Ceramic electronic component

A technology of electronic components and ceramics, applied in the field of ceramic electronic components, can solve the problems of low adhesion strength of terminal electrodes and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the ceramic electronic component of the present invention will be described.

[0026] However, the present invention is not limited to the following configurations, and can be appropriately changed and applied within a range that does not change the gist of the present invention. Moreover, the structure which combined two or more of each preferable structure described below is also this invention.

[0027] The ceramic electronic component of the present invention is a ceramic electronic component that can be mounted on a mounting substrate. The present invention can be applied to various laminated ceramic electronic components such as multilayer ceramic substrates, for example. However, the ceramic electronic component of the present invention is not limited to a laminated structure, and may have a single-layer structure.

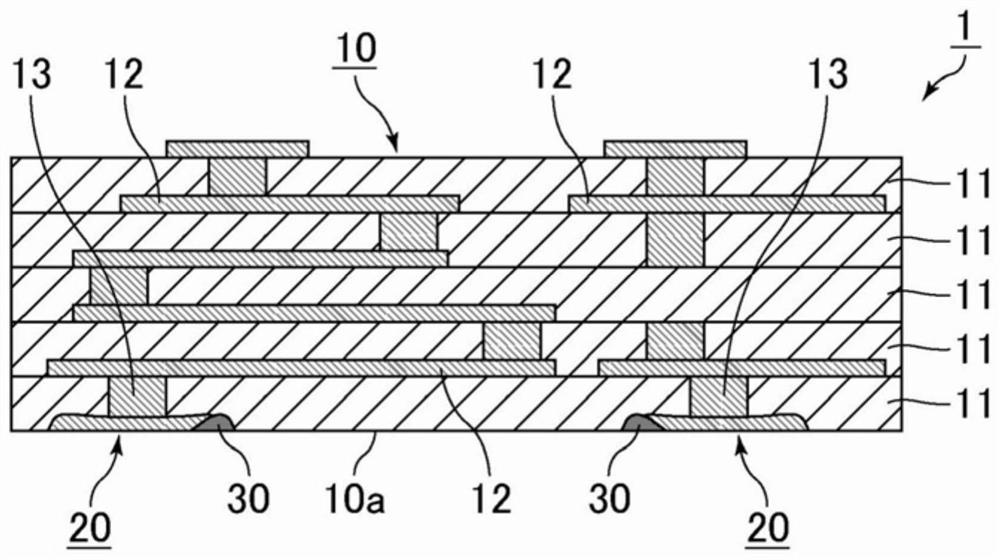

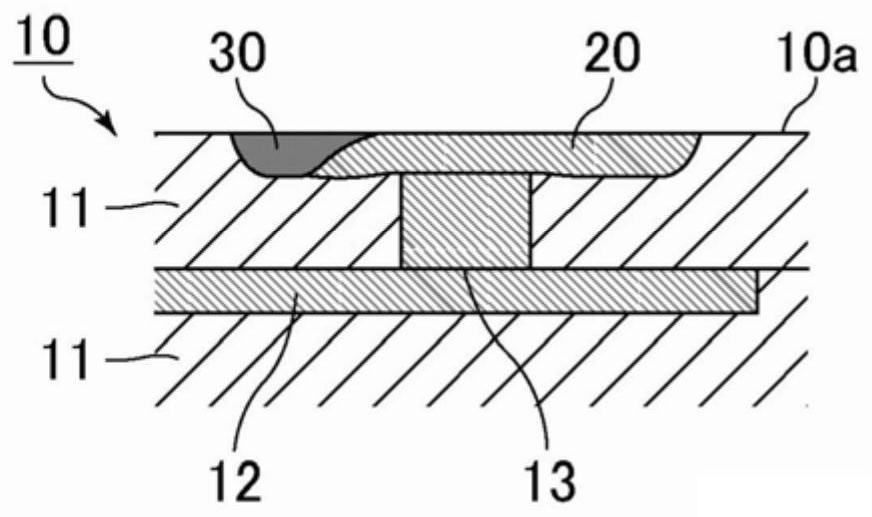

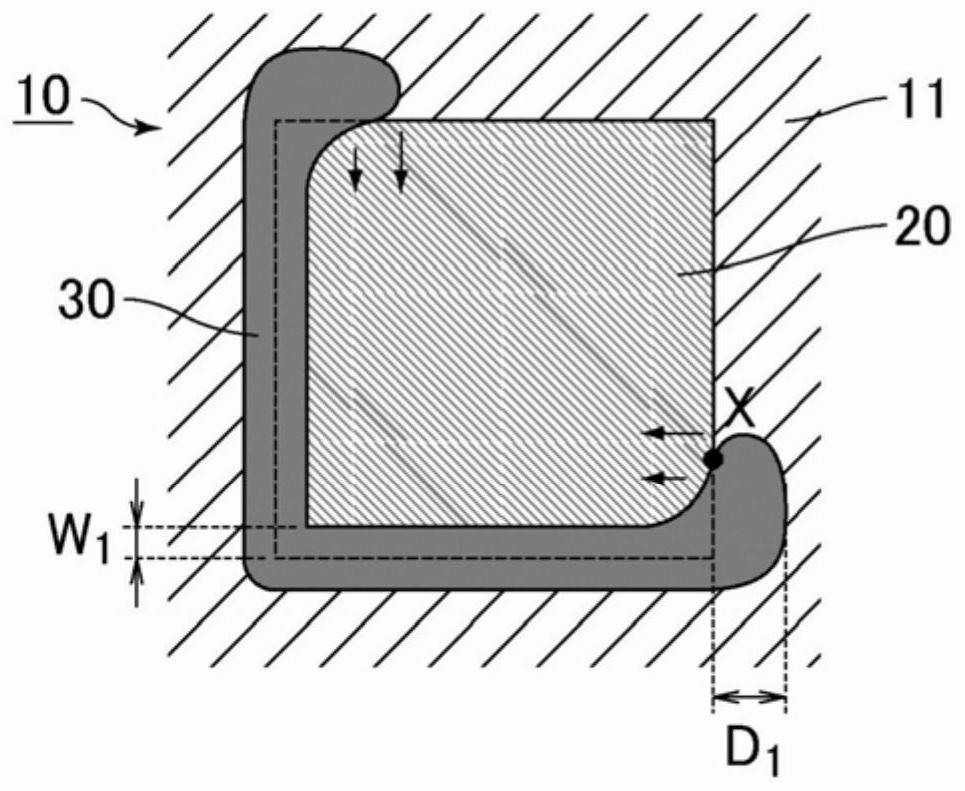

[0028] figure 1 It is a cross-sectional view schematically showing a ceramic electronic component according to one embodiment of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com