Method and device for determining production cycle of commodity, and storage medium

A production cycle and commodity technology, applied in business, data processing applications, instruments, etc., can solve problems such as inaccurate production cycle, production cycle error, disputes, etc., and achieve the effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

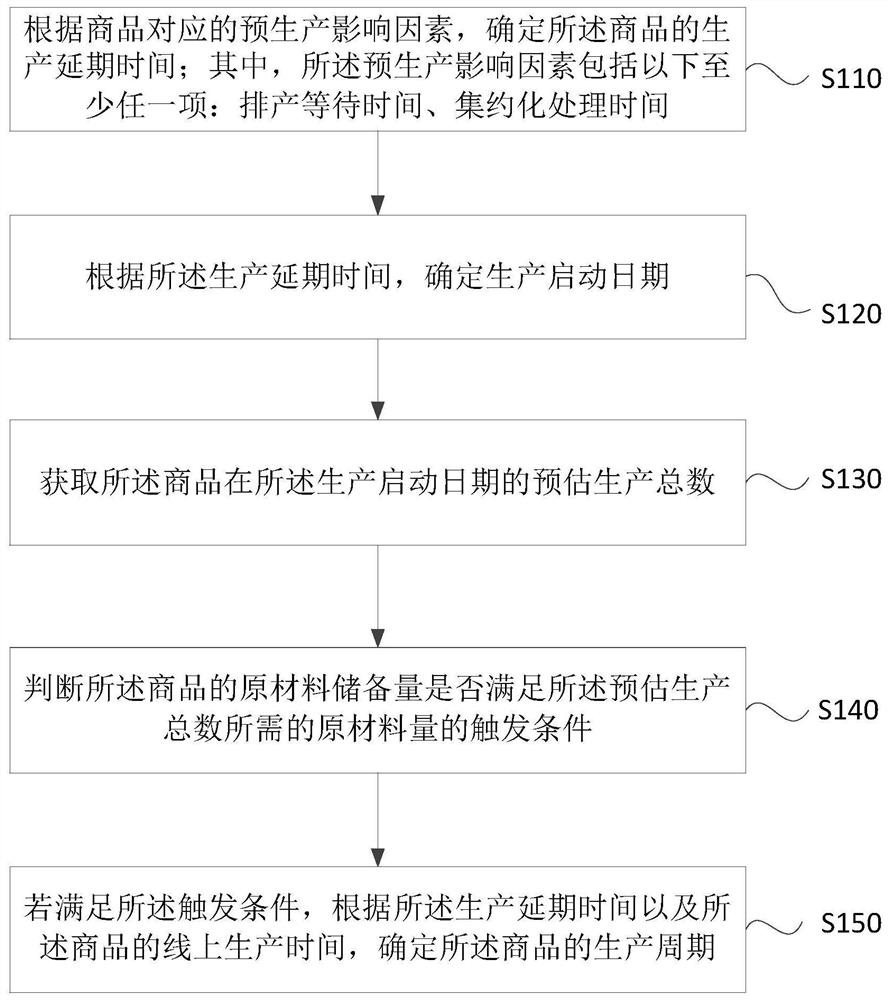

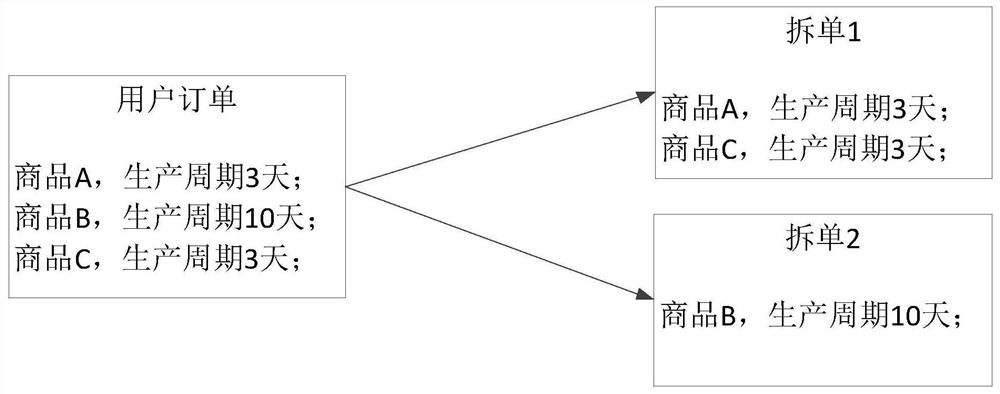

[0036] Figure 1A It is a flow chart of a method for determining the production cycle of a commodity provided by Embodiment 1 of the present invention. This embodiment is applicable to determining the production cycle of a commodity in the C2M mode. The method can be determined by the commodity in the embodiment of the present invention The production cycle determination device can be implemented, the device can be implemented by software and / or hardware, and integrated in electronic equipment (such as terminal equipment, network equipment), typically, can be integrated in the server of the e-commerce platform in the C2M mode, Either integrated in the commodity production management system of the merchant in the C2M mode, or integrated in the user client of the e-commerce platform in the C2M mode. factor, determine the production delay time of the product, and the estimated production total on the day of the production start date, so that when the raw material reserve of the pr...

Embodiment 2

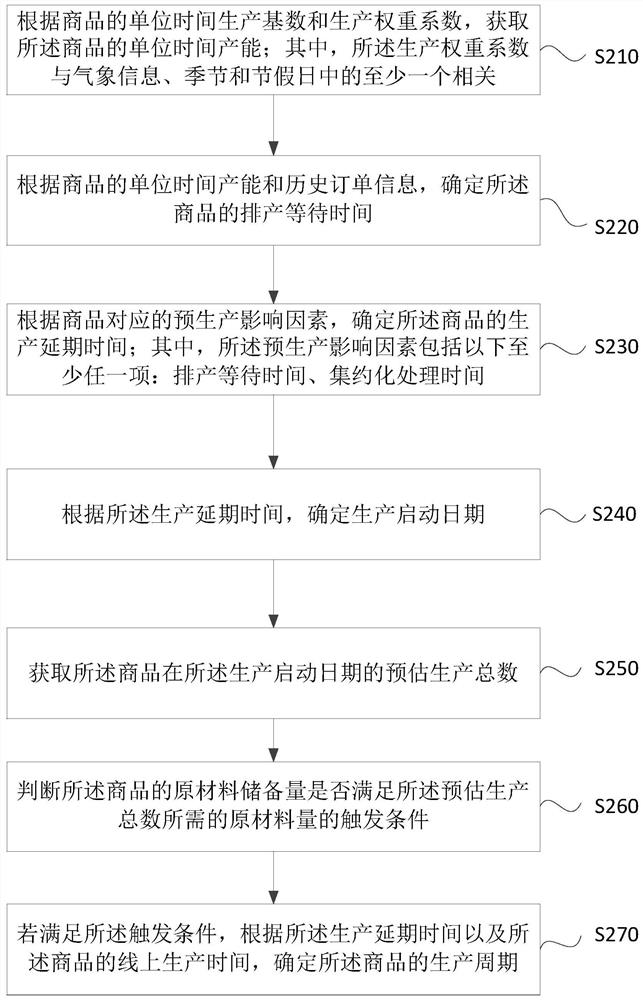

[0065] figure 2 It is a flow chart of a method for determining the production cycle of a commodity provided by Embodiment 2 of the present invention. This embodiment is embodied on the basis of the above-mentioned technical solution. In this embodiment, according to the production base of the commodity per unit time and the production weight coefficient to obtain the production capacity per unit time. Specifically, the method includes:

[0066] S210. Obtain the production capacity per unit time of the commodity according to the production base per unit time and the production weight coefficient of the commodity; wherein the production weight coefficient is related to at least one of weather information, seasons and holidays.

[0067]The production base per unit time of a product can be preset by the merchant based on experience, or the average production capacity per unit time can be obtained as the production base per unit time based on the historical order information of th...

Embodiment 3

[0080] image 3 It is a flow chart of a method for determining the production cycle of commodities provided by Embodiment 3 of the present invention. This embodiment is embodied on the basis of the above technical solution. In this embodiment, according to the current preset intensive time The ordered quantity of the commodity, the preset intensive quantity threshold and the historical order information determine the estimated intensive waiting time of the commodity. Specifically, the method includes:

[0081] S310. According to the preset intensive time and the intensive waiting time of the commodity, obtain the remaining intensive waiting time of the commodity.

[0082] S320. Determine an estimated intensive waiting time of the commodity according to the ordered quantity of the commodity within the current preset intensive time, the preset intensive quantity threshold, and historical order information.

[0083] The number of orders placed for the product within the current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com