Feeding device for 3D printing

A feeding device and 3D printing technology, applied to 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve problems such as insufficient mixing, single type of raw materials, uneven mixing of multiple raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

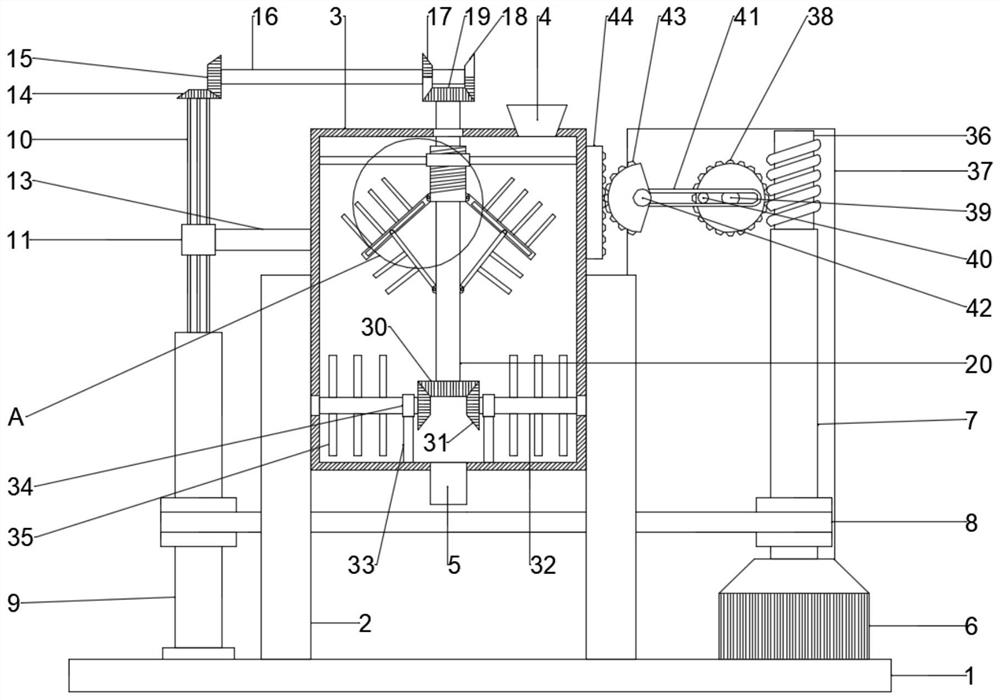

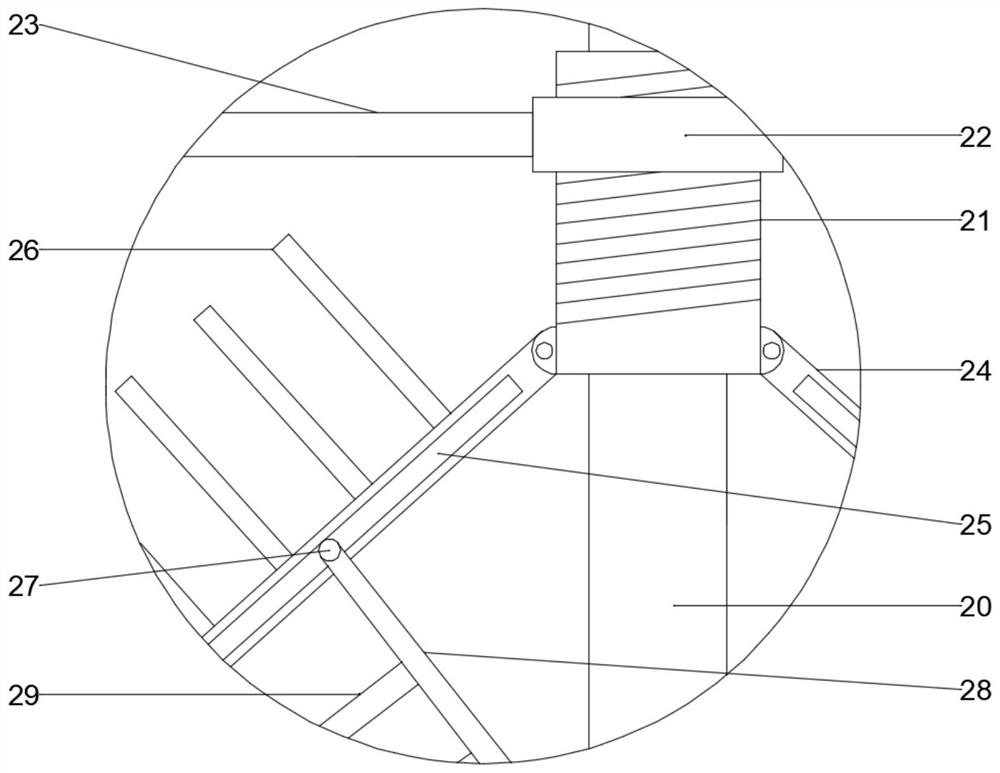

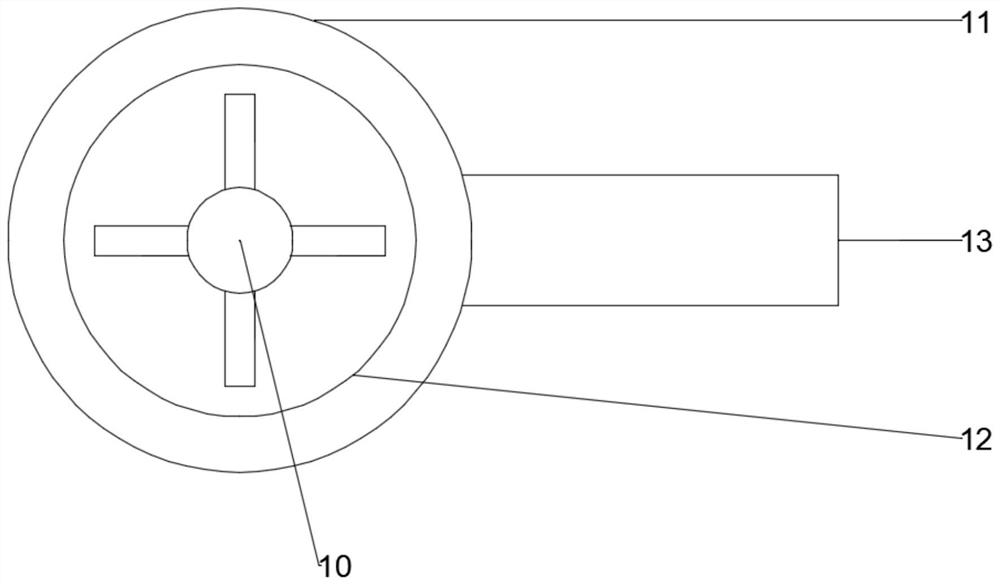

[0023] see Figure 1~4 , in an embodiment of the present invention, a feeding device for 3D printing, including a base 1 and a box body 3, the upper surface of the base 1 is fixedly connected with a support plate 2 symmetrically, and the box body 3 is arranged between the support plates 2 And it is slidably connected with it, the inside of the box body 3 is provided with a first stirring mechanism and a second stirring mechanism, the first stirring mechanism is located above the second stirring mechanism, and a motor 6 is fixedly connected to one side of the upper surface of the base 1, The output end of the motor 6 is fixedly connected with a transmission rod 7, an up and down reciprocating mechanism is arranged above the transmission rod 7, and a drive mechanism is provided on the side of the box body 3 away from the motor 6, and the drive mechanism is a first stirring mechanism Provide power with the second stirring mechanism, the top side of the box body 3 is fixedly conne...

Embodiment 2

[0029] see Figure 5 , on the basis of Embodiment 1, a chute 45 is provided inside the support plate 2, and a slider 46 is slidably connected to the inside of the chute 45, and the slider 46 is fixedly connected to the outer wall of the box body 3, and the slider 46 is fixedly connected to the outer wall of the box body 3. A spring 47 is fixedly connected to the lower surface of the block 46 , and the lower end of the spring 47 is fixedly connected to the lower surface of the chute 45 .

[0030] The working principle of the present invention is: pour the printing material into the box body 3, start the motor 6, the motor 6 drives the transmission rod 7 to rotate, and the belt transmission mechanism 8 drives the card slot column 9 to rotate, and the card slot column 9 drives the card column 10 to rotate , the card column 10 drives the first bevel gear 14 to rotate, the first bevel gear 14 drives the second bevel gear 15 to rotate, the second bevel gear 15 drives the connecting ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap