Temperature measurement method of divertor target plate of tokamak device based on single-wave filtering

A tokamak and temperature measurement technology, applied in temperature recording, optical radiation measurement, radiation pyrometry, etc., can solve the problems of inability to quickly respond to target temperature changes, no tokamak device, etc., and achieve fitting results Accurate and improve the effect of temperature measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

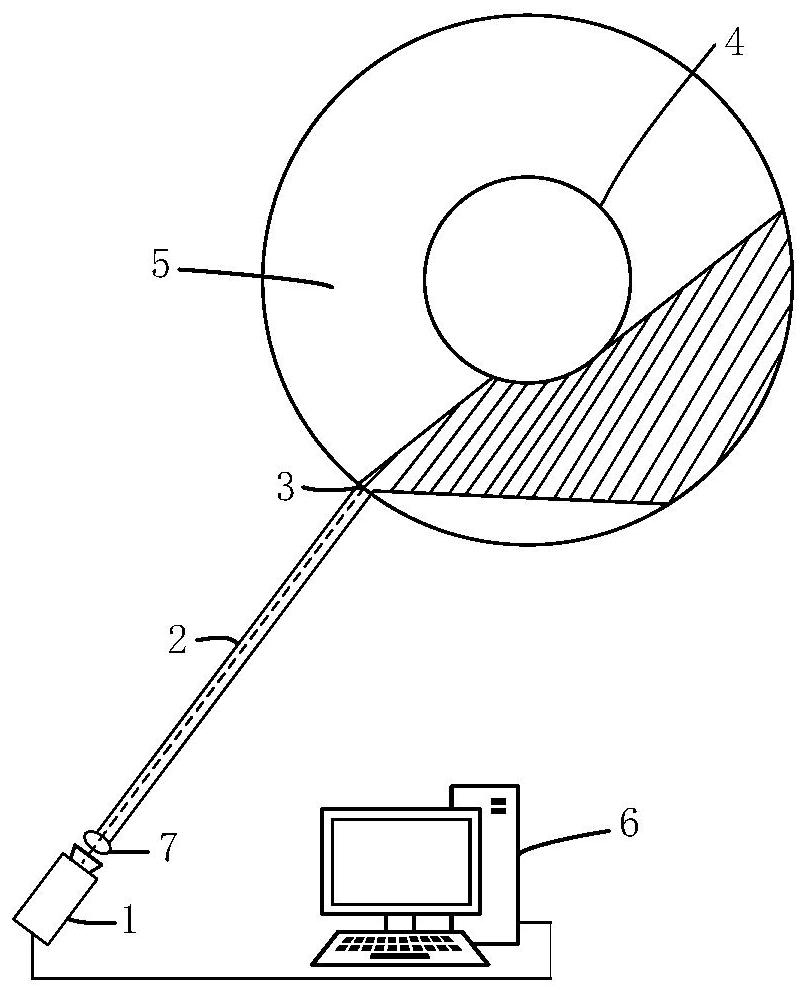

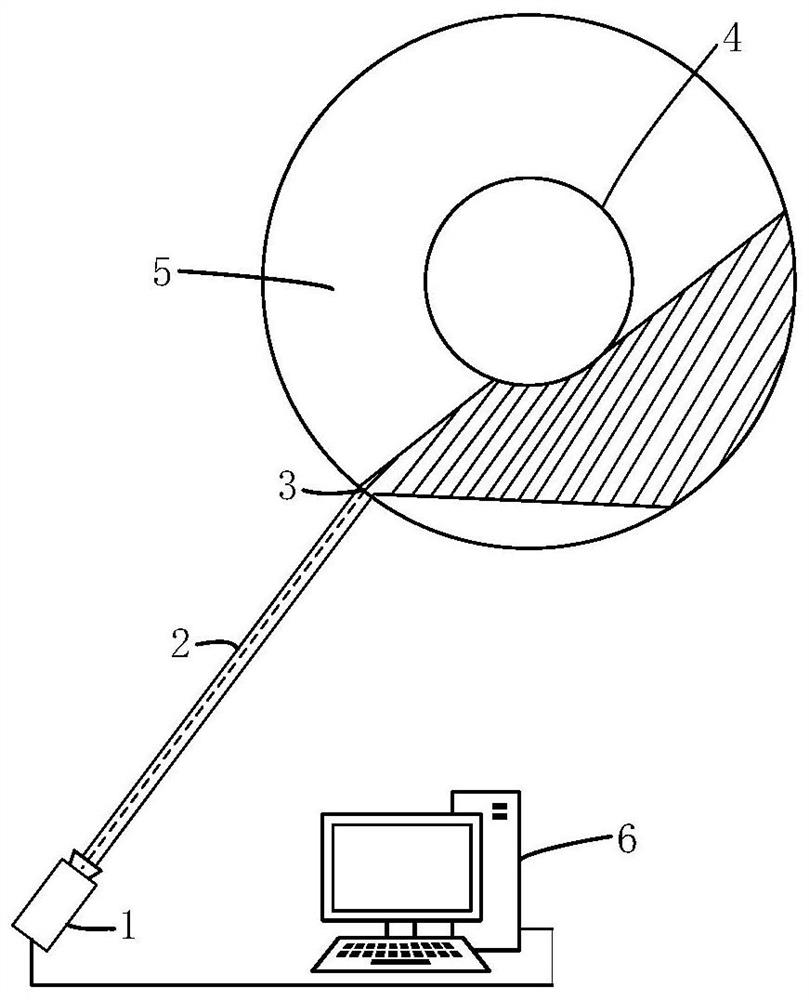

[0108] (1) First follow figure 1 As shown, an infrared narrow-band filter with a center wavelength of 10200nm and a bandwidth of 100nm is installed in front of the infrared thermal imager lens. One end of the special light path is connected to the window of the tokamak device, and the other end is connected to the infrared filter, so that the radiation inside the tokamak device can enter the special light path from the window, and the radiation that can pass through the filter will be measured by the thermal imager to and displayed on the control software interface in the form of a grayscale image.

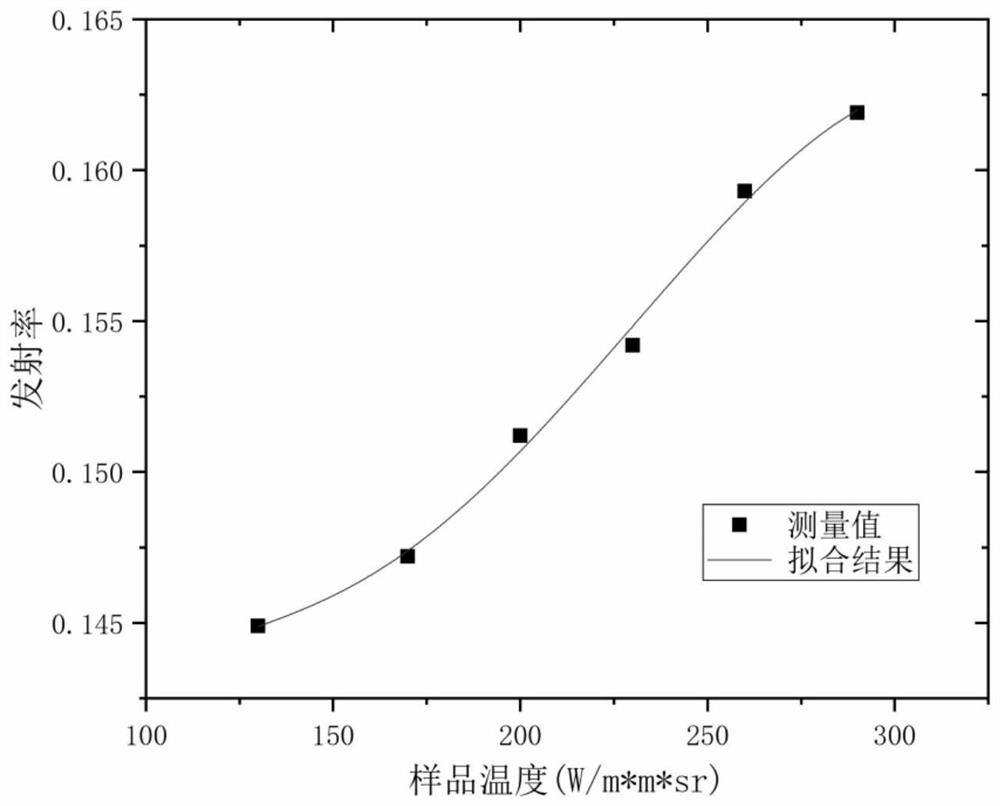

[0109] (2) The infrared thermal imager is connected to the industrial computer through a gigabit network cable. The industrial computer controls all operations of the infrared thermal imager. Set the emissivity to 1 in the thermal imager control software on the industrial computer, and read the collected The gray value of a point in the image can calculate the radiation value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com