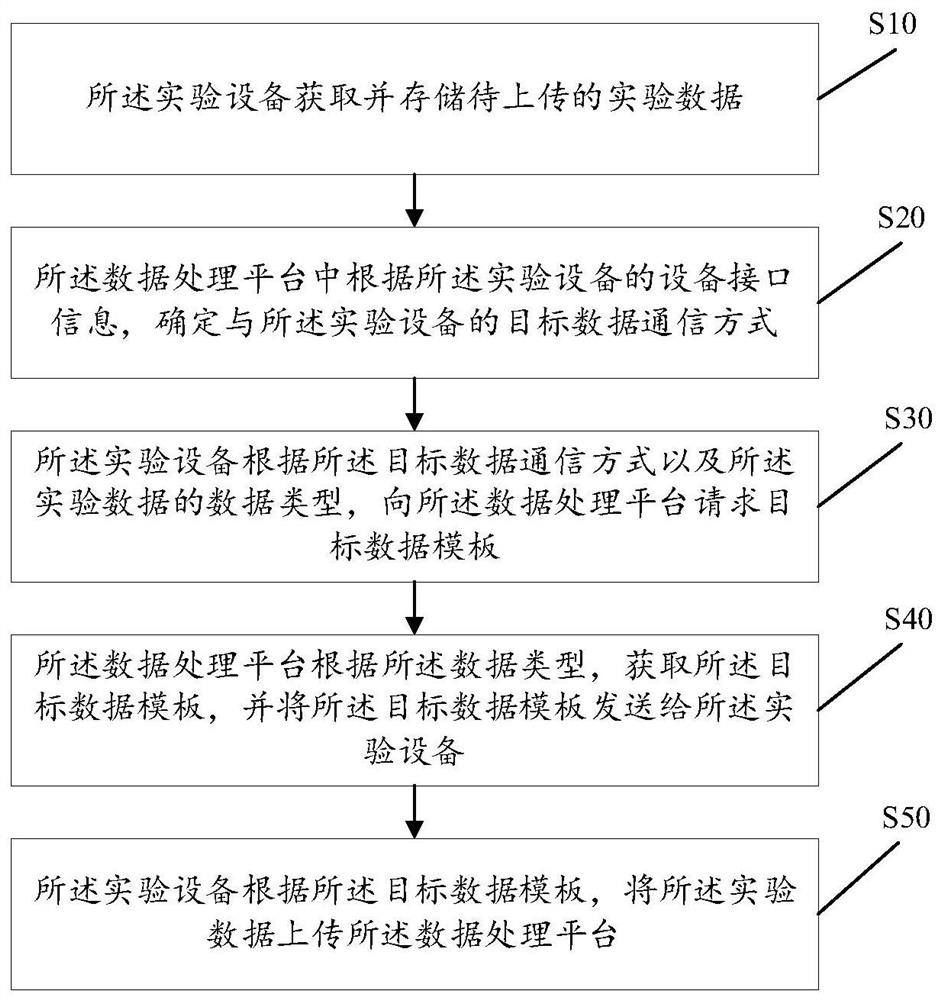

[0050] Based on the same inventive concept, the second embodiment of the present invention provides a method for processing data in a steel laboratory. This method can be applied to the system in the first embodiment above, and the method includes:

[0051] Step S10: the experimental equipment acquires and stores experimental data to be uploaded;

[0052] Step S20: The data processing platform determines the target data communication mode with the experimental equipment according to the equipment interface information of the experimental equipment;

[0053] Step S30: The experimental device requests a target data template from the data processing platform according to the target data communication method and the data type of the experimental data;

[0054] Step S40: the data processing platform acquires the target data template according to the data type, and sends the target data template to the experimental equipment;

[0055] Step S50: the experimental equipment uploads t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com