Polar plate, fuel cell and assembly method of fuel cell

A fuel cell and assembly method technology, applied in the field of electrochemical cells, can solve the problems of increasing the complexity of electrode plate assembly, large pin hole size, and assembly error of assembly devices, so as to improve the utilization rate of effective area, improve position accuracy, and improve The effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

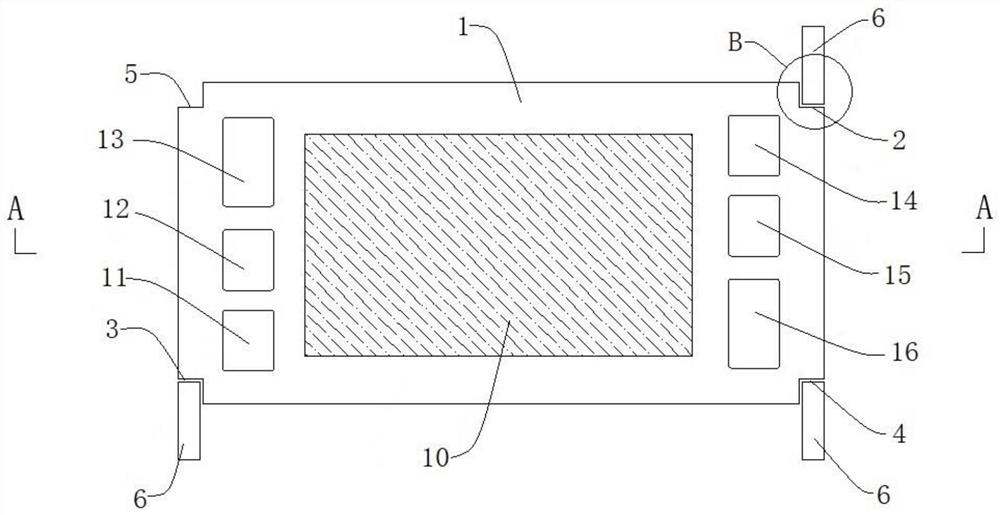

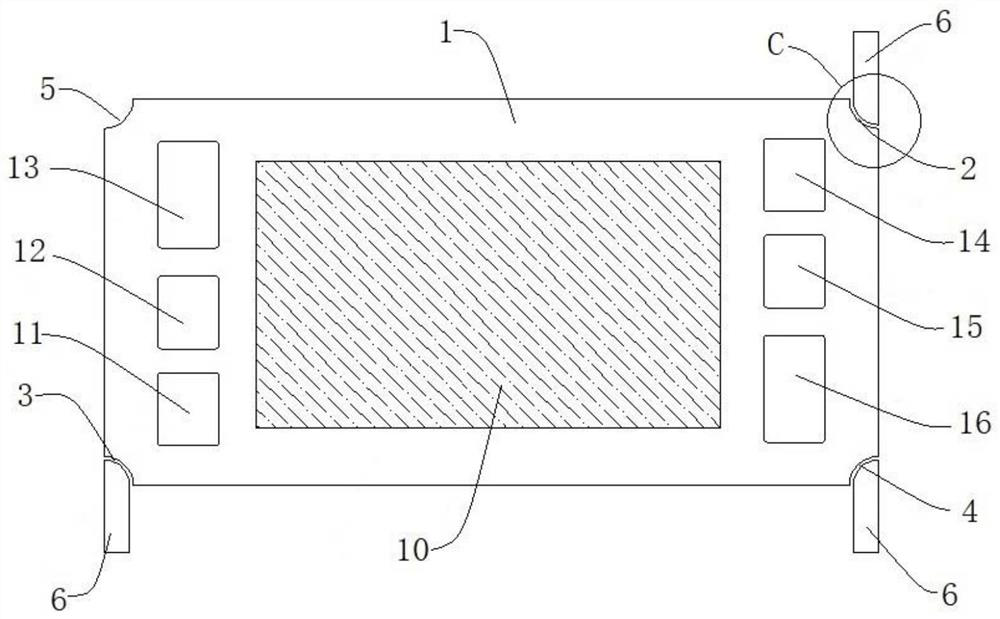

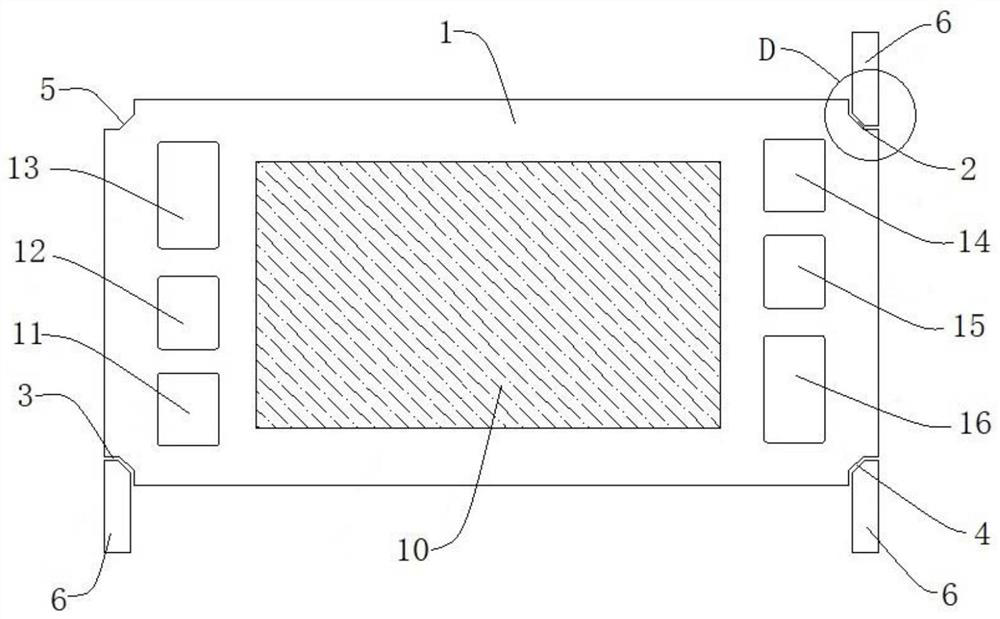

[0031] The following will refer to Figure 1-Figure 8 The pole plate 1 of the present invention will be described in detail in conjunction with the embodiments.

[0032] refer to Figure 1-Figure 5 As shown, the edge of the pole plate 1 according to the embodiment of the present invention is provided with a plurality of open gaps, wherein at least a part of the gaps are positioning gaps, and the positioning gaps are arranged on the edge of the pole plate 1 to help improve the effective area utilization rate of the pole plate 1, At the same time, when the structure or dimension design of the positioning notch is changed, the positioning notch located at the edge of the pole plate 1 has less impact on the function of the pole plate 1 , which is beneficial to save the development and design cycle.

[0033] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com