A system and process of hydrogen -based hydrogen -based hydrogen -based hydrogen -based hydrogen -based hydrogen -based hydrogen -based hydrogen -based hydrogenation of amino thermal chemical energy storage

A high-temperature electrolysis and thermochemical technology, applied in the chemical industry, electrolysis components, electrolysis process, etc., can solve the problems of harsh reaction conditions, incomplete conversion, and high operating costs of energy storage systems, achieving strong fluidity and low compressibility. , the effect of high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

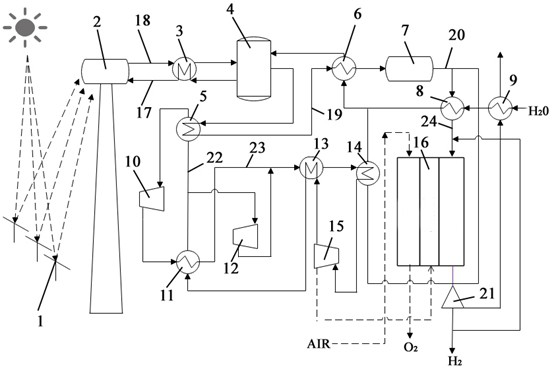

[0026] The direct solar radiation intensity is taken as 1kW / m 2 , the concentration ratio is 200, which aims to test the feasibility of the system under normal illumination and concentration conditions; the solar heat collector provides the heat required for the ammonia decomposition reaction in the endothermic reactor 2 and maintains the temperature of the reaction. To ensure the progress of the reaction, the length of the endothermic reactor 2 is 355mm and the diameter is 30mm; the liquid ammonia exchanges heat from the normal temperature pressure storage tank 4 to the first heat exchanger 3, and the temperature rises from the normal temperature to about 400 ℃ and then enters the endothermic Reactor 2, the ammonia decomposition reaction occurs in the endothermic reactor 2 to make the product N 2 , H 2 The temperature rises to about 700°C, then enters the first heat exchanger 3 for heat exchange, and finally is stored in the normal temperature and pressure storage tank 4; 2...

Embodiment 2

[0028] The liquid ammonia exchanges heat from the normal temperature pressure storage tank 4 to the first heat exchanger 3, and the temperature rises from the normal temperature to about 400 ° C and then enters the endothermic reactor 2, where the ammonia decomposition reaction occurs in the endothermic reactor 2 to make the product N 2 , H 2 The temperature rises to about 700°C, enters the first heat exchanger 3 for heat exchange, and is finally stored in the normal temperature and pressure storage tank 4; 2 , H 2 First enter the fifth heat exchanger 5 for heat exchange to raise the temperature from normal temperature to about 250°C, the total flow of the reaction gas is 4.25g / s, and then enter the second heat exchanger 6 for heat exchange to raise the temperature from 250°C to 630°C , and finally enter the adiabatic reactor 7 to produce ammonia synthesis reaction, the length of the adiabatic reactor is 115cm, and the length of the adiabatic reactor is 18mm directly. The li...

Embodiment 3

[0030] The liquid ammonia exchanges heat from the normal temperature pressure storage tank 4 to the first heat exchanger 3, and the temperature rises from the normal temperature to about 400 ° C and then enters the endothermic reactor 2, where the ammonia decomposition reaction occurs in the endothermic reactor 2 to make the product N 2 , H 2 The temperature rises to about 700°C, enters the first heat exchanger 3 for heat exchange, and is finally stored in the normal temperature and pressure storage tank 4; 2 , H 2 First enter the fifth heat exchanger 5 for heat exchange to raise the temperature from normal temperature to about 250°C, the total flow rate of the reaction gas is 4.36g / s, and then enter the second heat exchanger 6 for heat exchange to raise the temperature from 200°C to 620°C , and finally enter the adiabatic reactor 7 to generate ammonia synthesis reaction, the length of the adiabatic reactor is 120cm, and the length of the adiabatic reactor is 20mm directly. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com