Equipment fault automatic identification method and system

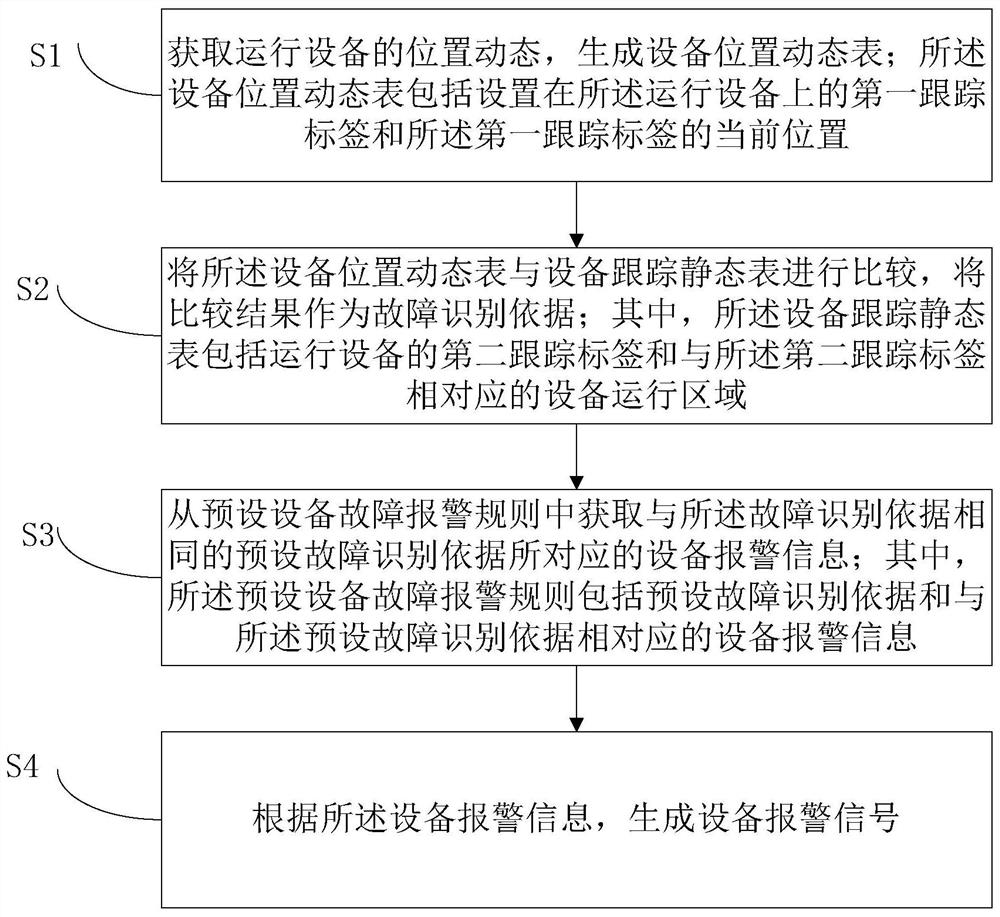

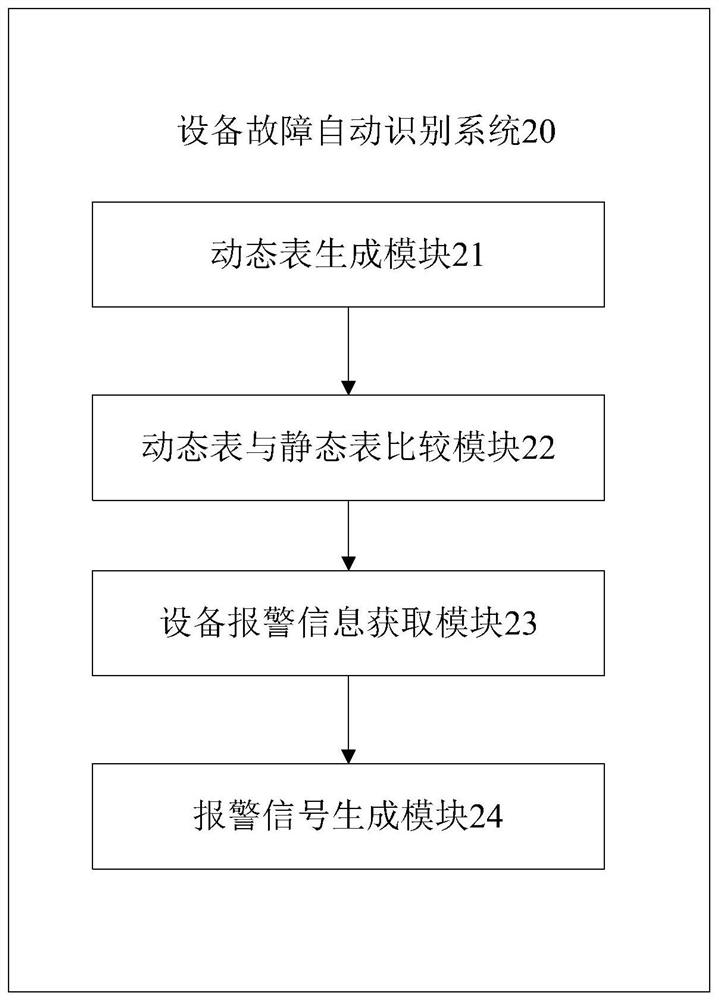

A technology for fault identification and equipment faults, which is applied in special data processing applications, instruments, and other database retrievals, etc., can solve problems such as failure to ensure tracking system fault self-inspection and stable and reliable operation, and failure to find faults in operating equipment in time, so as to improve Troubleshooting efficiency, saving troubleshooting time, and ensuring the effect of troubleshooting self-checking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] Taking the equipment in the continuous casting area as an example, the casting machine is a square blank co-casting machine, a total of 8 streams, and three draws per stream.

[0129] First, establish a device tracking static table, mainly tracking the tracking of the crystallizer and the pulling machine, including 8 crystalluses, 8 sets of wires, 8 sets of offline, one-to-use, backup crystalline general situation The crystallizer maintenance zone; 32 of the pull-up machine, where 24 lines are used, each of which is a pull-up machine, and the standby pull-up machine is in the maintenance area.

[0130] The tracking properties of each running device (all of this embodiment include all crystallizers and all pull-ups) include device identification and second tracking tags, including other tracking properties, such as the number of times, the number of maintenance, and device types. Device status, associated device, and the like. In this example, the apparatus of the crystalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com