A silicon carbide linear temperature sensor, temperature measurement method and manufacturing method thereof

A technology of temperature sensor and silicon carbide, which is applied in thermometers, thermometers with directly heat-sensitive electric/magnetic elements, instruments, etc., can solve the problems of integrated crosstalk and low sensitivity of main devices, and achieve the goal of reducing crosstalk, improving sensitivity, The effect of a large temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

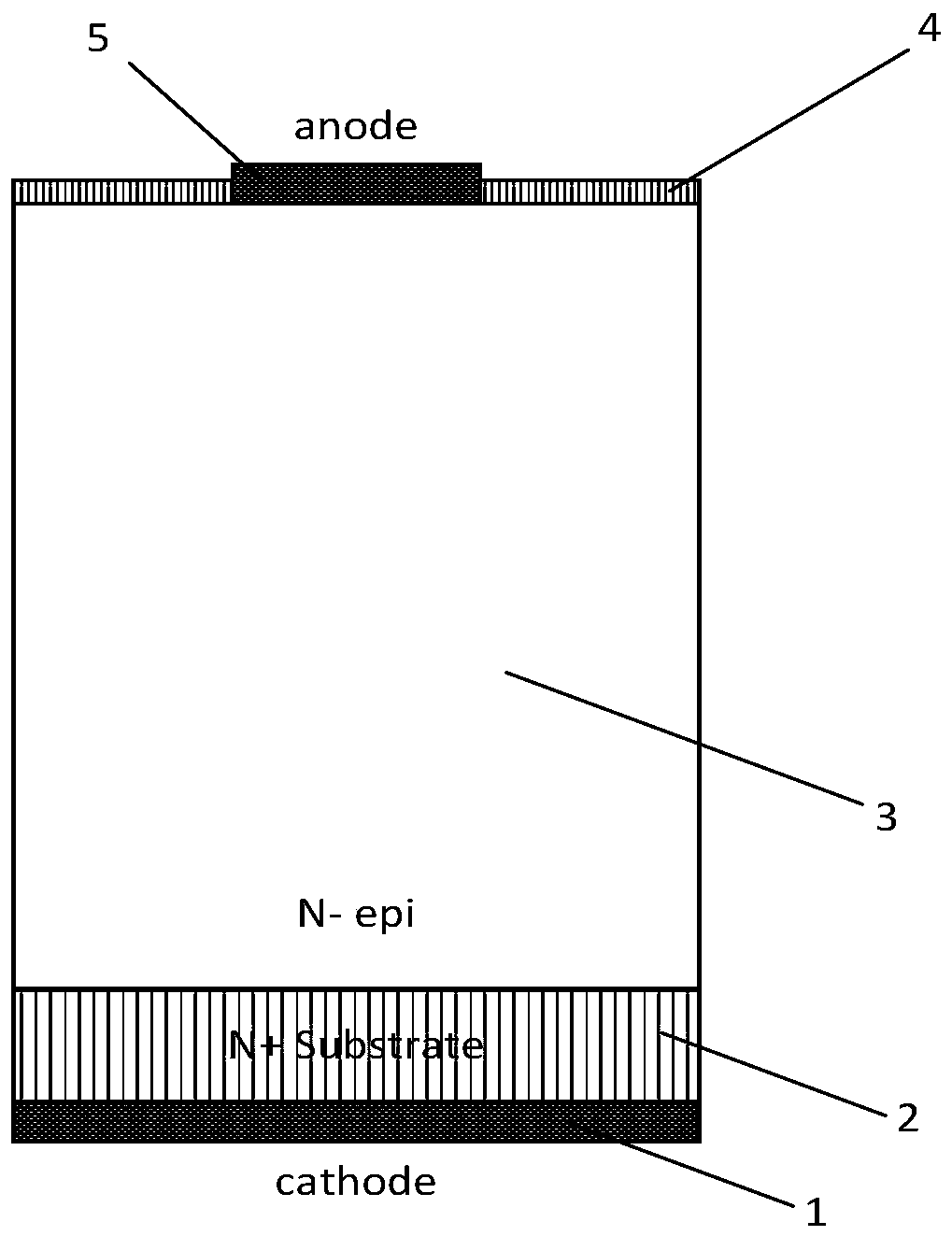

[0061] Such as figure 1 Shown is a SiC SBD temperature sensor with a traditional vertical structure. In order to compare its performance with the temperature sensor of the present invention, this embodiment adopts the same doping level to make a vertical SiC SBD temperature sensor, as follows: silicon carbide N- epitaxial layer The doping concentration of 2 is 2E17cm -3 Yes, the thickness of the silicon carbide N- epitaxial layer 2 is 10 microns, the metal Ti / Al alloy is used as the Schottky contact electrode 8, and the metal Ni is used as the ohmic contact electrode 7.

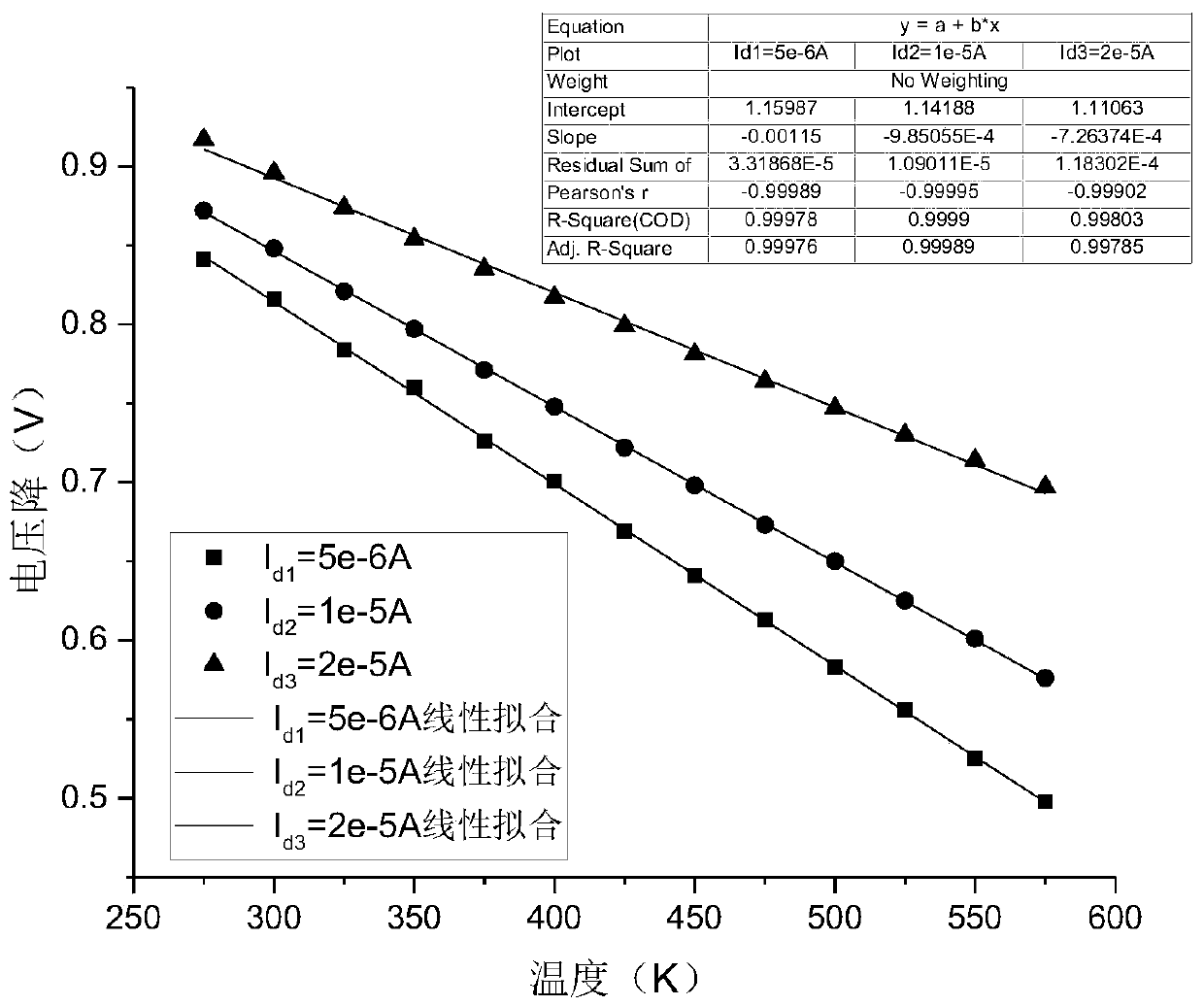

[0062] This embodiment adopts TCAD software Silvaco to build such as figure 1 device structure, in order to obtain its V-T characteristic curve, its Schottky contact electrode 8 is respectively biased with a constant current of 5E-6A, 1E-5A and 2E-5A, when the current through the SBD is constant, its Xiao The forward voltage drop on the TG barrier will change linearly with the temperature. Using this princi...

Embodiment 2

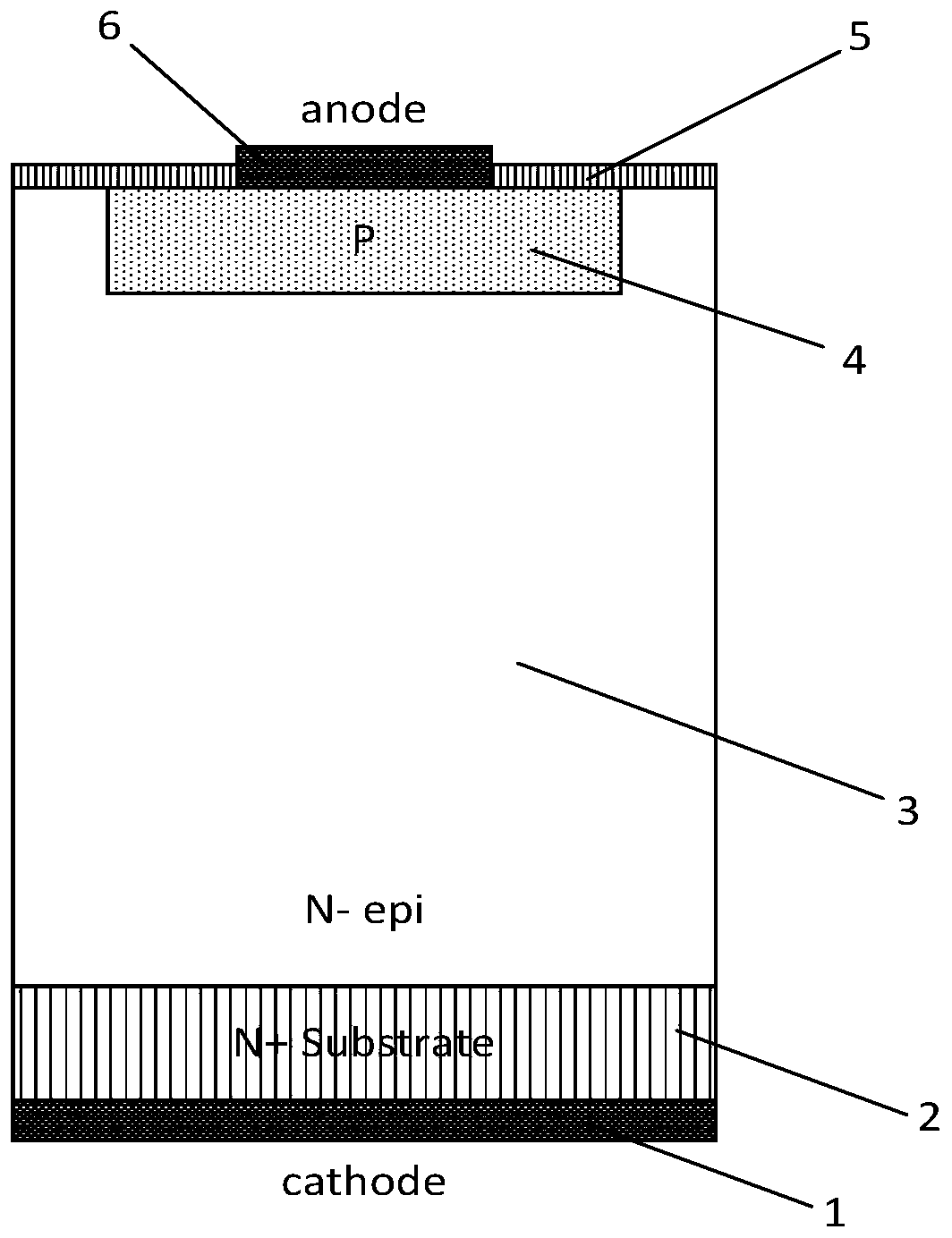

[0064] Such as image 3 Shown is a SiC PN junction temperature sensor with a traditional vertical structure. In order to compare its performance with the temperature sensor of the present invention, this embodiment adopts the same doping level to make a vertical SiC PN temperature sensor, as follows: silicon carbide N-epitaxy The doping concentration of layer 2 is 2E17cm -3 The thickness of the silicon carbide N-epitaxial layer 2 is 10 microns, the metal Al is used as the Schottky contact electrode 8, the metal Ni is used as the ohmic contact electrode 7, and the doping concentration of the P well region 3 is 2E17cm -3 , the thickness of the P well region 3 is 2 microns.

[0065] This embodiment adopts TCAD software Silvaco to build such as image 3 In order to obtain its V-T characteristic curve, its ohmic contact electrode 7 is respectively biased with a constant current of 5E-5A, 1E-4A and 2E-4A. When the current passing through the PN junction is constant, its PN junctio...

Embodiment 3

[0067] Such as Figure 5 Shown is a specific embodiment of the SiC temperature sensor with a lateral double SBD structure provided by the present invention, which is characterized in that it includes a silicon carbide N+ substrate 1, and a silicon carbide N+ substrate 1 is provided above the silicon carbide N+ substrate 1. - epitaxial layer 2, the SiC N - The center of the top layer of the epitaxial layer 2 has a P well region 3, the center of the top layer of the P well region 3 has an N well region 4, and the middle position of the top layer of the N well region 4 has an N-type silicon carbide ohmic contact region 5, and the N-type silicon carbide ohmic contact region An ohmic contact electrode 7 connected to it is arranged on the top of the region 5, and two Schottky contact electrodes 8 connected thereto and arranged symmetrically above the two ends of the top layer of the N well region 4, the two Schottky contact electrodes 8 and The ohmic contact electrodes 7 are indepe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com