Dust removal equipment for astragalus sinicus seed processing and operation method of dust removal equipment

A technology of vetch seeds and dust removal equipment, applied in chemical instruments and methods, separation of solids from solids by air flow, solid separation and other directions, can solve the waste of vetch seeds, low dust removal efficiency and poor dust removal effect. to improve the discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

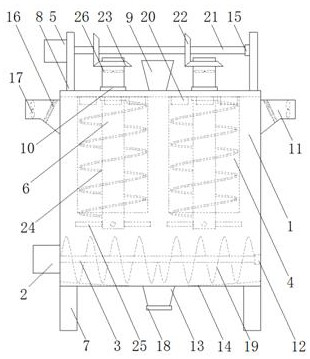

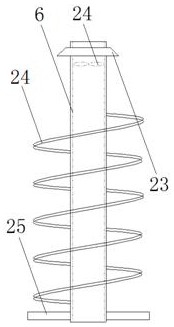

[0029] Append Figure 1-4As shown, a purple dust removal device for seed processing, including a dust removal bucket 1, a motor one 2, a drive shaft, a disc 4, a motor 2 5, and a rotating shaft 6, characterized in that the dust remover is 1 is disposed on the bracket 7, and the plate 8, the feed bin 9, and the bearing one 10 are provided at the top of the dust removal bucket 1, and the bearing 2 12 is provided on the side wall of the bottom portion of the dust removal bucket 1, and the outer side of the dust tub 1 is provided. A drain tube 11 is provided on the wall and a bearing three 15 is provided on the stand 8, and the dust tub 1 and the stent 7, and the plate 8 is connected to the bunter 1 and the bracket 7, the plate 8 is enhanced. The connection strength of the dust removal device is increased, and the motor one 2 is disposed on the outer wall of the bottom of the dust removal bucket 1, the drive shaft one 3 is disposed within the dust release bucket 1, and the transmission...

Embodiment 2

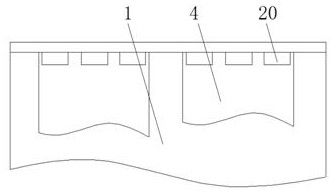

[0044] Append Figure 5-6 As shown, a purple dust removal device for seed processing, including a dust removal bucket 1, a motor one 2, a drive shaft, a disc 4, a motor 2 5, and a rotating shaft 6, characterized in that the dust remover is 1 is disposed on the bracket 7, and the plate 8, the feed bin 9, and the bearing one 10 are provided at the top of the dust removal bucket 1, and the bearing 2 12 is provided on the side wall of the bottom portion of the dust removal bucket 1, and the outer side of the dust tub 1 is provided. A drain tube 11 is provided on the wall and a bearing three 15 is provided on the stand 8, and the dust tub 1 and the stent 7, and the plate 8 is connected to the bunter 1 and the bracket 7, the plate 8 is enhanced. The connection strength of the dust removal device is increased, and the motor one 2 is disposed on the outer wall of the bottom of the dust removal bucket 1, the drive shaft one 3 is disposed within the dust release bucket 1, and the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com