A kind of prebaked frozen dough and its preparation method

A technology of freezing dough and pre-baking, which is applied in the direction of pre-baking dough processing, baking, dough preparation, etc. It can solve the problems of affecting dough fermentation, long proofing time, and affecting the quality of final products, and achieves a simple and easy fixing process The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

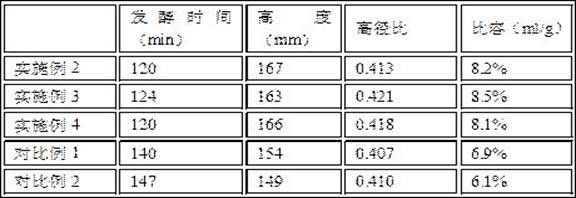

Examples

Embodiment 1

[0030] First, making the immobilized enzyme system in the improver of the present invention specifically includes the following steps:

[0031] S1. Using ionic liquid 1-butyl-3-methylimidazolium chloride as a solvent to dissolve cellulose and silk fibroin, and using water as a coagulation bath to obtain a silk fibroin-cellulose mixture;

[0032] S2. Filter the above-mentioned silk fibroin-cellulose mixture with a 0.5 micron filter membrane, dry it, and then grind it into powder, and the particle size of the powder is 50-80nm;

[0033] S3. Add a certain amount of phosphate solution with a mass concentration of 0.5-2.6% to the above powdered silk fibroin-cellulose, and stir evenly to form a carrier phosphate solution; the mixing mass ratio of the above substances is 1:10;

[0034] S4. Spray and dry the above-mentioned carrier phosphate solution with a concentration of 0.5-2.6%, and add α-amylase, β-amylase and isoamylase powder enzyme system in the form of spray; α-amylase, β-am...

Embodiment 2

[0039] The composition of the dough made in this embodiment includes, by weight: 50% wheat flour, 9.0% sugar, 0.2% salt, 2.2% milk powder, 1.2% improver, 0.3% yeast, 11.0% butter , 5.2% eggs, 24.0% water.

[0040] Among them, the improvement agent preparation includes 9.0% immobilized enzyme system, 1.8% pentosanase, 0.3% lipase, 0.9% glucose oxidase, 8.5% zein, 3% vitamin C, sodium stearoyl lactylate 2 %, 3% sucrose fatty acid ester monoglyceride, 3% sucrose fatty acid ester diglyceride, 6% sodium alginate, 4% gum arabic and 25% gluten and the rest of the starch additive; the prepared improved The above-mentioned certain dosage is added to the raw materials for making dough.

[0041] Use above-mentioned raw material to carry out the making of dough and comprise the steps:

[0042] S1. Stir each component of the above-mentioned improver and yeast evenly, and stir with a small amount of warm water until it becomes a paste for use;

[0043] S2. Take the above dosage of wheat ...

Embodiment 3

[0047] The composition of the dough made in the present embodiment comprises, by weight percentage: 53% wheat flour, 8.6% sugar, 0.6% salt, 1.7% milk powder, 2.0% improver, 0.5% yeast, 8.5% butter , 6.2% eggs, 21.0% water.

[0048] Among them, the improver is 12.0% by weight of fixed enzyme system, 0.7% of pentosanase, 0.2% of lipase, 0.3% of glucose oxidase, 8.5% of zein, 0.7% of vitamin C, sucrose fat 5% monoglyceride of sucrose fatty acid ester, 5% diglyceride of sucrose fatty acid ester, 5% triglyceride of sucrose fatty acid ester, 1% carrageenan, 1% gum arabic and 45% gluten and the rest starch additive The prepared improver gets the above dosage and adds it to the raw materials for making the dough.

[0049] The dough production steps using the above raw materials also include spraying ice water (2-3°C) on the surface of the dough before placing it in a freezing environment. Other production steps are the same as in Example 2. A layer of ice crystals is formed, which p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com