Plastic drainage pipe cutting device capable of achieving rapid center positioning

A center positioning and cutting device technology, which is applied in metal processing and other directions, can solve problems such as difficult clamping and broken pipes, achieve the effects of optimizing the cutting surface, avoiding difficult positioning and clamping, and reducing physical injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top ”, “inner” and “outer” refer to directions toward or away from the geometric center of a particular part, respectively.

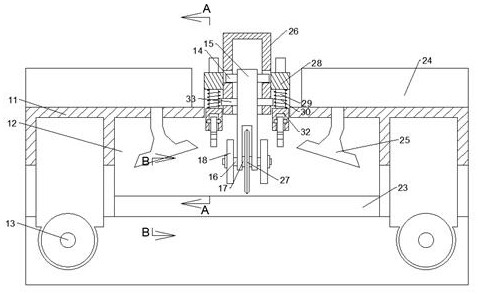

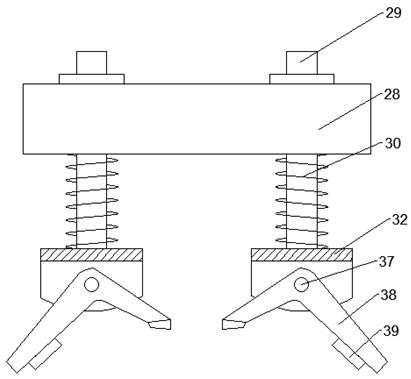

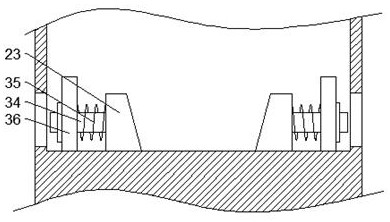

[0019] like Figures 1 to 5 As shown, a fast centrally positioned plastic drainage pipe cutting device includes a cutting machine 11, and a cutting inner cavity 12 is arranged in the cutting machine 11, and a collecting device for automatically absorbing plastic waste is arranged in the cutting inner cavity 12 , the cutting machine 11 is rotatably connected with a transmission wheel 13, and the transmission wheel 13 is provided with a feeding mechanism for the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap