Methods for preparing shredded mushroom and mushroom dried meat floss

A technology of shredded shiitake mushrooms and shiitake mushrooms, which is applied in food preparation, application, food science, etc. It can solve the problems that product quality is difficult to be guaranteed, no sterilization process is adopted, and cannot be completely removed, so as to achieve complete sterilization and avoid bad discoloration , the effect of suitable taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

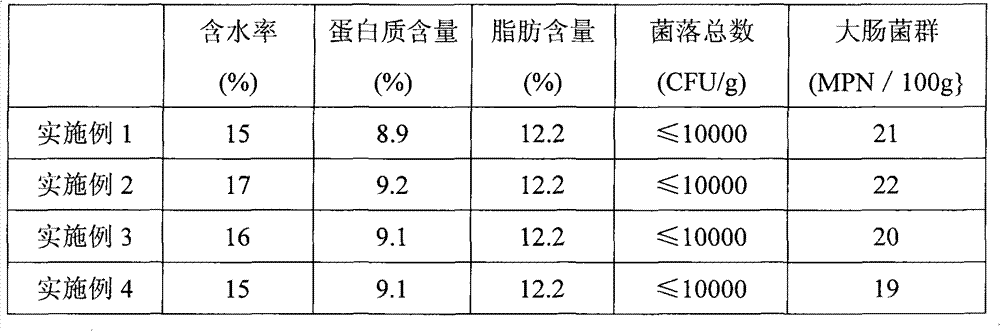

Examples

Embodiment 1

[0046] Embodiment 1 prepares mushroom beef floss

[0047] 1. Soaking treatment

[0048] Select shiitake mushroom stalks with light color, no mildew, no insects, no sawdust and other impurities as raw materials, put the dried shiitake mushroom stalks into a cleaning container, soak in water, make the shiitake mushroom stalks completely submerged in water, absorb water evenly, and stir continuously during soaking And remove impurities on the stalk until the water content of the soaked mushroom stalk reaches 75%, wherein the ratio of the weight (dry weight) of the mushroom stalk to the weight of water is 1:2.

[0049] If fresh shiitake mushroom stalks are used as raw materials, it does not need to be soaked and can be washed directly.

[0050] 2. Softening treatment

[0051] Rinse the soaked shiitake stalks with water for 3 times, further remove impurities, add water, heat and boil for 20 minutes, and keep stirring, soften the shiitake stalks to obtain softened shiitake stalks,...

Embodiment 2

[0076] Embodiment 2 prepares mushroom pork floss

[0077] The soaking treatment step is except that the weight (dry weight) of the shiitake mushroom stalk and the weight ratio of water is 1: 1.5, and the water content of the shiitake mushroom stalk after soaking is 72%, all the other are the same as in Example 1;

[0078] The softening treatment step is 25min except that the boiling time is 25min, and the weight (dry weight) of the mushroom stalk and the weight ratio of water are 1: 1, all the other are identical with embodiment 1;

[0079] The acidification treatment step is 35min except soaking time, and the weight ratio of mushroom handle (dry weight) and wood vinegar is 1: 1.5, and the mass percent concentration of organic acid in wood vinegar is 3%, all the other are identical with embodiment 1 ;

[0080] The saturated steam treatment step is the same as in Example 1 except that the relative pressure of the high-pressure saturated water vapor is 0.137MPa, the temperature...

Embodiment 3

[0086] Embodiment 3 prepares mushroom chicken floss

[0087] The soaking treatment step is the same as Example 1 except that the water content of the shiitake stalk after soaking is 70%;

[0088] The softening treatment step is except that boiling time is 30min, and the weight (dry weight) of mushroom stalk and the weight ratio of water are 1: 1.5, all the other are identical with embodiment 1;

[0089] The acidification treatment step is except that soaking time is 35min, and the mass percent concentration of organic acid in the wood vinegar is 3%, and the ratio of the weight of mushroom handle (dry weight) and wood vinegar is 1.9: 1, all the other are identical with embodiment 1 ;

[0090] Saturated steam treatment step is except that treatment time is 7min, all the other are identical with embodiment 1;

[0091] The beating processing step is except that beating time is 6min, and the diameter of the shiitake shiitake shiitake silk that makes is 0.5mm, all the other are id...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com