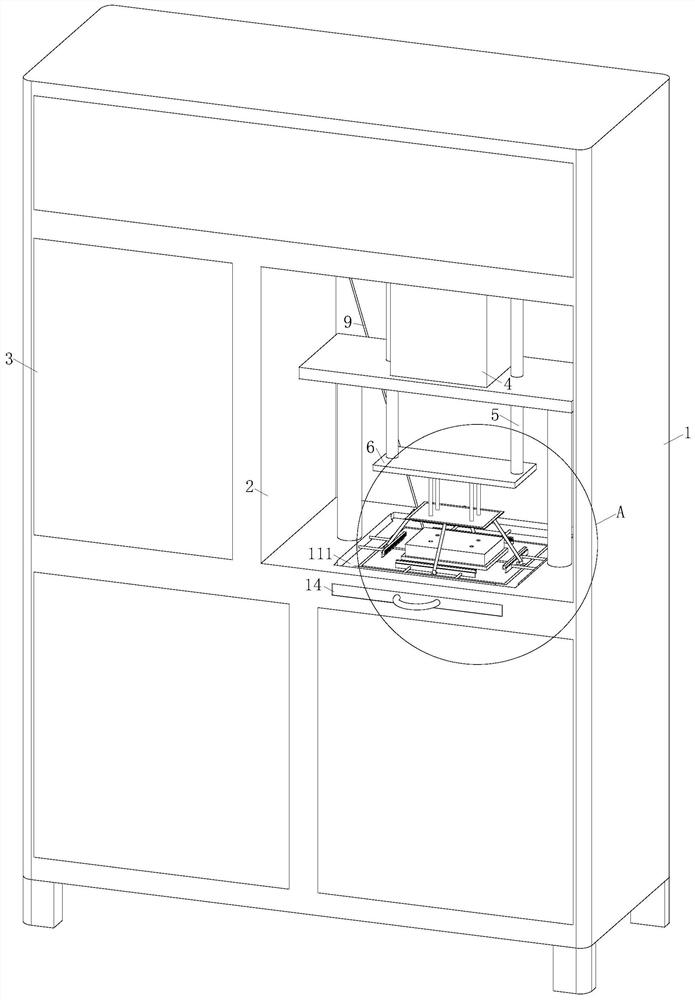

Air tightness high-precision testboard for motor cover

A test bench, air tightness technology, applied in liquid tightness measurement using liquid/vacuum degree, by measuring the rate of increase and deceleration of fluid, by detecting the appearance of fluid at the leak point, etc., it can solve the problem of not being able to determine the leakage of the test piece location, inability to test parts to be repaired and reused, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

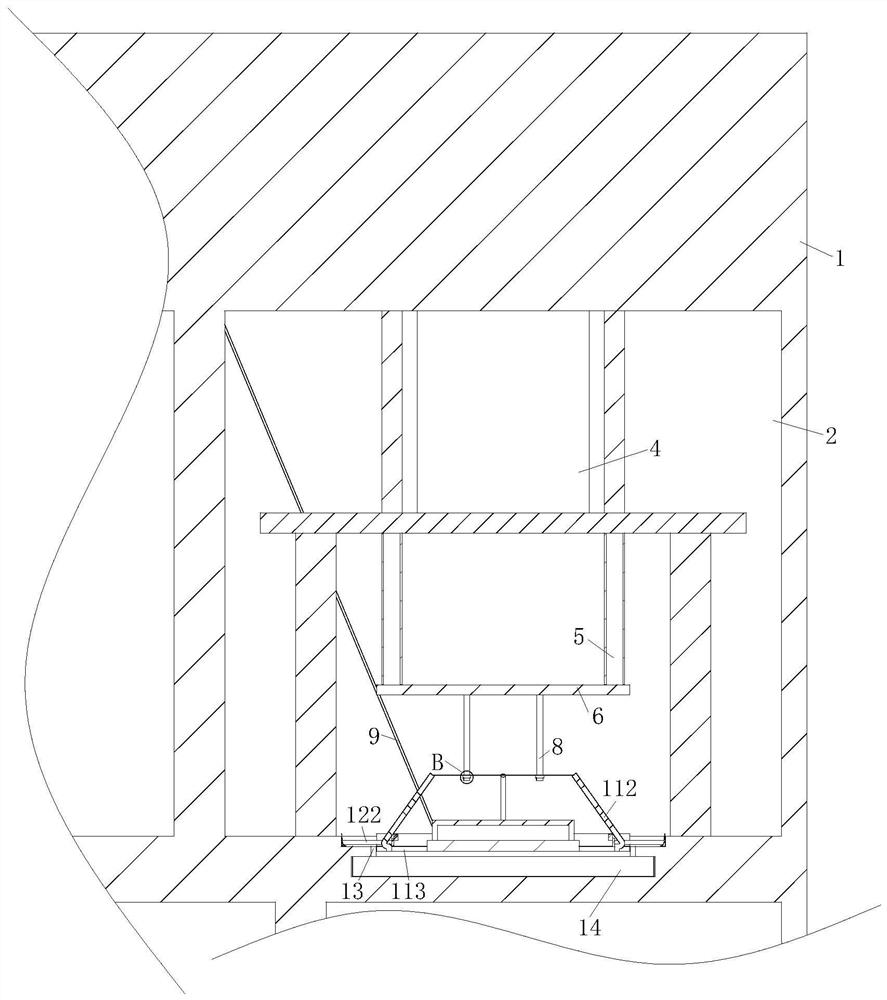

Method used

Image

Examples

Embodiment approach

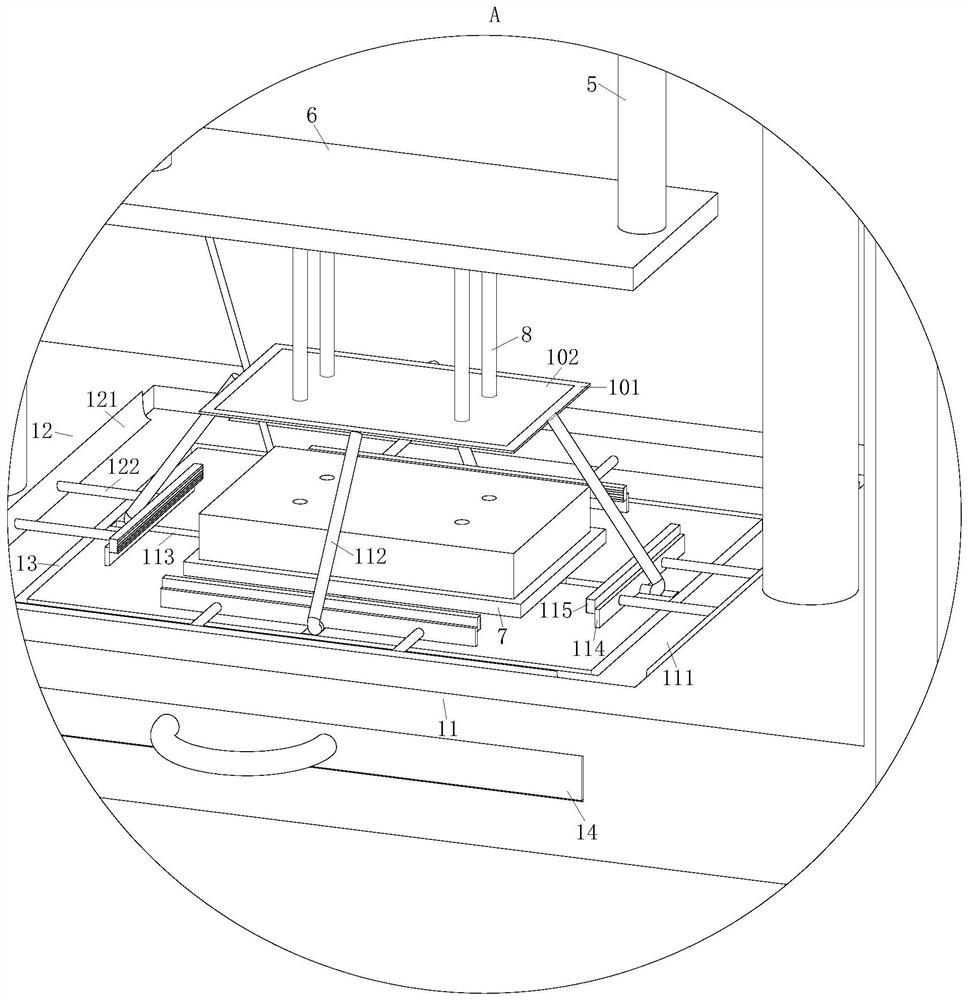

[0029] As an embodiment of the present invention, the closed module 11 includes a groove 111, an elastic rod 112, a chute 113, a sliding strip 114 and a sealing strip 115; a groove 111 is provided at the lower end of the workbench 2; The airtight tooling 7 is placed in the groove 111; four chutes 113 are provided in the groove 111; the four chutes 113 correspond to the four sides of the airtight tooling 7; the test strip housing 101 The edge is provided with a draw-in groove; the lower end of the elastic rod 112 is located in the chute 113, the lower end of the elastic rod 112 is slidably connected with the chute 113, and one end of the elastic rod 112 is engaged with the draw-in groove on the edge of the test strip housing 101, elastic The other end of the rod 112 is fixedly connected with the slide bar 114; the slide bar 114 slides on the surface of the groove 111, and the other end of the top of the slide bar 114 is fixedly connected with a sealing strip 115; during work, be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com