Wool fabric as well as processing system and processing method thereof

A processing system and fabric technology, applied in the field of wool fabric and its processing system, can solve the problems of not being able to improve the performance of wool fabric, reduce the overall processing time of wool fabric, etc., and achieve the effect of reducing burrs and facilitating absorption and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

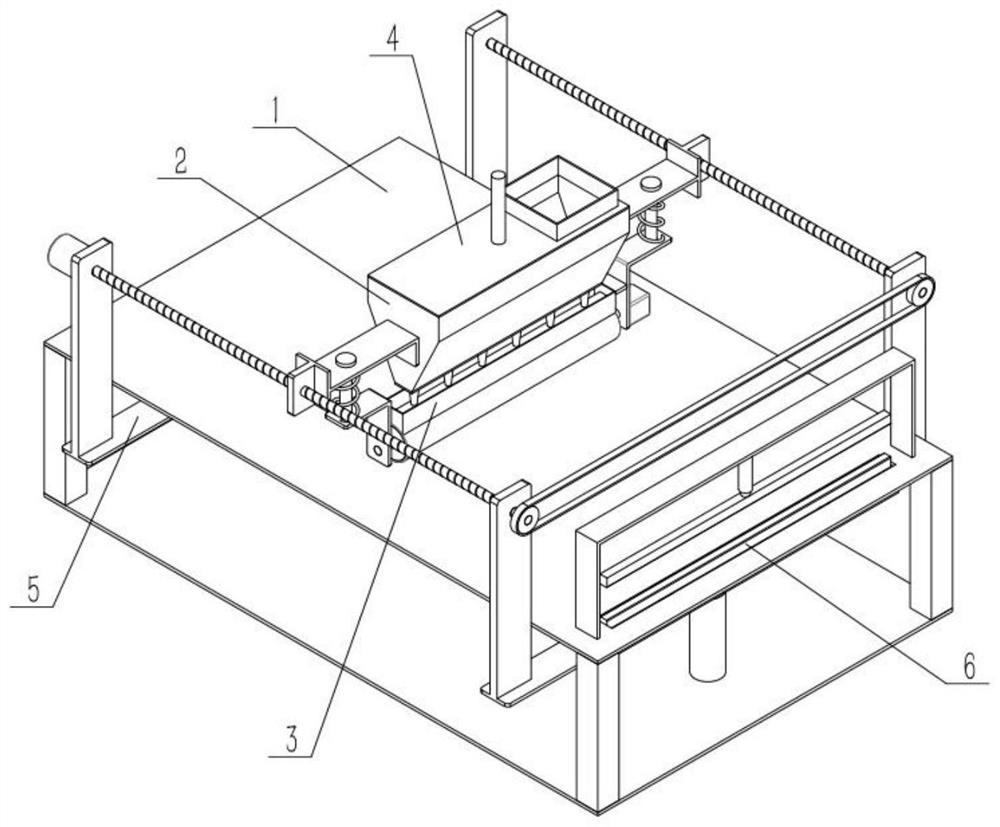

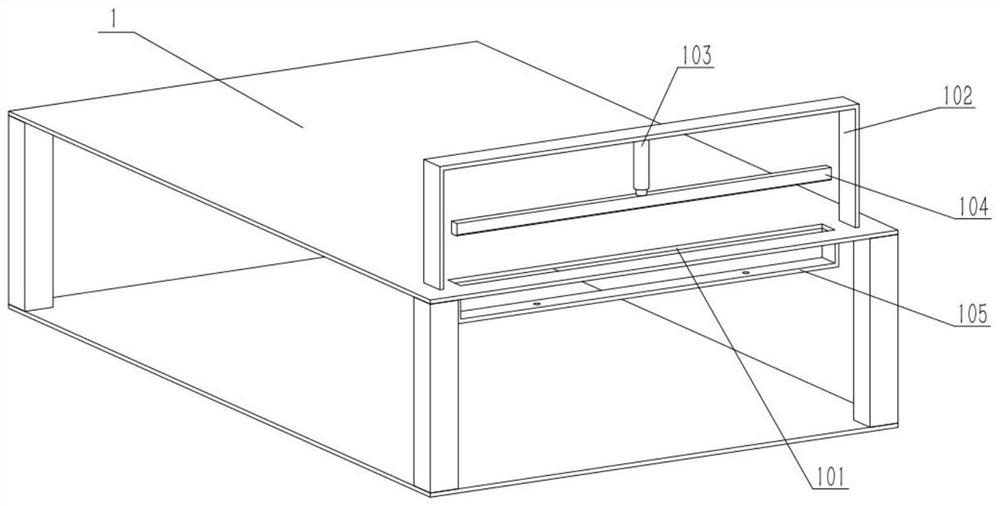

[0033] As shown in the figure, a wool fabric processing system includes a flat laying platform 1, a long notch 101, a bridge frame I102, an electric push rod I103, a pressing bar I104, a bridge frame II105 and a pressing bar II6. There is a long notch 101 on the right side of the bridge, the bridge I102 is fixed on the flat platform 1, the bridge I102 is set directly above the long notch 101, the electric push rod I103 is fixed on the lower end of the bridge I102, and the movable end of the bridge I102 The pressing bar I104 is fixed, the pressing bar I104 is set directly above the long slot 101, the bridge II105 is fixed at the lower end of the tiling platform 1, the bridge II105 is set directly below the long slot 101, and the upper end of the bridge II105 is set There is a pressing strip II6, the upper end surface of the pressing strip II6 is higher than or equal to the upper end surface of the tiling platform 1 . Pressing bar Ⅱ6 is located directly below pressing bar Ⅰ104. ...

specific Embodiment approach 2

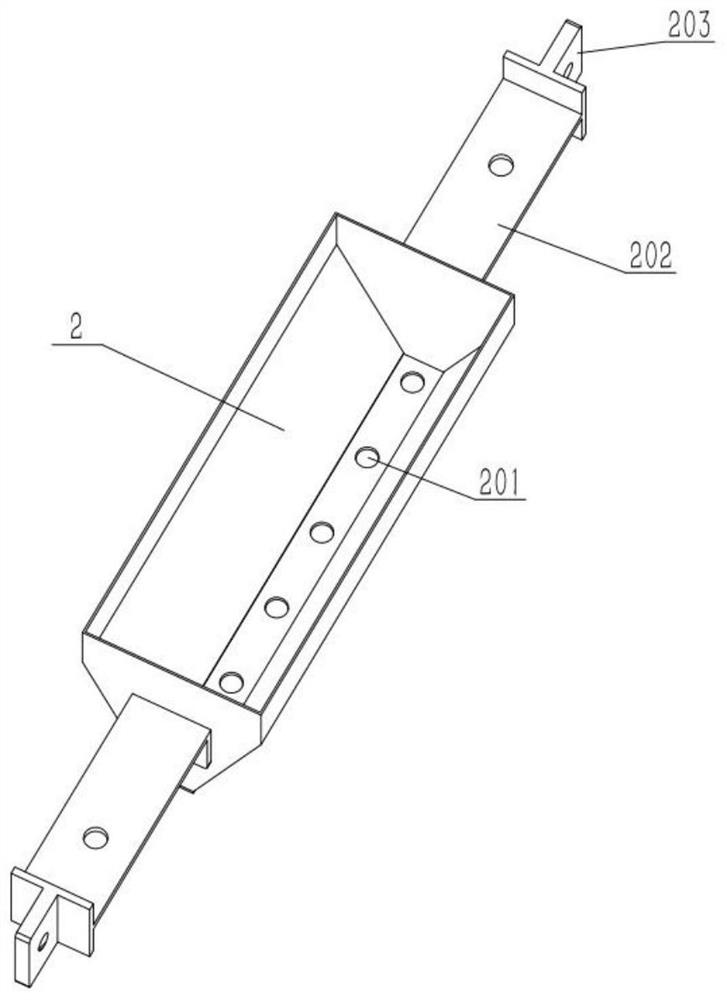

[0035] As shown in the figure, the wool fabric processing system also includes a limit column II601, the lower end of the pressing bar II6 is fixedly connected with two limit columns II601, the limit column II601 is slidably connected to the bridge frame II105, and the limit column II601 is There is a compression spring I, and the two ends of the compression spring I are respectively in contact with the bridge frame II105 and the pressing bar II6. When the upper surface of the pressing bar II6 is higher than the flat-laying platform 1, the woolen fabric is placed on the upper end surface of the pressing bar II6, and then the pressing bar II6 is lowered to hold down the woolen fabric, and the pressing bar II6 is pressed down, Until the upper end surface of the pressing strip II6 coincides with the upper end surface of the tiling platform 1, at this time, the elastic force is used to press and hold the wool fabric, and because the pressing strip II6 has upward elasticity, the low...

specific Embodiment approach 3

[0037] As shown in the figure, the left and right width of the pressing bar II6 is smaller than the left and right width of the long notch 101 . In the process of smoothing the woolen fabric, the floating wool falls through the long notch 101 to reduce the floating wool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com